Water-based paint filling equipment for polymer paint

A water-based paint and filling equipment technology, applied in packaging, liquid materials, transportation and packaging, etc., can solve the problems of weight deviation of filling, incomplete attachment of paint, continuous and smooth discharge and filling of paint, etc. Achieve smooth filling and reduce the effect of being unable to attach

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

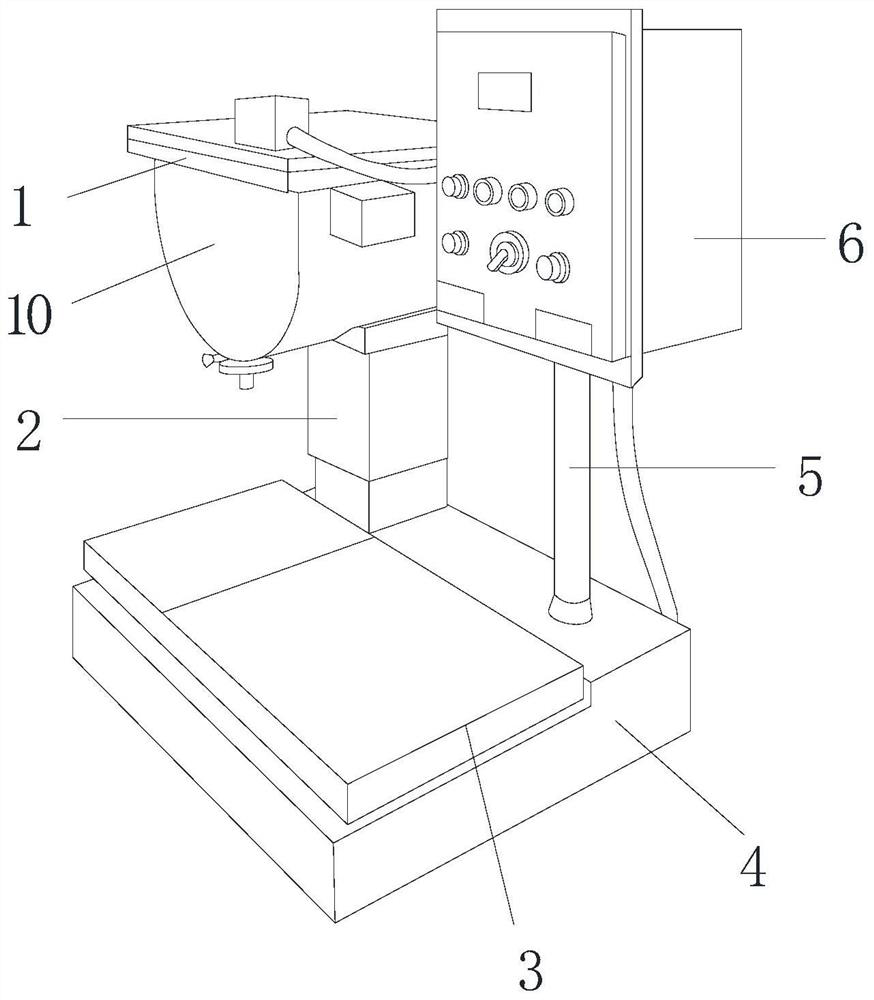

[0027] see Figure 1-Figure 5 , a water-based paint filling equipment for polymer paints, the invention provides a water-based paint filling equipment for polymer paints, the structure of which includes a filling box 1, a filling support column 2, an operation panel 3, a base 4, a support Rod 5, filling control box 6, the filling box 1 is fixed on the filling support column 2, the bottom end of the filling support column 2 is set on the base 4, and the operation panel 3 is set on the base 4 On the surface, the support rod 5 sets the filling control box 6 on the base 4, and the filling control box 6 is set on the side of the filling box 1, and is tightly connected by electricity;

