Length compact type automatic car washing device and car washing mode thereof

An automatic car washing and compact technology, applied in the field of car washing machines, can solve the problems of large area of car washing machines and long conveying length of flat chain, so as to ensure the quality and efficiency of car washing, reduce the floor space and improve the efficiency of car washing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

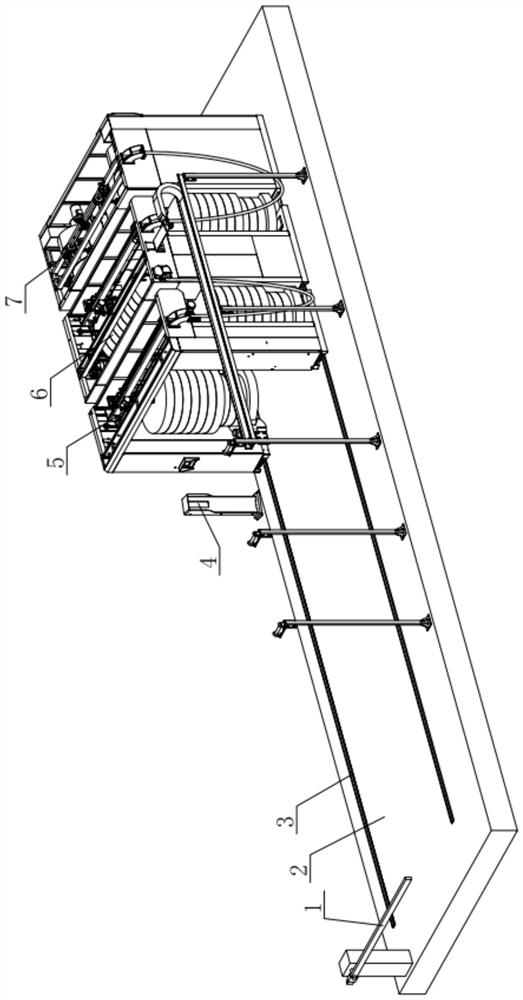

[0048] Such as figure 1 As shown, a compact length automatic car washing device of this embodiment includes a foundation 2, on which rails 3 are installed at intervals, and the two rails 3 are jointly slid from front to back and installed with a gantry cleaning component-5, a gantry cleaning component Two 6 and the gantry drying assembly 7, a railing assembly 1 is installed on the foundation 2 outside the front end of the track 3, and the vehicle to be washed is parked between the two tracks 3 and in the middle of the length direction;

