Method for preparing internal separation synthesis gas by chemical chain gasification of solid fuel

A solid fuel and chemical chain technology, applied in chemical instruments and methods, using solid contact hydrogen separation, hydrogen separation, etc., can solve the problems of reduced active components, increased reaction load, increased oxygen carrier amount, etc., to achieve good The effect of cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] BaFe 2 o 4 / NiFe 2 o 4 / CoFe 2 o 4 / CaFe 2 o 4 The preparation method of oxygen carrier comprises the following steps:

[0046] Step 1: Barium nitrate / nickel nitrate / cobalt nitrate / calcium nitrate, ferric nitrate and citric acid (Ba 2+ / Ni 2+ / Co 2+ / Ca 2+ -Fe 3+ - the molar ratio of citric acid is 1:2:2) mixed in deionized water at 50°C, and stirred for 6h;

[0047] Step 2: adjust the pH of the solution obtained in step 1 to 7 with ammonia water;

[0048] Step 3: Stir the solution obtained in Step 2 at 80°C until it reaches a gel state;

[0049] Step 4: Dry the gel obtained in Step 3 in an oven at 120°C for 12 hours;

[0050] Step 5: Put the solid obtained in Step 4 in a muffle furnace, and heat it up to 450° C. for 2 hours at a heating rate of 10° C. / min in an air atmosphere;

[0051] Step 6: Grind and mix the solid obtained in Step 5 in a ball mill (clockwise for 1 hour, counterclockwise for 1 hour, pause for 10 minutes).

[0052] Step 7: Put the soli...

Embodiment 2

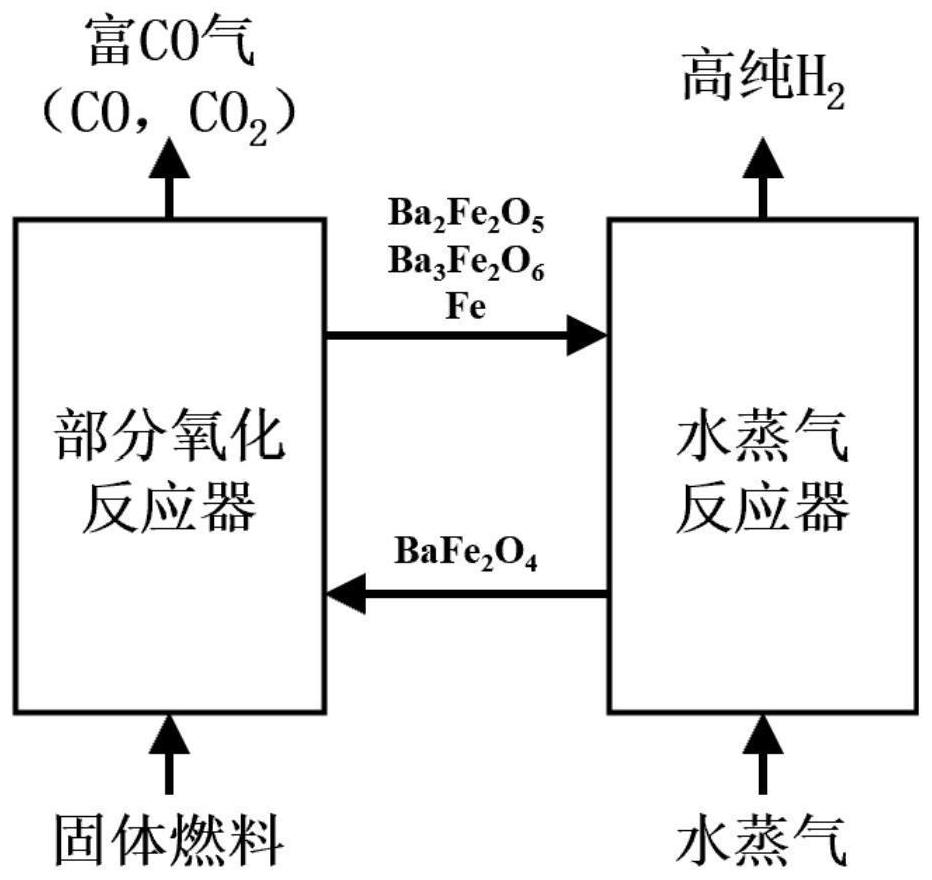

[0055] A method for preparing internally separated synthesis gas by chemical looping gasification of solid fuel, comprising the following steps:

