Plate stamping system and machining method thereof

A sheet metal and stamping die technology, applied in the field of door panel processing equipment, can solve problems such as inability to stamp equipment processing operations, reduce equipment processing efficiency, affect work efficiency, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

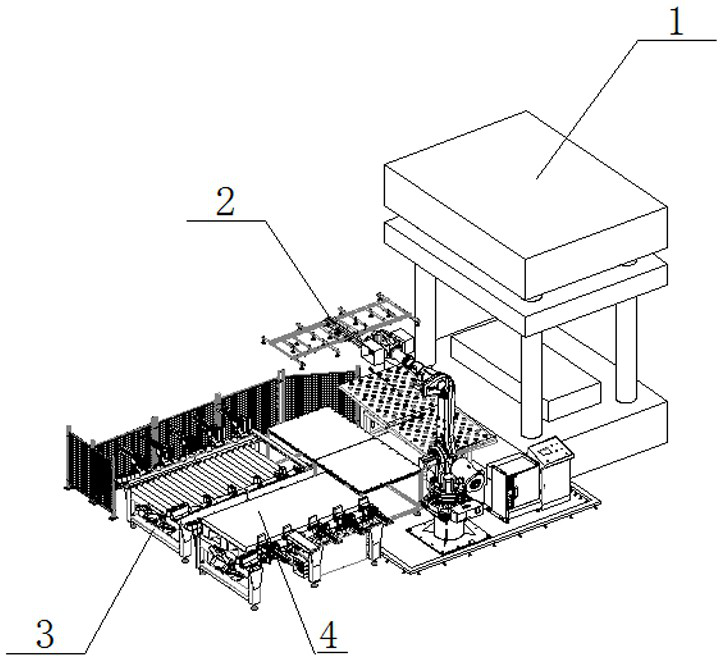

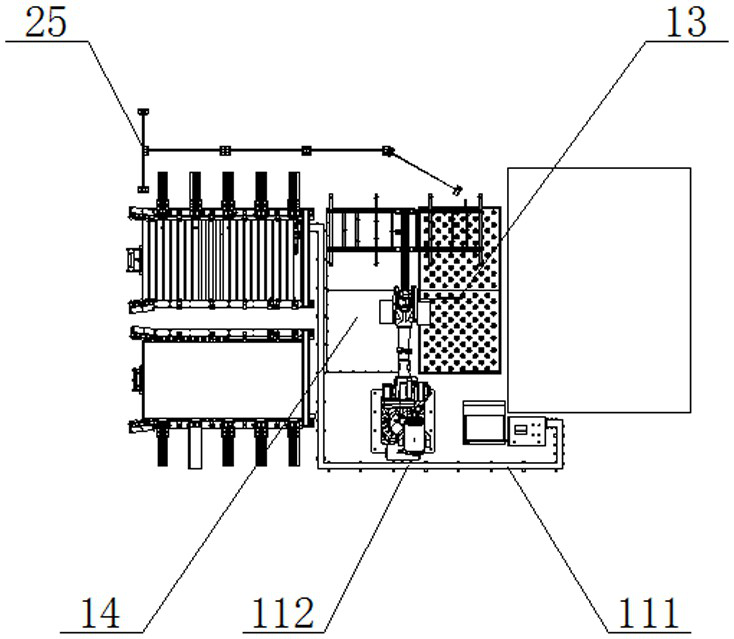

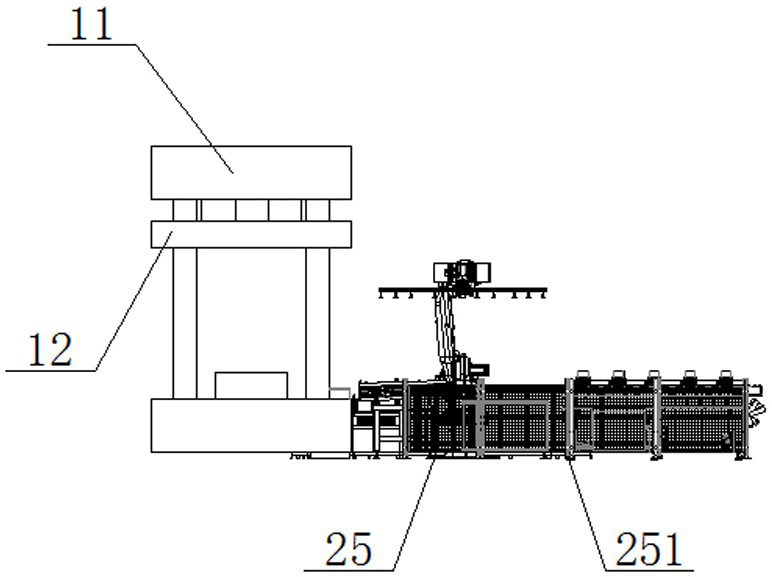

[0046] refer to figure 1 , figure 2 and image 3 As shown, the plate stamping system of this embodiment includes a feeding mechanism 4, a transfer mechanism 2, a stamping die set 1 and a blanking mechanism 3, the stamping die set 1 includes a press 11 and a moving die 12, and the moving die 12 is formed by the press 11 is driven for stamping, the transfer mechanism 2 is set on the side of the stamping die set 1, the unloading mechanism 3 is set on the side of the transfer mechanism 2, and the side of the press 11 is also equipped with a centering die set and a transfer platform 14, and the transfer platform 14 is set On the side of the centering module, the transfer mechanism 2 transfers the door panels on the feeding mechanism 4 to the centering module for centering and then transfers to the stamping module 1. When the unloading backlog, the transfer mechanism 2 transfers the stamped plates Transferring to the transfer platform 14 for temporary storage solves the problem t...

Embodiment 2

[0051] The plate stamping system of this embodiment is basically the same as that of Embodiment 1, the difference is that the centering module is an inclined frame type centering platform 15, the details are as follows:

[0052] Such as Figure 17 and 18 As shown, the inclined frame type centering platform 15 of the present embodiment includes a positioning platform 151 and an inclined frame group 152. The inclined frame group 152 is installed on the lower end surface of the positioning platform 151, and the inclined frame group 152 is fixedly connected with the positioning platform 151. The frame group 152 comprises a square frame 153, a high pole 154, a middle pole 155 and a low pole 156. The high pole 154 and the low pole 156 are respectively arranged on the opposite corners of the square frame 153, and the middle pole 155 is installed on the other two sides of the square frame 153. On the diagonal, and the high pole 154, the middle pole 155 and the low pole 156 are all ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com