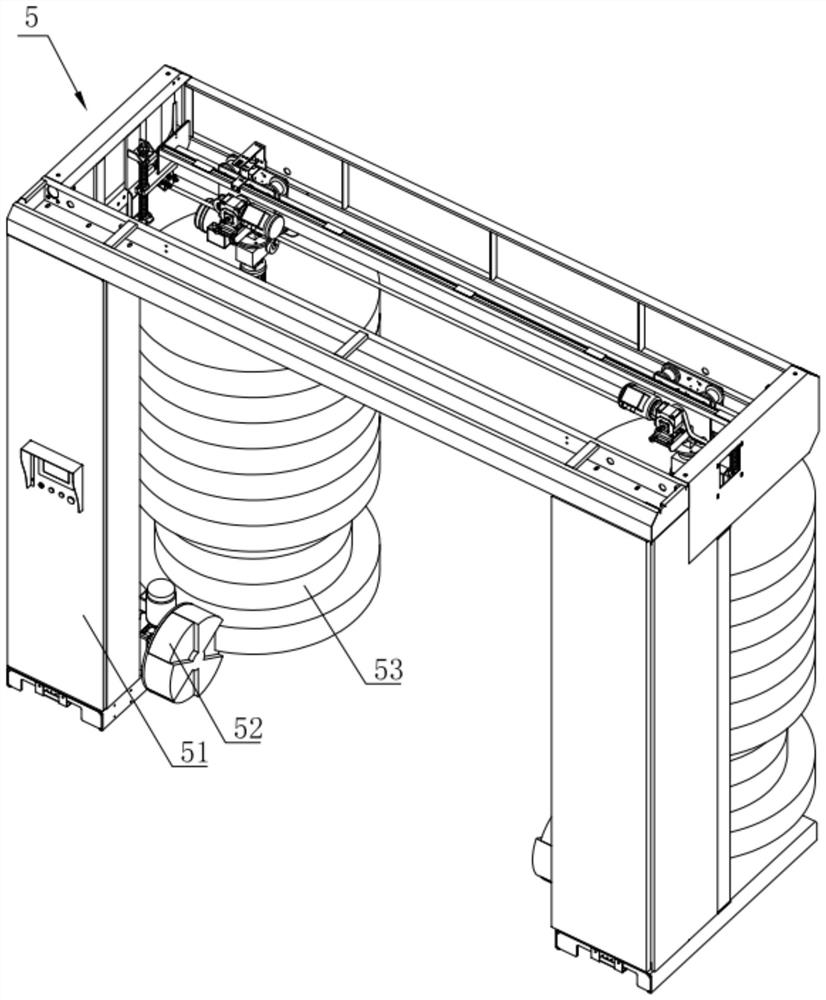

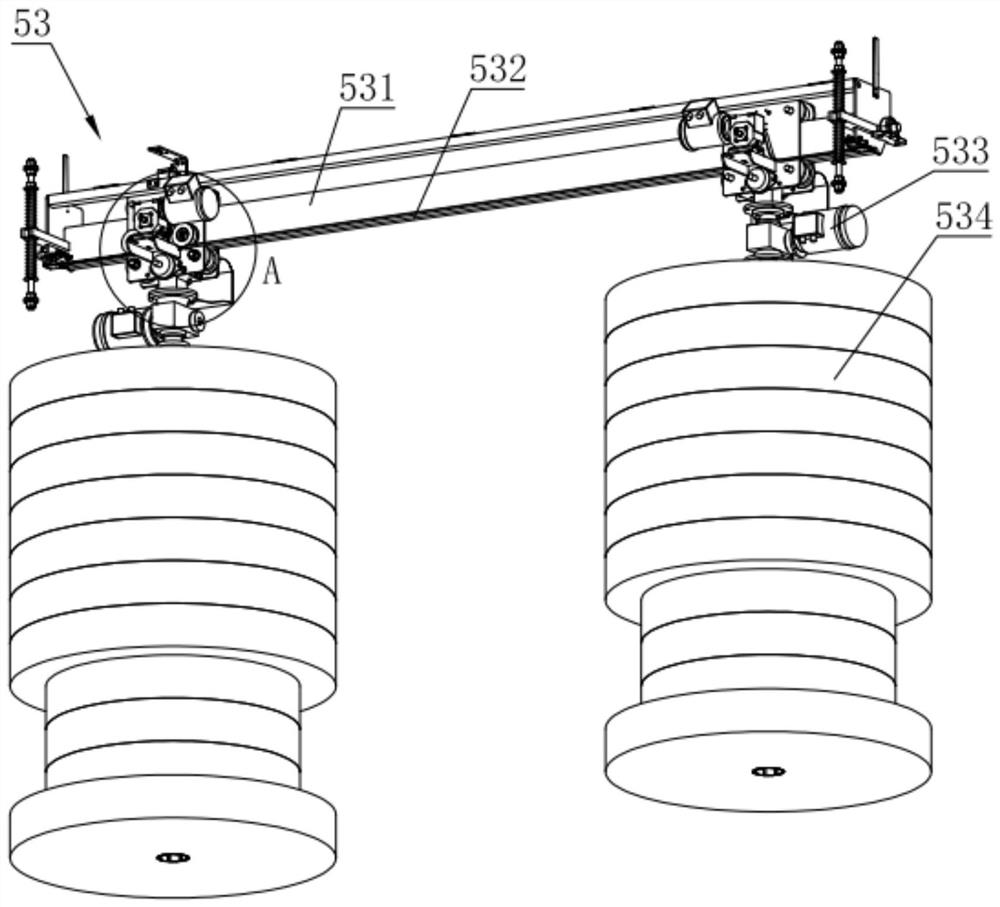

[0049] Such as figure 2 As shown, the structure of the gantry cleaning assembly 1 5 is as follows: a gantry A51 slidingly straddled on the rails 3 on both sides is included, side brush assemblies 53 are symmetrically installed on both inner surfaces of the gantry A51, and the lower part of the gantry A51...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com