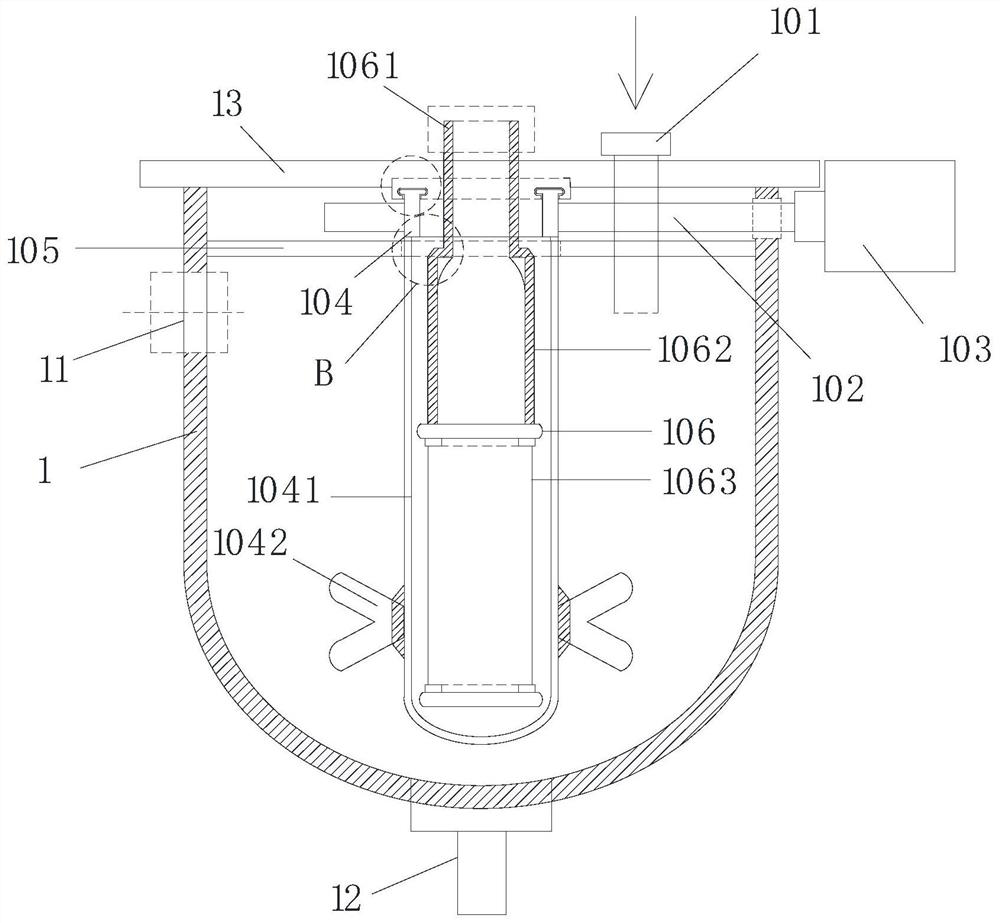

[0028] The filling box 1 is provided with a pressurized defoaming device 10, a paint feed end 11, a filling port 12, and a top cover 13. The paint feed end 11 is located above the inside of the filling box 1, and the pressurized The defoaming device 10 is set inside the filling box 1, the filling po...

Embodiment 2

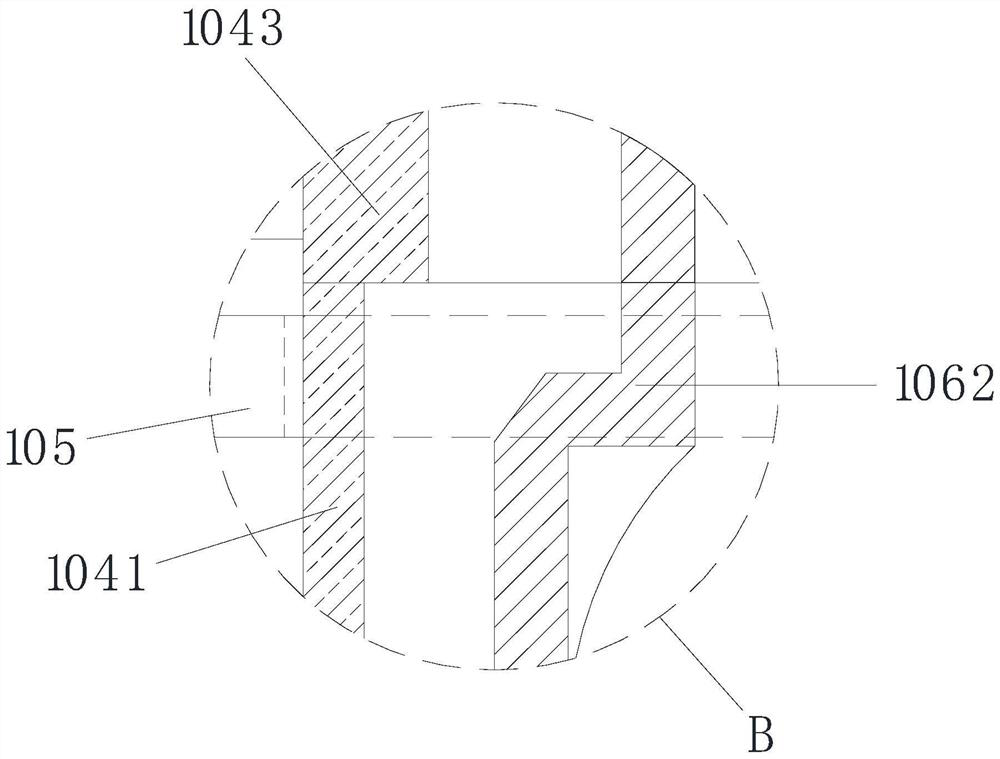

[0035] see Figure 7 , a water-based paint filling equipment for polymer paints, the present invention provides a water-based paint filling equipment for polymer paints, its structure includes an air outlet riser 1062, the cross section of the air outlet riser 1062 is circular, the The top of the air outlet rising pipe 1062 is provided with an air outlet device 1061. The air outlet device 1061 includes a sealing cover 1a, a retractable torsion spring wire 1b, and a connecting ring 1c. The connecting ring 1c is fixed on the outer surface of the air outlet rising pipe 1062. One end of the retracted torsion spring wire 1b is connected to the connecting ring 1c, and the other end is connected to the sealing cover 1a, and the sealing cover 1a is circular and arranged on the top surface of the air outlet rising pipe 1062.

[0036] The bottom surface of the sealing cover 1a is also provided with a sealing piece 1d, the sealing piece 1d is circular, the diameter of the sealing piece 1...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap