Boxing device and method for steel annularly-wound gas cylinders

A hoop winding and gas cylinder technology, applied in the field of packaging, can solve problems affecting product quality and delivery efficiency, product appearance damage, heavy workload, etc., to achieve simple and reliable packing methods, shorten packing time, and improve efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The implementation of the present invention will be described in detail below in conjunction with the examples of implementation, but they do not constitute a limitation of the present invention, and are only examples. At the same time, the advantages of the present invention will become clearer and easier to understand.

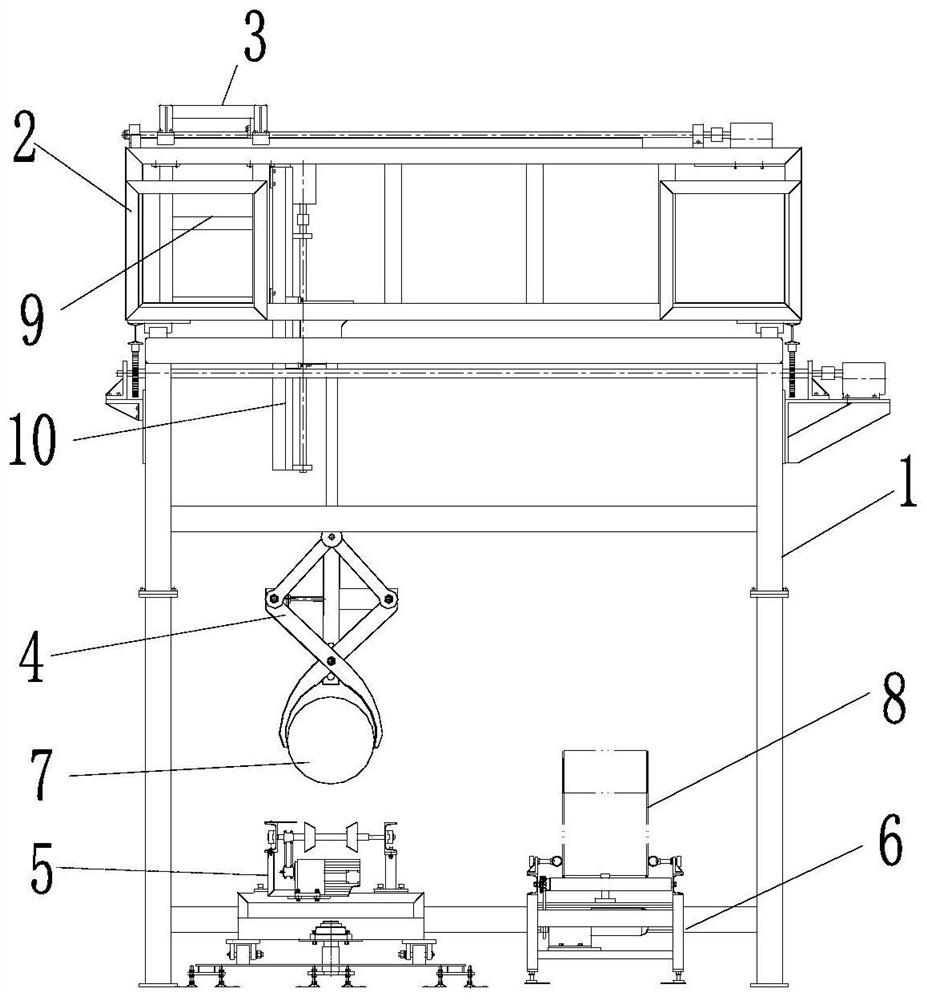

