A method for reducing bending damage of pipe piles in soft soil

A technology of bending failure and pipe piles, applied in soil protection, sheet pile walls, buildings, etc., can solve the problems of poor lateral bearing capacity of a single pipe pile, weak bearing pressure of pipe piles, and weak lateral stiffness, etc., to achieve Improve bearing capacity, improve efficiency, and reduce the effect of bending damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

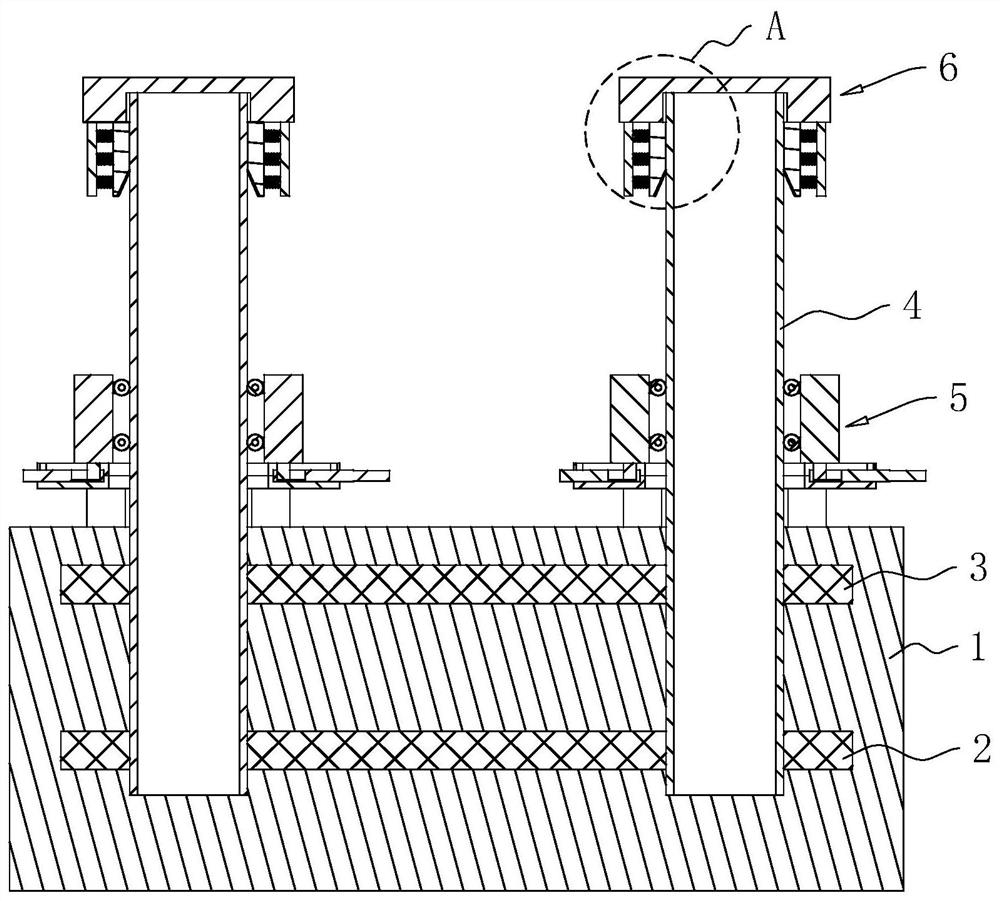

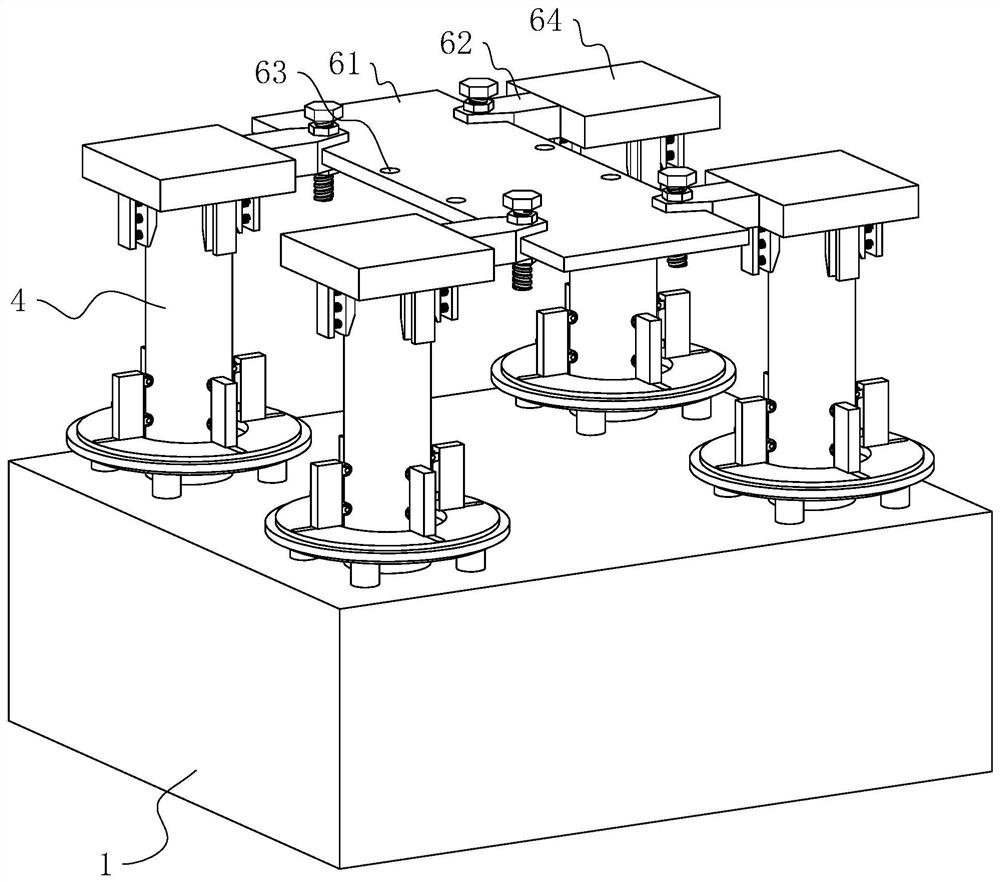

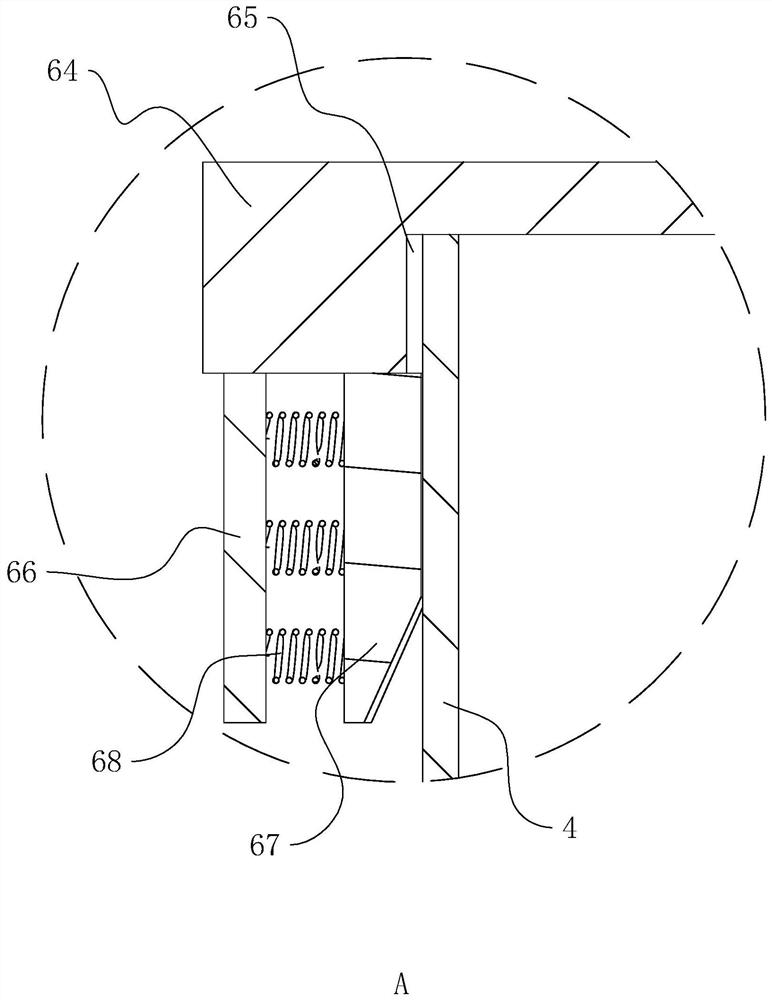

[0042] Attached to the following Figure 1-4 This application will be described in further detail.

[0043] The embodiments of the present application disclose a method for reducing bending damage of pipe piles in soft soil. refer to figure 1 , the method for reducing the bending damage of pipe piles in soft soil includes the following steps:

[0044] step1: Survey and inspection of soil layer 1 of the construction site. The inspection and inspection can be carried out by means of drilling.

[0045] step2: Set the first layer of reinforcement layer 2 at the position of the design elevation.

[0046] step3: Set the second reinforcement layer 3 at the position of the design elevation, and the second reinforcement layer is located above the first reinforcement layer.

[0047] The materials used for the first layer of reinforcement layer 2 and the second layer of reinforcement layer 3 are both concrete, and both the first layer of reinforcement layer 2 and the second layer of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com