Automatic loading system and application thereof

An automatic and stacking device technology, applied in the field of automatic loading equipment, can solve the problems of large secondary dust and easy rotten bags, and achieve the effect of avoiding secondary dust and rotten bags

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

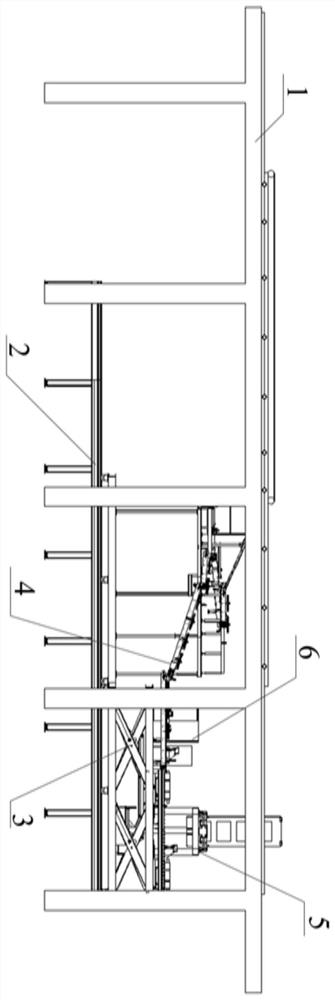

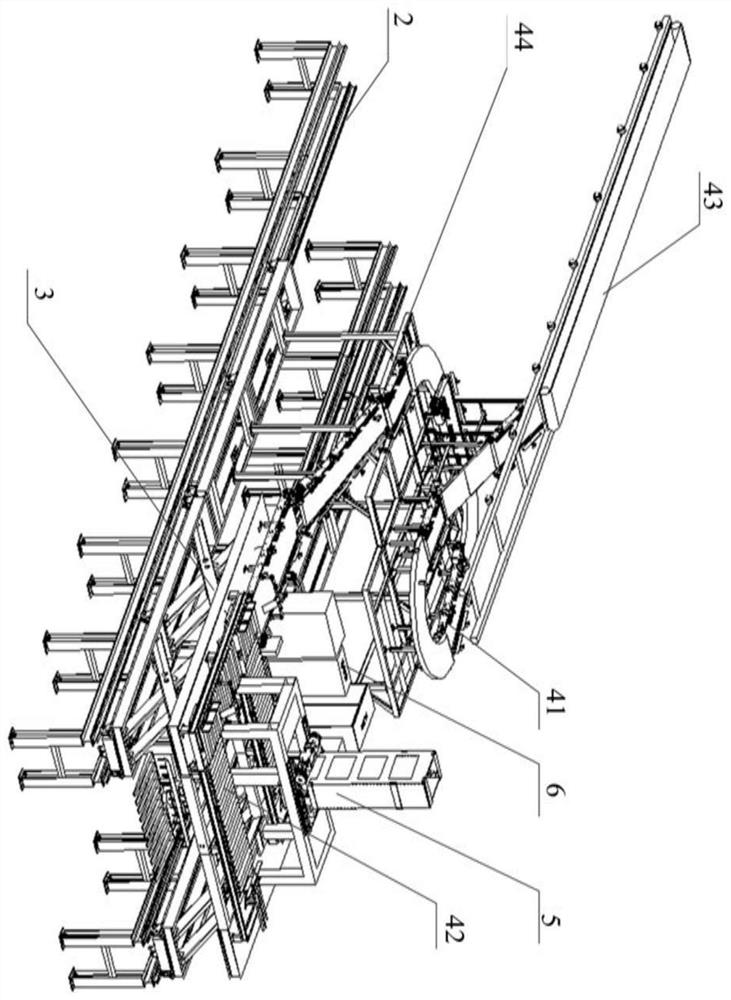

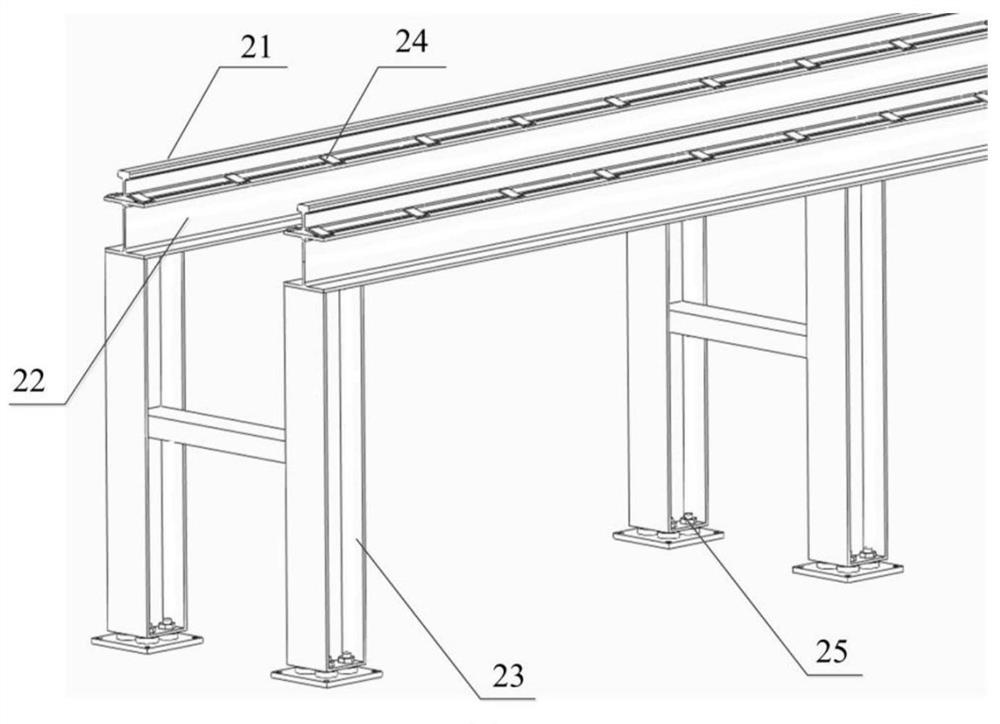

[0061] Such as Figure 1-Figure 13 As shown, the automatic loading system includes a support guide rail 2, a mobile lifting platform 3, a conveying and stacking device 4 and a lifting and stacking device 5;

[0062] The mobile lifting platform 3 is installed on the support rail 2, and can move on the supporting guide rail 2; the mobile lifting platform 3 includes a lifting platform 31 and a moving bracket 32, and the bottom of the lifting platform 31 is symmetrically arranged with two The mobile bracket 32, the two mobile brackets 32 are respectively slidably arranged on the two supporting guide rails 2;

[0063] The conveying and stacking device 4 and the lifting and stacking device 5 are all installed on the mobile lifting platform 3;

[0064] The conveying and stacking device 4 includes a conveying section and a lifting section 42 of the conveying and stacking device. The input end of the conveying section cooperates with the loading roadway 1, and the conveying section tr...

Embodiment 2

[0093] Such as Figure 1-Figure 13 As shown, this embodiment is based on Embodiment 1, and also includes a vehicle information detection device 7;

[0094] The vehicle information detection device 7 includes a mounting bracket 71, a vehicle detection linear module 72, a laser ranging sensor 73 and an adapter plate 74;

[0095] The mounting bracket 71 is installed on the lifting platform 31, the adapter plate 74 is installed on the mounting bracket 71, the vehicle detection linear module 72 is installed on the adapter plate 74, and the laser ranging sensor 73 is installed on the vehicle detection On the linear module 72.

[0096] In this embodiment, the vehicle information detection device 7 is used to detect the offset of the vehicle, the size of the trunk, and the like. When the vehicle stops, the lifting platform 31 descends to the top of the railings on both sides of the carriage according to the feedback signal from the touch sensing device 314, and the vehicle detection...

Embodiment 3

[0098] Such as Figure 1-Figure 13 As shown, this embodiment is based on embodiment 1, and the difference with embodiment 1 is:

[0099] The bag pushing mechanism 424 adopts a gantry structure, and the bag pushing cylinder is installed above the conveyor, thereby canceling the jacking mechanism and simplifying the overall structure. The roller conveyor 422 is replaced by a belt conveyor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com