Rare earth metal-organic framework material catalyst and preparation and application thereof

A rare earth metal, organic framework technology, applied in the preparation of organic compounds, organic compound/hydride/coordination complex catalysts, catalytic reactions, etc., can solve the problems of non-recyclability, low catalytic efficiency, etc., to solve the problem of poor recyclability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

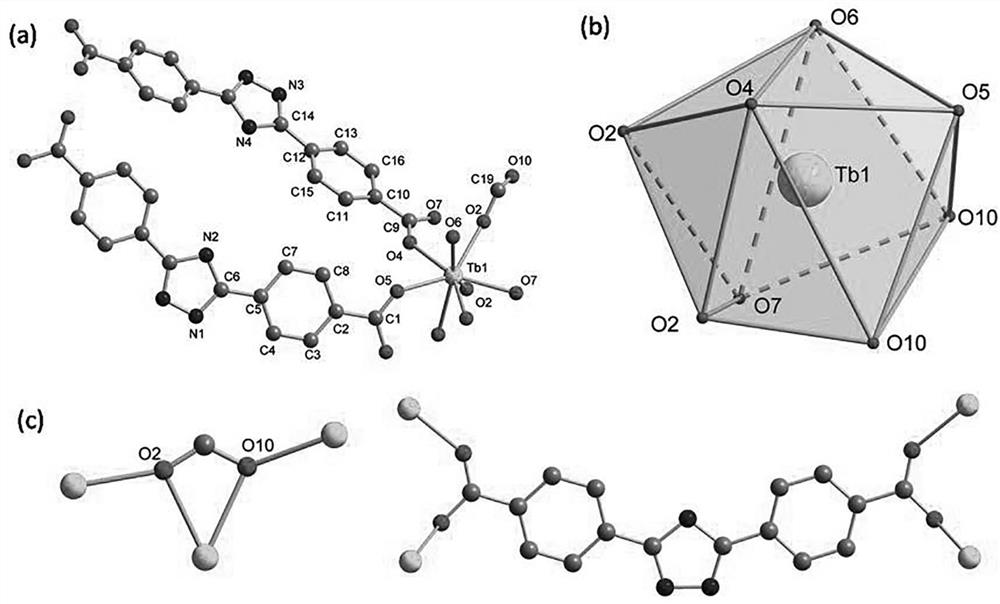

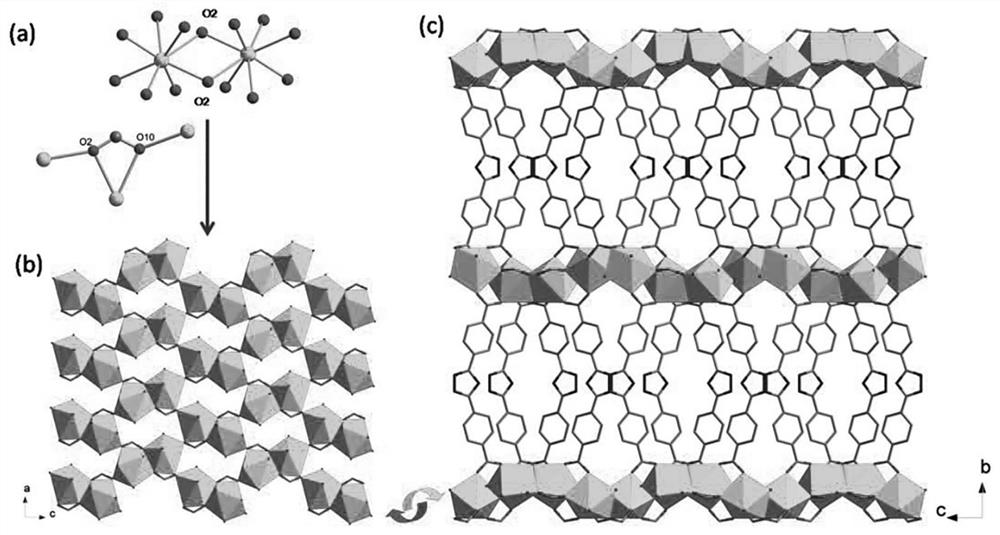

Embodiment 1

[0027] 0.067 mmol of Tb(NO 3 ) 3 and 0.129 mmol of H 2 bct was placed into a container containing 6 ml DMF and 4 ml H 2 O in a Teflon-lined reactor and with 6 mol per liter of HNO 3 Adjust the pH of the solution to 4, stir for half an hour, put it into a reaction kettle, and place it in an oven at 170° C. for 3 days. The filter cake was obtained after suction filtration, and dried to constant weight in a dry atmosphere to obtain the active component of catalyst 1.

Embodiment 2

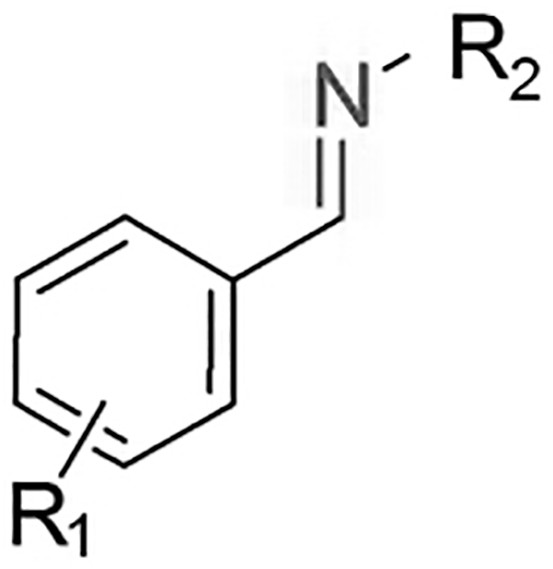

[0028] Example 2: Catalyzed Strecker Reaction of Aldimines

[0029] The trimethylsilyl cyanide of 0.125 millimoles, the catalyst 1 of 0.008 millimoles ([Tb 2 (HCOO) 2 (bct) 2 ]) and 0.05 mmol of aldimine were added sequentially to 0.5 ml of CDCl 3 of a standard 5mm NMR tube. Afterwards, the NMR tubes were capped and sealed with Teflon tape, and then inserted into a constant temperature water bath shaker at room temperature. This response passes 1 H-NMR spectroscopic monitoring, the conversion of the product was determined according to the ratio of the integral of the product signal to the sum of the integrals of all signals (aldimine and product).

[0030] The reaction results of catalyst 1 in Example 2 are shown in Table 1.

[0031] Table 1: Strecker reaction of aldimine with trimethylsilylcyanide catalyzed by metal catalysts

[0032]

[0033]

[0034]

[0035] a Reaction conditions: aldimine (0.05 mmol), TMSCN (0.125 mmol), catalyst3 (0.008 mmol), CDCl 3 (...

Embodiment 3

[0037] 0.067 mmol of Eu(NO 3 ) 3 and 0.129 mmol of H 2 bct was placed into a container containing 6 ml DMF and 4 ml H 2 O in a Teflon-lined reactor and with 6 mol per liter of HNO 3 Adjust the pH of the solution to 4, stir for half an hour, put it into a reaction kettle, and place it in an oven at 170° C. for 3 days. The filter cake was obtained after suction filtration, and dried to constant weight in a dry atmosphere to obtain the active component of catalyst 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com