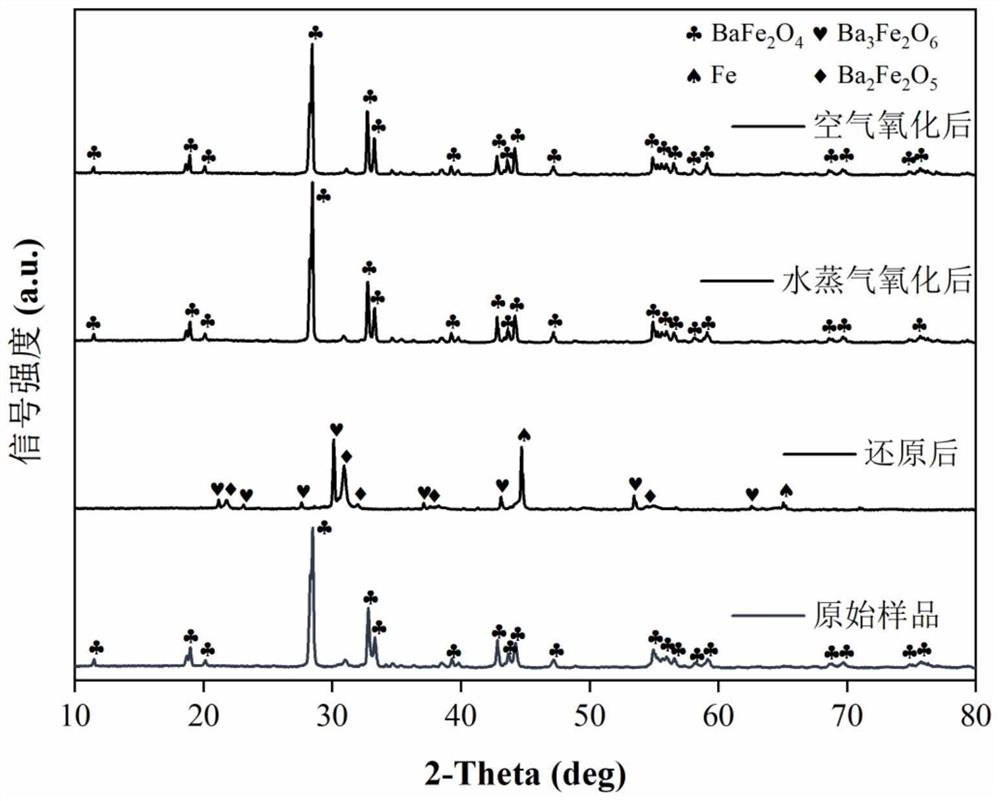

[0056] Step 1: with the BaFe that embodiment 1 makes 2 o 4 The oxygen carrier is mixed with the biomass coke (the molar ratio of the C element in the biomass coke to the O element in the oxygen carrier is 1:2), and placed in a partial oxidation reactor for redox reaction, the reaction temperature is 900°C, and the reaction The time is 1h, and the CO-enriched gas is collected;

[0057] Step 2: Send the reduced oxygen carrier into the steam reactor for steam cracking reaction, the reaction temperature is 900°C, the reaction time is 40min, and high-purity H 2 ;

[0058] Step 3: Send the oxygen carrier regenerated in step 2 into the air oxidizer to fully oxidize the oxygen carrier. The reaction temperature is 900°C and the reaction time is 30 minutes.

[0059] Collect tail gas and solid products, measure carbon conversion rate, CO y...

Embodiment 3

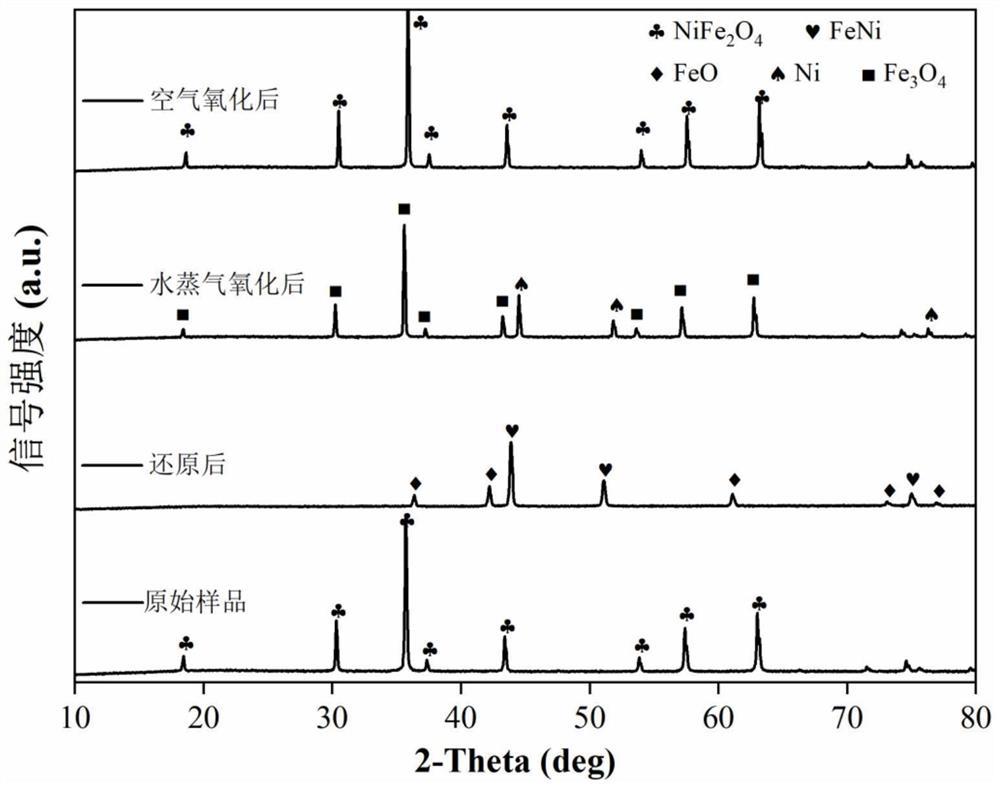

[0061] Compared with embodiment 2, adopt NiFe in the present embodiment 2 o 4 Oxygen carrier, all the other steps are the same as in Example 2.

[0062] Collect tail gas and solid products, measure carbon conversion rate, CO yield, CO selectivity, H 2 Yield and H 2 Purity, measurement results see Table 1, observe NiFe 2 o 4 The phase transition of the oxygen carrier, see the phase transition results image 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com