A kind of low apeo nylon coated label tape and preparation method thereof

A nylon coating and trademark belt technology, applied in the field of trademark belt, can solve the problems of difficult to guarantee the effect of APEO remover, unable to fundamentally control APEO, difficult to control APEO, etc., to reduce market competitiveness, reduce sewage discharge, reduce The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

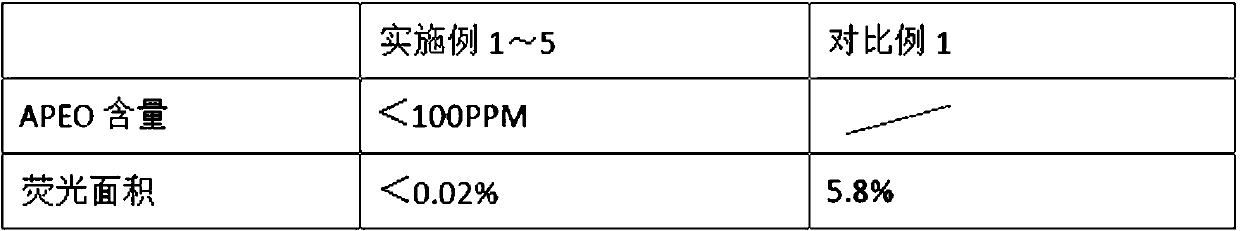

Examples

Embodiment 1

[0029] A low APEO nylon coated label tape, thickness 0.110mm, weight 60g / m 2 , including greige and coating. The gray cloth is made of 30D pure nylon fiber warp yarn and 50D nylon-polyester composite weft yarn. The warp yarn density is 40 threads / cm, the weft thread density is 20 threads / cm, the thickness is 0.090mm, and the weight is 30g / m 2 . The warp yarn of the pure nylon fiber is a single-strand nylon yarn. The nylon-polyester composite weft yarn has a nylon content of 40% and a polyester content of 60%. It is composed of 12 spun yarns, and each yarn of the weft yarn is nylon-wrapped polyester. The coating is coated on the surface of the gray cloth, and the coating glue is prepared from 40 parts of methanol, 5 parts of white carbon black filler, 5 parts of APEO-free nylon 6 particles, and 15 parts of industrial calcium chloride.

[0030]The preparation method of the low-APEO nylon-coated trademark tape is as follows: (1) Gray cloth weaving: use 30D pure nylon fiber warp...

Embodiment 2

[0032] A low APEO nylon-coated label tape with a thickness of 0.118mm and a weight of 78g / m 2 , including greige and coating. The gray cloth is made of 40D pure nylon fiber warp yarn and 60D nylon-polyester composite weft yarn. The warp yarn density is 50 threads / cm, the weft thread density is 30 threads / cm, the thickness is 0.1mm, and the gram weight is 35g / m 2 . The warp yarn of the pure nylon fiber is a single-strand nylon yarn. The nylon-polyester composite weft yarn of the yarn has a nylon content of 42% and a polyester content of 58%. It is composed of 18 spun yarns, and each yarn of the weft yarn is nylon-wrapped polyester. The coating is coated on the surface of the gray cloth, and the coating glue is prepared from 42 parts of methanol, 8 parts of calcium carbonate filler, 8 parts of nylon 6 particles without APEO, and 20 parts of industrial calcium chloride.

[0033] The preparation method of the low-APEO nylon-coated trademark tape is as follows: (1) Gray cloth wea...

Embodiment 3

[0035] A low APEO nylon coated label tape with a thickness of 0.120mm and a weight of 80g / m 2 , including greige and coating. The gray cloth is made of 45D pure nylon fiber warp yarn and 70D nylon-polyester composite weft yarn. The warp yarn density is 55 / cm, the weft yarn density is 32 / cm, the thickness is 0.102mm, and the weight is 40g / m 2 . The warp yarn of the pure nylon fiber is a single-strand nylon yarn. The nylon-polyester composite weft yarn has a nylon content of 45% and a polyester content of 55%. It is composed of 20 spun yarns, and each yarn of the weft yarn is nylon-wrapped polyester. The coating is coated on the surface of the gray cloth, and the coating glue is prepared from 42 parts of methanol, 5 parts of white carbon black filler, 5 parts of calcium carbonate filler, 8 parts of APEO-free nylon 6 particles, and 20 parts of industrial calcium chloride. .

[0036] The preparation method of the low-APEO nylon-coated trademark tape is as follows: (1) Gray clot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com