Preparation method of low-back-osmosis absorption article

A technology for absorbent articles and absorbent bodies, which is applied in the field of preparation of low-rewet absorbent articles, can solve problems such as difficulty in keeping the liquid-permeable surface layer dry, easy breakage of the absorbent body, and reduced air permeability, and achieve a strong sense of lightness and mobility. The effect of good sex and increased absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

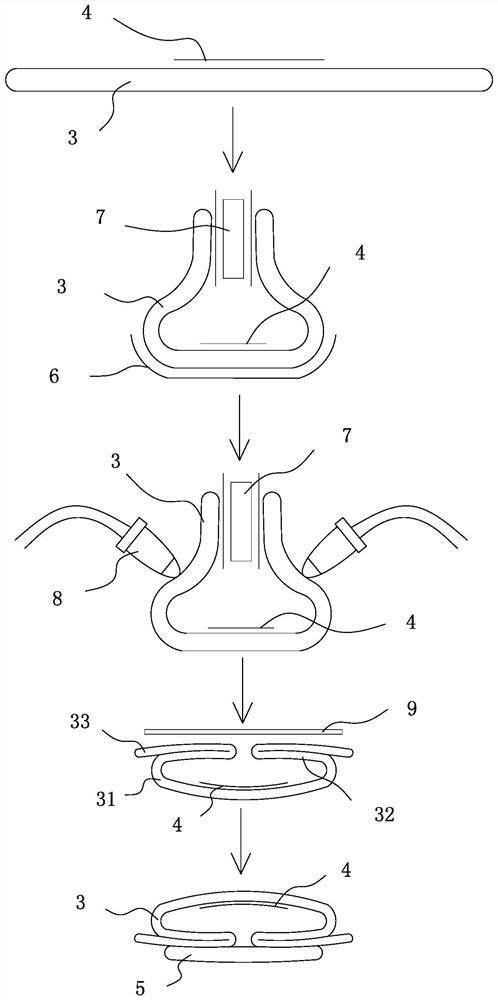

[0039] refer to figure 1 Shown, a kind of preparation method of low rewet absorbent article, comprises the following steps:

[0040] 1) Prepare a liquid-permeable surface layer 1;

[0041] 2) Prepare diversion layer 2;

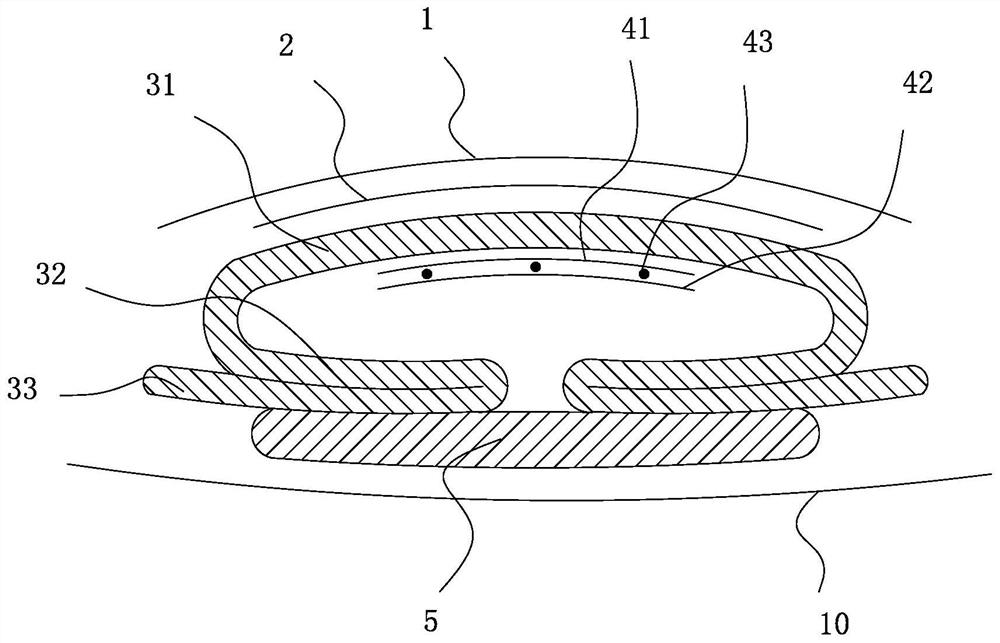

[0042] 3) Preparation of absorbent core layer: refer to figure 2 As shown, the absorbent core layer includes a first absorbent core 3, a tensile elastic sheet 4 and a second absorbent core 5 that are sequentially stacked from top to bottom, and the tensile elastic sheet 4 is adhered to the first absorbent core. The transverse middle of the lower surface of the core 3, which is not bonded to the upper surface of the second absorbent core 5;

