High-heat-sealing and high-light-transmittance glass film and preparation method thereof

A high light transmittance, glass film technology, applied in the direction of film/sheet adhesives, adhesives, etc., can solve the problems of uneven film quality, poor heat sealing, poor light transmittance, etc., and achieve simple and mature production technology , Improve transparency, improve the effect of heat sealability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

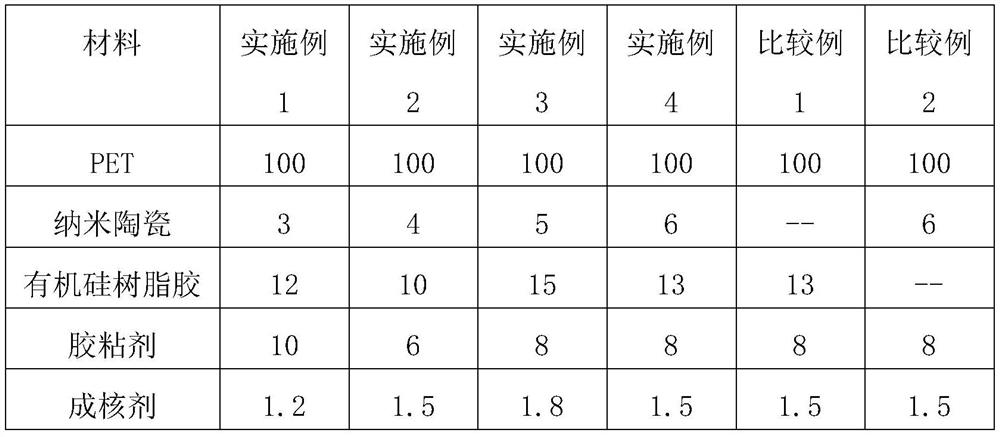

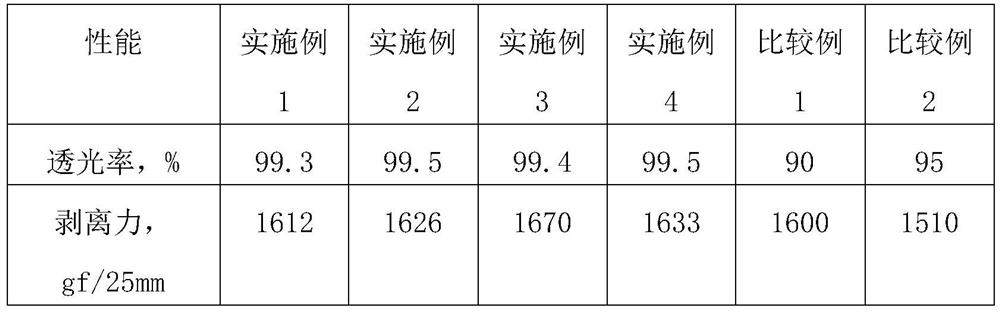

[0014] Table 1 below shows the proportions of the examples and comparative examples to prepare glass films. The difference between the embodiment and the comparative example is that the comparative example 1 removes the nano-ceramics on the basis of the embodiment 4; the comparative example 2 removes the silicone resin glue on the basis of the embodiment 4.

[0015] In the embodiment, the adhesive is phenolic-polyvinyl acetal resin; the particle size of the nano-ceramics is in the range of 10-50nm; the nucleating agent is NC-4 from Toye Corporation of Japan.

[0016] Examples of the present invention and comparative examples are shown in Table 1.

[0017] Table 1

[0018]

[0019] The preparation method of the above embodiment high heat sealing high light transmittance glass film is as follows:

[0020] (1) Weigh each material in proportion, put it into a high-speed mixer and mix evenly, the mixing time is 5 minutes, the mixing speed is 800 rpm, and then the material is r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| haze | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com