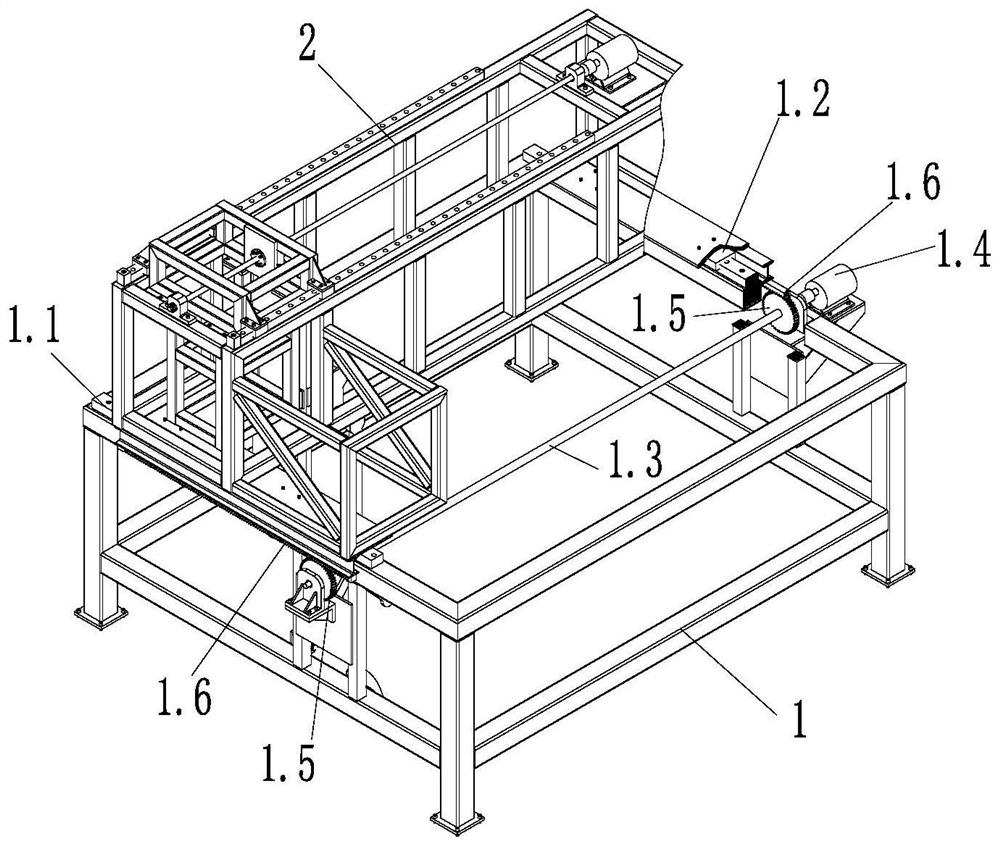

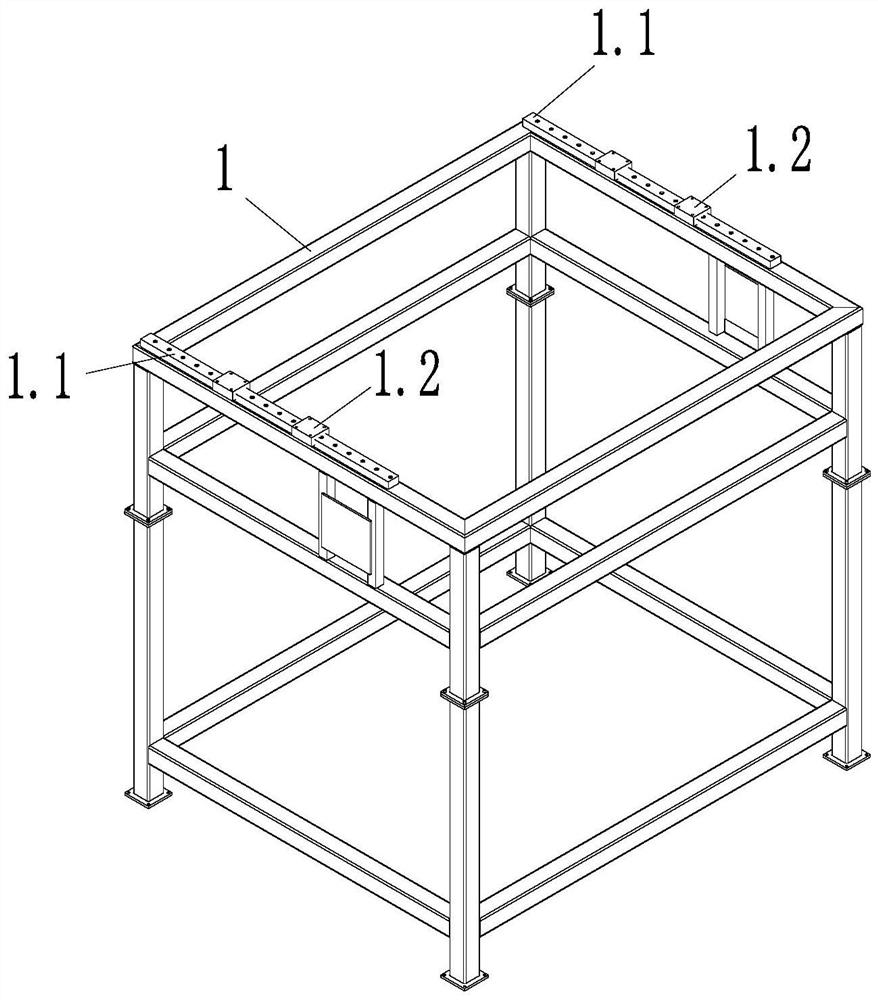

[0055] like figure 1 The boxing device for a steel hoop winding gas cylinder shown includes a gantry frame 1, a horizontal moving frame 2, a sliding seat 3, a handle mechanism 4, a turntable mechanism 5, and a conveying mechanism 6; the horizontal moving frame 2 is arranged on The top of the gantry 1 can move relative to it along the X direction, the sliding seat 3 is set on the horizontal shift frame 2 and can move relative to it along the Y direction, the gripper mechanism 4 is set under the sliding seat 3 and can move relative to it along the Z direction, and the turntable mechanism 5 is set on one side under the gantry 1 for installing and rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com