Sn nano half-crescent particle-2DLMG composite material synthesized by utilizing organic molecular confinement reaction and method

A nanoparticle, nanotechnology, applied in the direction of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, which can solve problems such as expensive, environmentally damaging, complex, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example

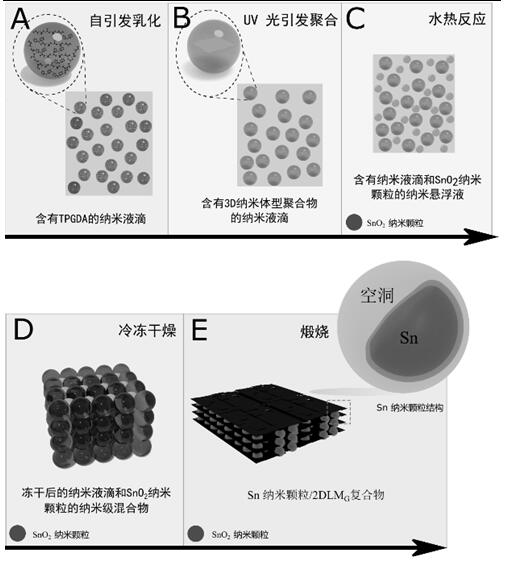

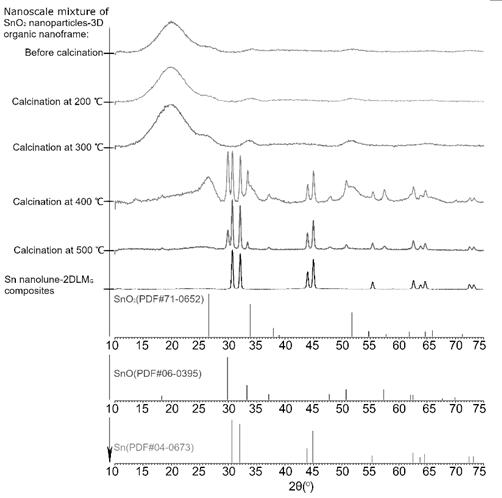

[0037] According to the principle of the present invention, a preferred preparation example of Sn nano-half crescent particle-graphene nanosheet (2DLMG) composite material is provided below, the steps are as follows:

[0038] (1) Synthesis of 3D organic nanoframes in nanodroplets. The whole process is briefly described as follows: 50 wt.% TPGDA (monomer), 5 wt.% HCPK (photoinitiator, relative to the amount of TPGDA) and 50 wt.% Labrafac® WL 1349 were mixed as an oil phase. Then, Kolliphor ELP (hydrophilic surfactant) was added to the oil phase and mixed by a vortex mixer. Afterwards, water was quickly poured into the above mixed phase for spontaneous emulsification. Control the ratio of surfactant, oil phase and water phase in the nanoemulsion to 3:3:4. Once the nanoemulsion is formed, due to its confinement effect, the TPGDA in the nanodroplets is photopolymerized to form a 3D nanoorganic framework.

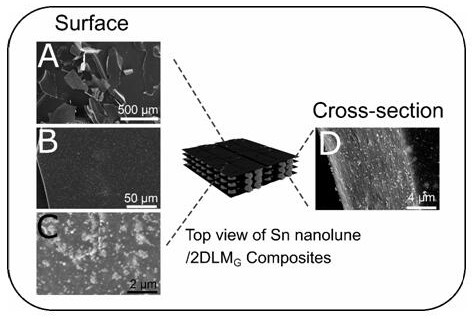

[0039] (2) Sn nano-half-moon particles were infiltrated into 2DLMG to synt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com