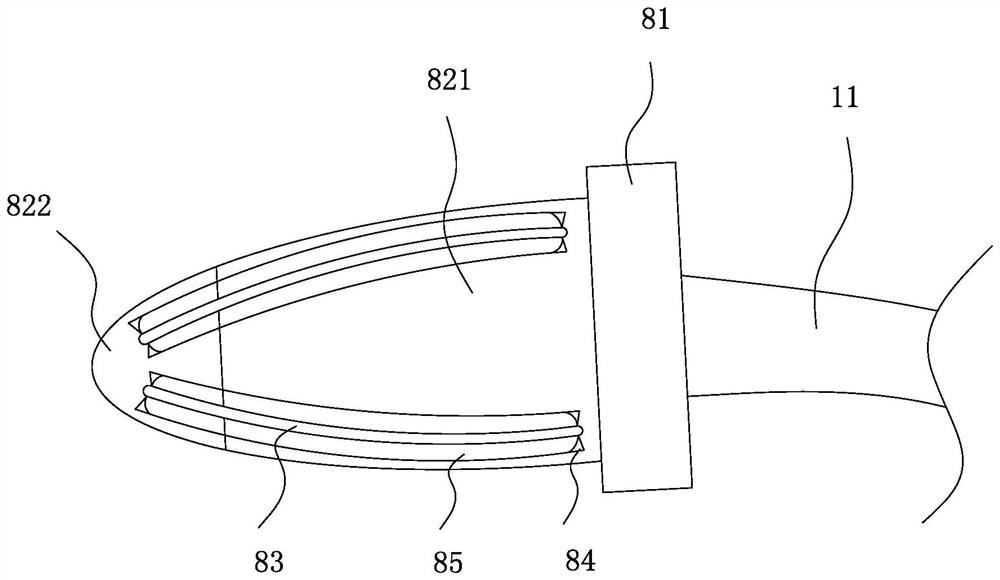

[0043] a. Preparation of the tensile elastic sheet 4: the tensile elastic sheet 4 is sequentially compounded by the upper non-woven fabric 41, the elastic group and the lower non-woven fabric 42, and the elastic group is three stretch ratios distributed side by side along the longitudinal direction 1.8 times the elast...

Embodiment 2

[0065] Embodiment 2 and Embodiment 1 belong to the same inventive concept, and its difference from Embodiment 1 is that the preparation of the diversion layer includes the following steps:

[0066] The sheath-core fiber with a fiber length of 40mm and a fiber fineness of 3D is opened and mixed first, and the opened fiber is sent to the first carding machine through the air-flow feeding box to form a fiber web after repeated carding, and then passed through the stripping roller. The fiber web is peeled off to make a first fiber web composed of single fibers, and the pores between the fibers of the first fiber web are 30 μm;

[0067] The fiber length is 38mm, the fiber fineness is 1D, and the sheath-core fiber that has been treated with hydrophilicity is firstly opened and mixed, and the opened fiber is sent to the second carding machine through the air-flow feeding box for repeated carding to form fibers The web is peeled off by a stripping roller to form a second messy web com...

Embodiment 3

[0077] Embodiment 3 and Embodiment 1 belong to the same inventive concept, and its difference from Embodiment 1 is that the preparation of the diversion layer includes the following steps:

[0078] The sheath-core fiber with a fiber length of 36mm and a fiber fineness of 4D is firstly opened and mixed, and the opened fiber is sent to the first carding machine through the air-flow feeding box to form a fiber web after repeated carding, and then passed through the stripping roller. peeling off the fiber web to make a first fiber web composed of single fibers, and the pores between the fibers of the first fiber web are 30 μm-60 μm;

[0079] The fiber length is 50mm, the fiber fineness is 2D, and the sheath-core fiber that has been treated with hydrophilicity is firstly opened and mixed, and the opened fiber is sent to the second carding machine through the air-flow feeding box for repeated carding to form fibers The web is peeled off by a stripping roller to form a second fiber w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com