A light-shielding conductive adhesive and tape with strong shielding performance and preparation method

A technology of conductive tape and conductive adhesive, which is applied in the direction of conductive adhesives, adhesives, adhesive additives, etc., can solve the problems of low electromagnetic shielding efficiency and inability to achieve radiation shielding effects of conductive tapes, and achieve good electromagnetic shielding performance. Excellent stability and conductive shielding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

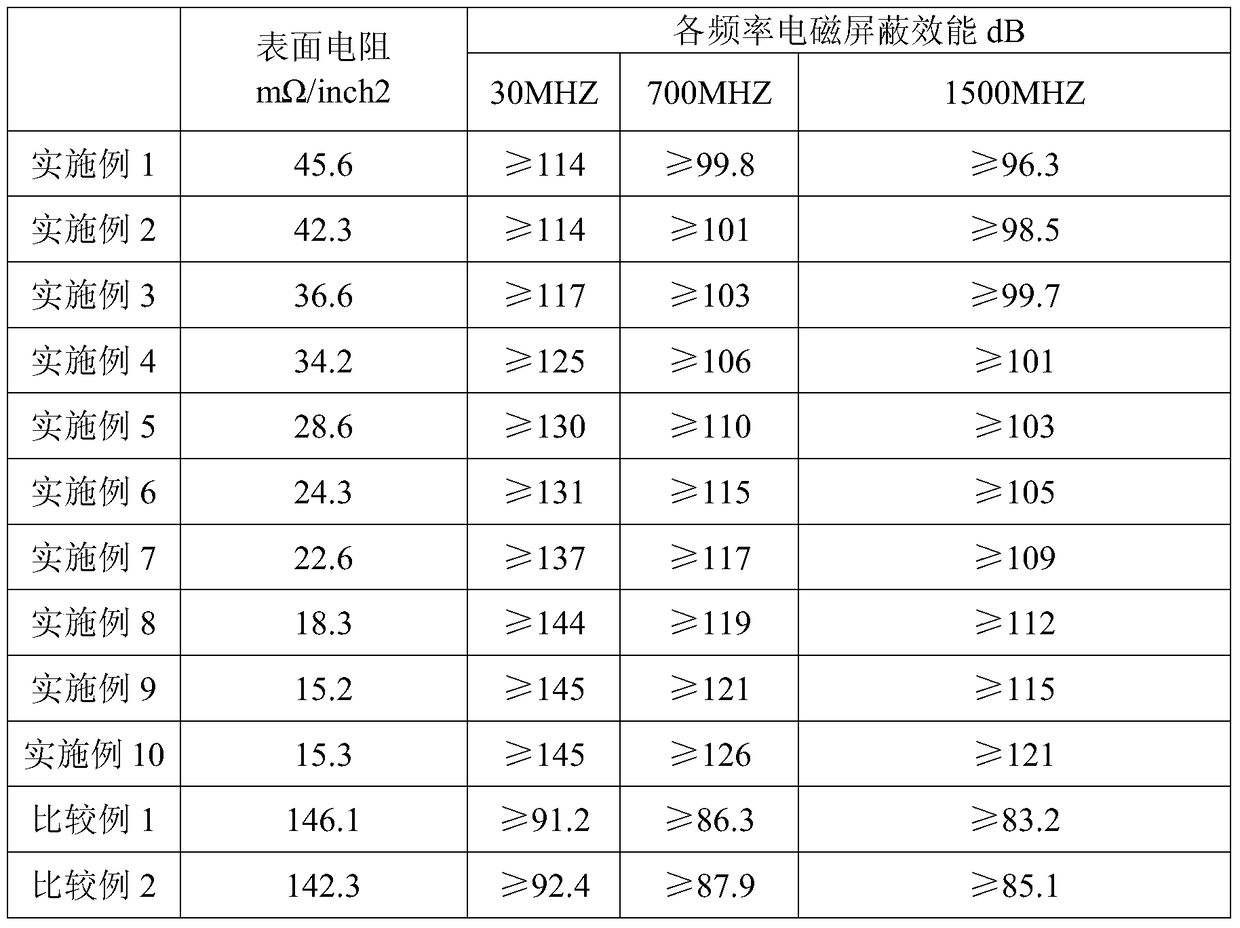

Embodiment 1

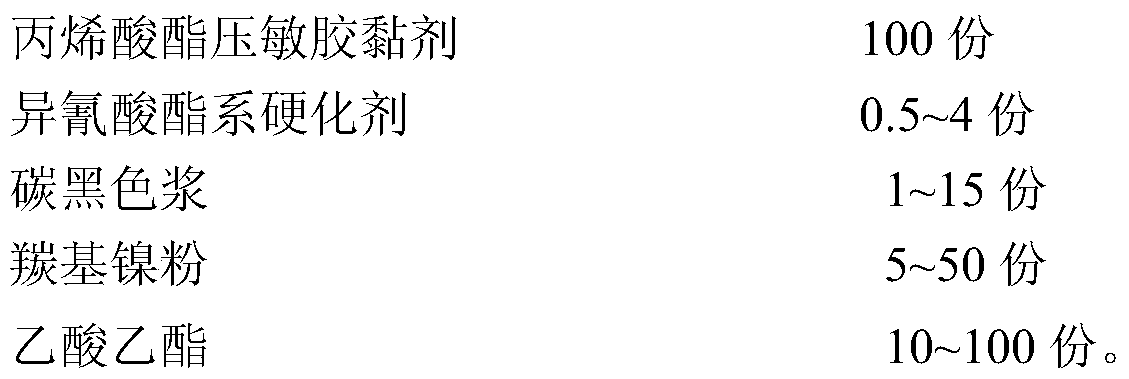

[0029] Preparation of light-shielding conductive adhesive composition:

[0030] Add 0.5 part of toluene diisocyanate and trimethylolpropane adduct (TDI-DMP adduct, produced by BASF, Germany, model: L-75) and 1 part of carbon black paste B807 (produced by Suzhou Shimin Technology Co., Ltd. ) was added to 100 parts of acrylate pressure-sensitive adhesive (produced by Zongyan Chemical Co., Ltd., Ningbo Daxie Development Zone), stirred for 10 minutes to form a mixture, and 5 parts of carbonyl nickel powder T123 (Brazilian Vale company), and then add the wetted nickel carbonyl powder to the above mixture, add the remaining 10 parts of ethyl acetate, and stir for 10 minutes to obtain a uniform and stable light-shielding conductive adhesive composition. Among them, the content of nickel particles in the above-mentioned carbonyl nickel powder is more than 98.5%, and the particle size of nickel particles is 3-5 μm; the content of carbon black in the carbon black slurry is 30%, and the ...

Embodiment 2

[0034] Preparation of light-shielding conductive adhesive composition:

[0035] Add 1 part of toluene diisocyanate and trimethylolpropane adduct (TDI-DMP adduct, produced by BASF, Germany, model: L-75) and 3 parts of carbon black paste B807 (produced by Suzhou Shimin Technology Co., Ltd. ) was added to 100 parts of acrylate pressure-sensitive adhesive (produced by Zongyan Chemical Co., Ltd., company), and then add the wet carbonyl nickel powder into the above mixture, and stir for 15 minutes to obtain a uniform and stable light-shielding conductive adhesive composition. Among them, the content of nickel particles in the above-mentioned carbonyl nickel powder is more than 98.5%, and the particle size of nickel particles is 3-5 μm; the content of carbon black in the carbon black slurry is 40%, and the carbon black with a particle size of 0.5 μm is ground and dispersed , Prepared after dissolving, the acrylate pressure-sensitive adhesive is an acrylate polymer, the average molecul...

Embodiment 3

[0040] Preparation of light-shielding conductive adhesive composition:

[0041] Add 0.9 parts of hexamethylene diisocyanate derivatives (model: BASONAT HB-175, produced by BASF, Germany) and 7 parts of carbon black paste B807 (produced by Suzhou Shimin Technology Co., Ltd.) to 100 parts of acrylate pressure-sensitive adhesive (Ningbo Daxie Development Zone Zongyan Chemical Co., Ltd.), stirred for 20 minutes to form a mixture, wet 15 parts of carbonyl nickel powder T123 (produced by Brazil Vale Corporation) with 20 parts of ethyl acetate, and then wetted the carbonyl Nickel powder was added to the above mixture, and the remaining 10 parts of ethyl acetate were added, and stirred for 20 minutes to obtain a uniform and stable light-shielding conductive adhesive composition. Among them, the content of nickel particles in the above-mentioned carbonyl nickel powder is more than 98.5%, and the particle size of nickel particles is 3-5 μm; the content of carbon black in the carbon blac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com