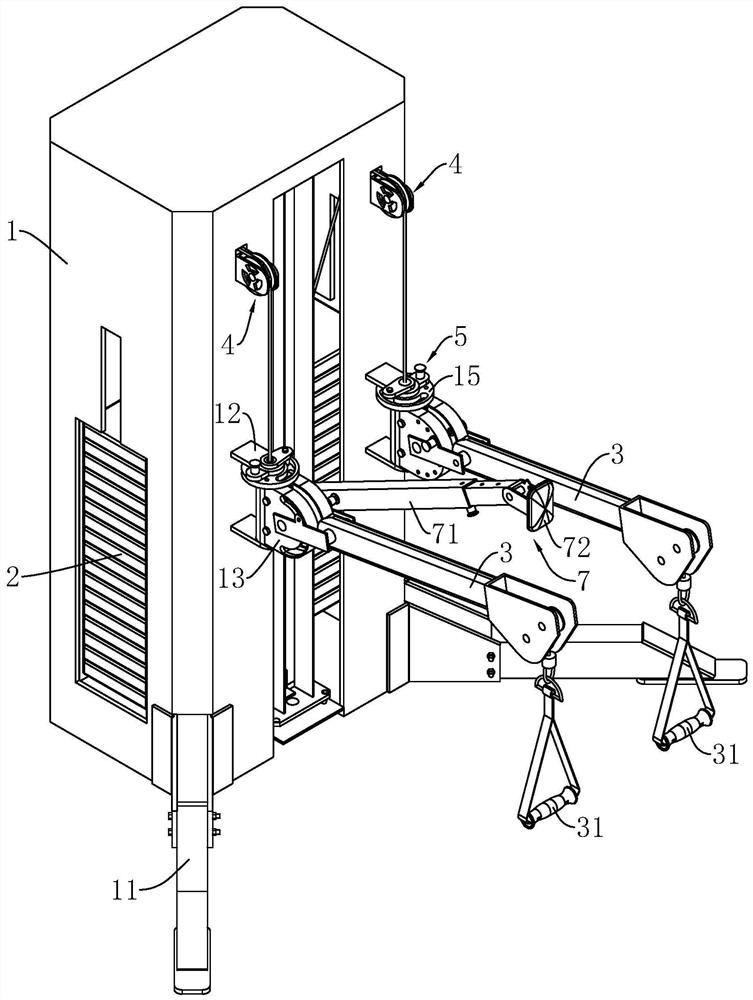

Multifunctional weight training machine

A training machine and multi-functional technology, applied in the direction of muscle training equipment, sports accessories, gymnastics equipment, etc., can solve the problem of less fitness equipment, achieve convenient exercise, improve comprehensive and functional effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

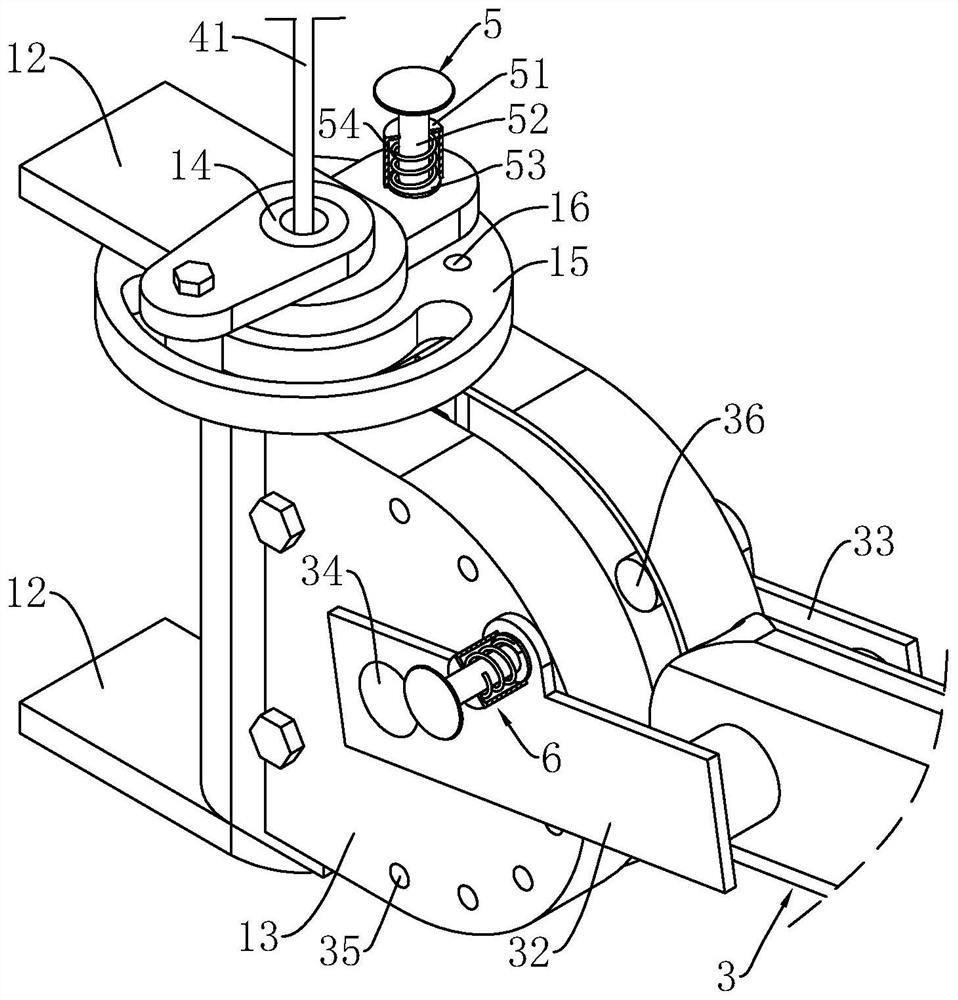

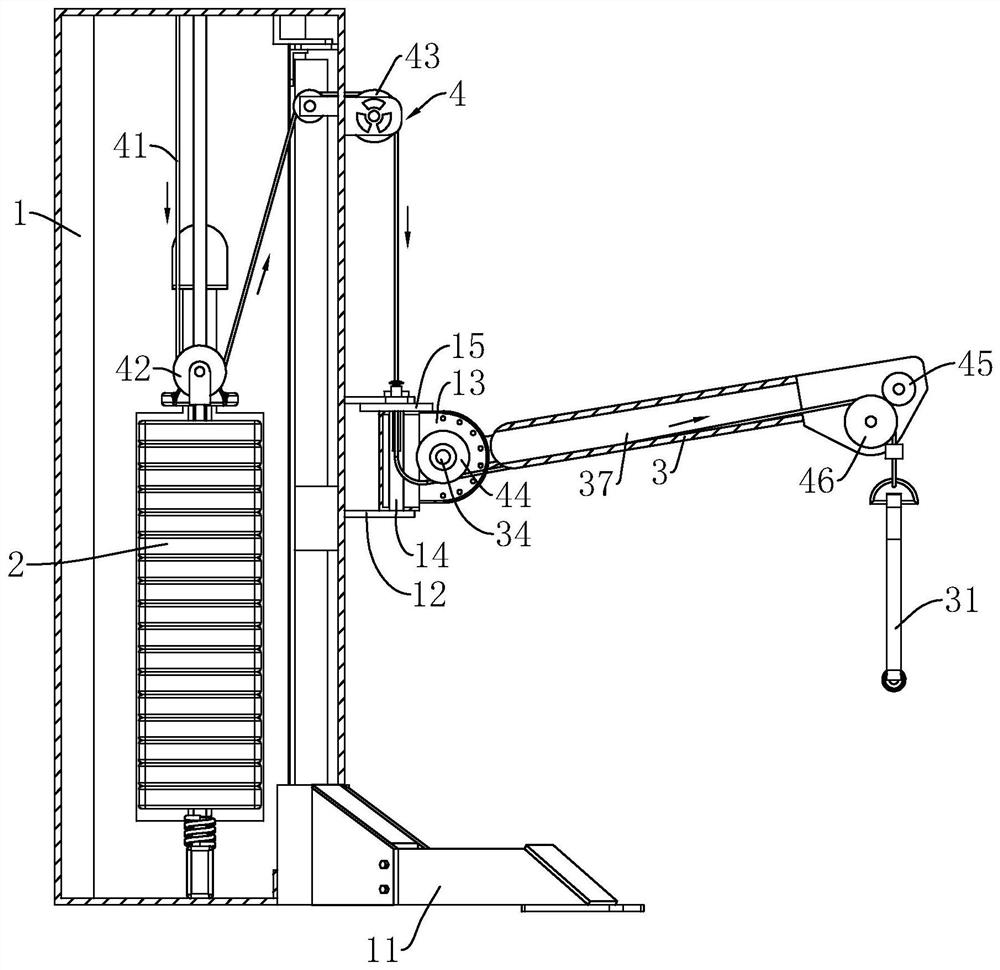

[0053] refer to Figure 4 The difference between this embodiment and Embodiment 1 is that a connecting frame 38 is rotatably installed at the free end of the force applying arm 3 , and the third fixed pulley 45 and the fourth fixed pulley 46 are installed in the connecting frame 38 .

[0054] Specifically, the connecting frame 38 also has an installation cavity inside, and the third fixed pulley 45 and the fourth fixed pulley 46 are installed in the installation cavity; one side of the connecting frame 38 is fixed with a connecting pipe 39, and the connecting pipe 39 and the connecting frame 38 The installation cavity is connected; the axial direction of the connecting pipe 39 is the same as the length direction of the force applying arm 3, and is installed in the wiring channel 37 of the force applying arm 3 through the bearing, so that the connecting frame 38 can rotate around the axis of the connecting pipe 39, and the connecting frame is improved. 38 degrees of flexibility...

Embodiment 3

[0057] refer to Figure 5 The difference between this embodiment and Embodiment 1 is that the installation angle of the back support 7 on the main frame 1 is adjustable.

[0058] Specifically, the side wall of the main frame 1 is provided with a mounting groove 17; the hinged end of the support rod 71 is provided with a third connection shaft horizontally, and the free end of the support rod 71 is provided with a fourth connection shaft; the support rod 71 passes through the third connection shaft. The connecting shaft is rotatably installed in the installation groove 17 , and the support base 72 is rotatably installed on the support rod 71 through the fourth connecting shaft.

[0059] A first support plate 73 is fixed at the hinged end of the support rod 71, and a third fixing component 74 is installed on the first support plate 73; A support plate 73 is provided with an escape hole for the third push rod to pass through, the third stop ring is pressed against the surface of...

Embodiment 4

[0066] refer to Image 6The difference between this embodiment and Embodiment 3 is that the back support 7 can be accommodated in the main frame 1 .

[0067] Specifically, the side of the main frame 1 facing the exercise area is provided with an opening, so that the installation cavity of the main frame 1 communicates with the outside; the main frame 1 is respectively fixed with a mounting plate 18 at both ends of the top and bottom of the opening, and the two mounting plates 18 A storage plate 8 is arranged therebetween, and the storage plate 8 is rotatably connected to the mounting plate 18 through a vertically arranged rotating shaft. One side of the receiving plate 8 is flat, and the installation groove 17 is provided on the opposite side of the plate surface; the receiving plate 8 can be rotated to be flush with the surface of the main frame 1 .

[0068] A bottom plate 81 is horizontally fixed to the bottom of the receiving plate 8 , and two sets of limiting holes 82 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com