Turntable transmission structure of electric mop

A technology of transmission structure and turntable, applied in the direction of carpet cleaning, floor cleaning, cleaning equipment, etc., can solve the problems of reducing the service life of the mop, the turntable cannot be driven to rotate, the shaft and the hole transmission structure failure, etc., so as to improve the service life and rotate Smooth, wear-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to further explain the technical means and functions adopted by this application to achieve the predetermined purpose, the specific implementation, structure, features and functions according to this application will be described in detail below in conjunction with the drawings and preferred embodiments. In the following description, different "one embodiment" or "embodiment" do not necessarily refer to the same embodiment. Furthermore, the particular features, structures, or characteristics of one or more embodiments may be combined in any suitable manner.

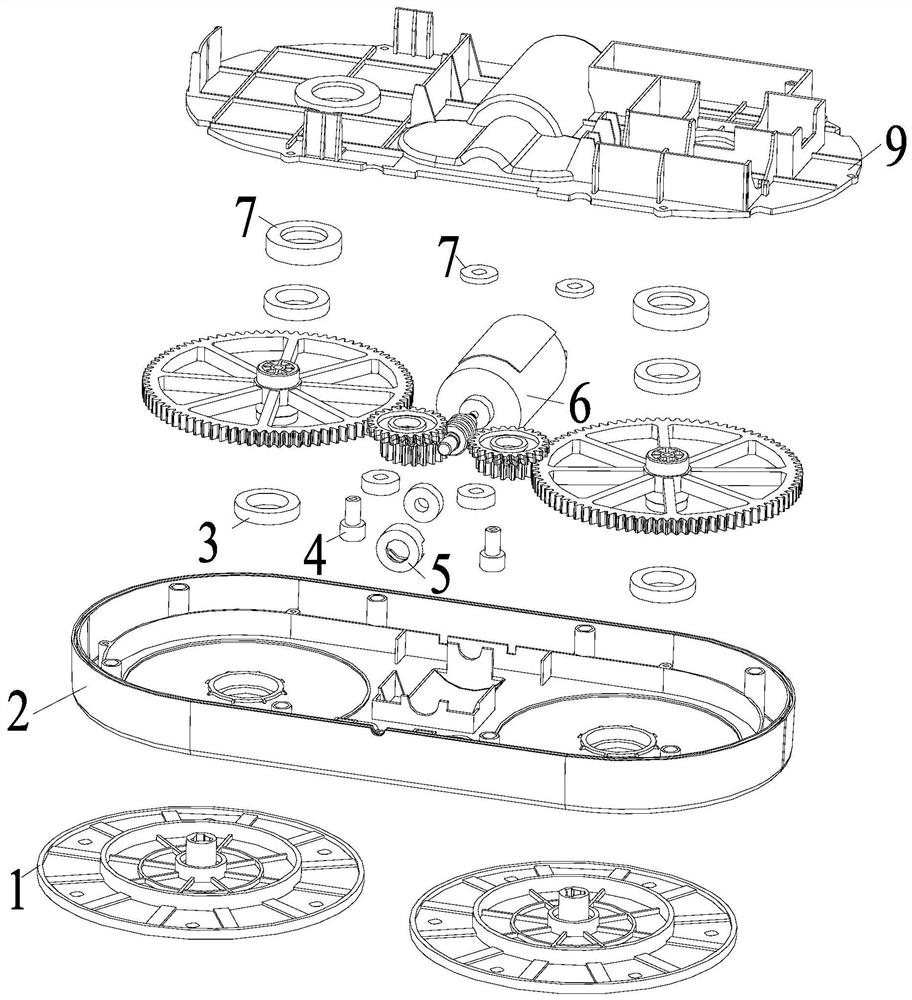

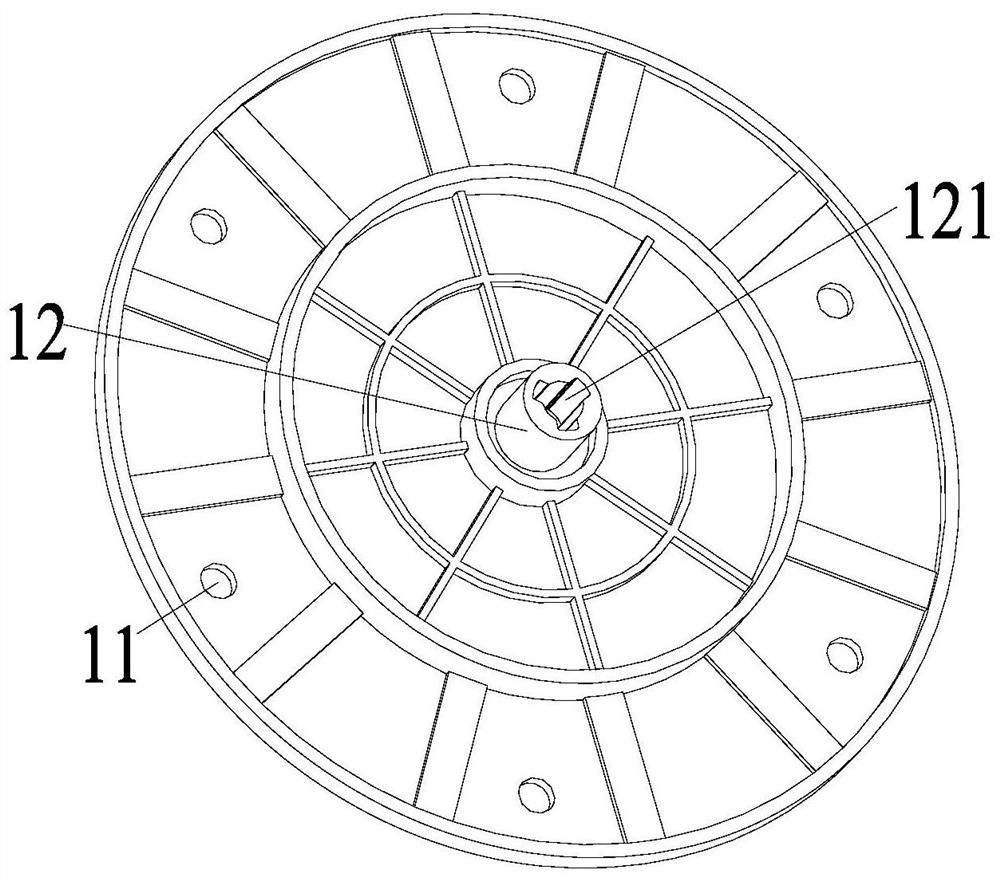

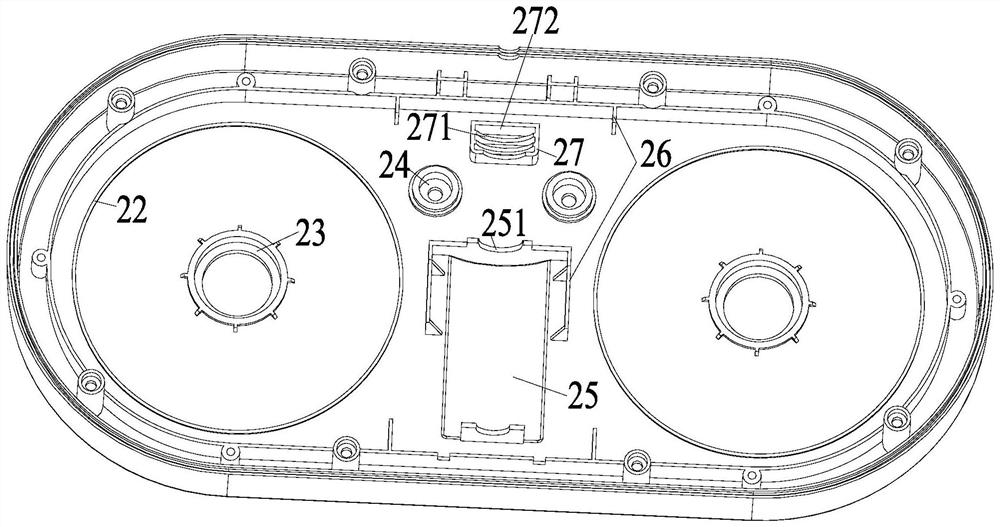

[0032] Such as Figure 1-12 As shown, the present invention provides a turntable transmission structure of an electric mop, which includes a fixedly connected lower casing 2 and a cover plate 9, and a turntable 1 arranged at the lower part of the lower casing 2, between which the lower casing 2 and the cover plate 9 There is a driving gear 63, the upper and lower ends of the driving gear 63 are respective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com