Power transmission line tower structure for goaf

A technology for transmission lines and goafs, applied in infrastructure engineering, towers, building types, etc., can solve problems such as difficulty in implementing deviation correction, foundation settlement and deformation, and unstable foundations in goafs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

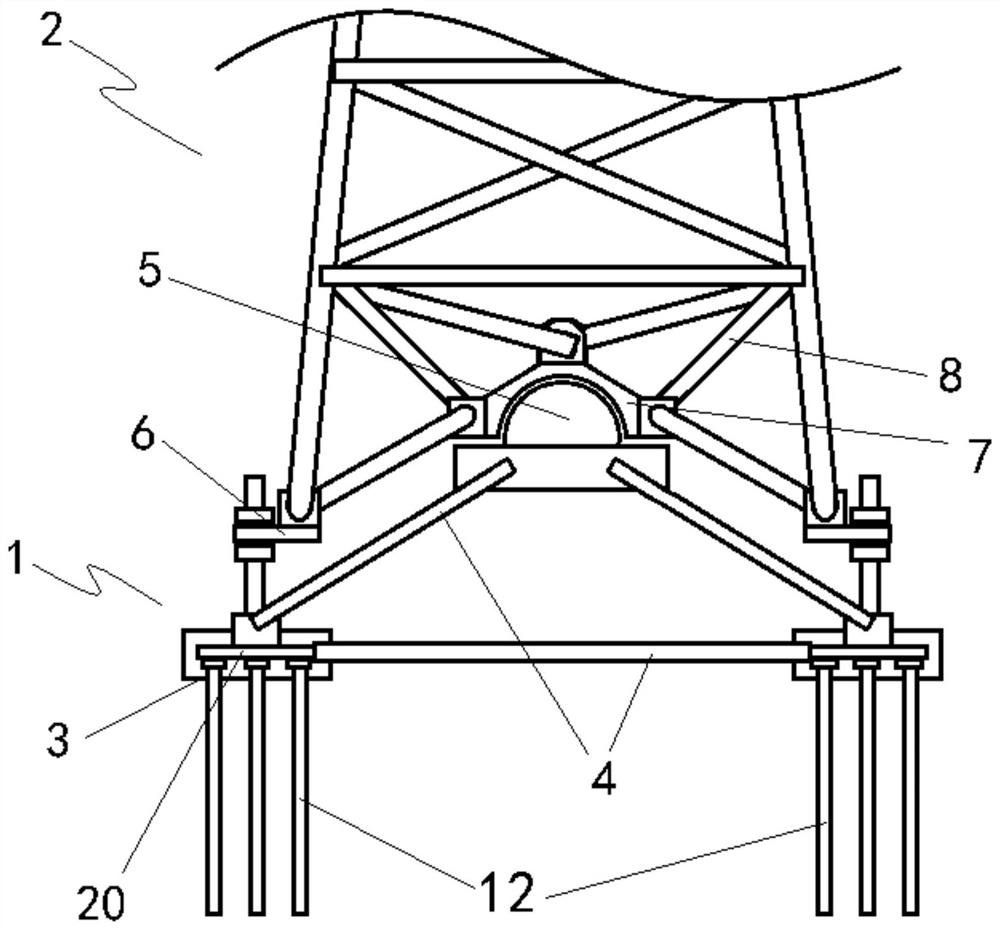

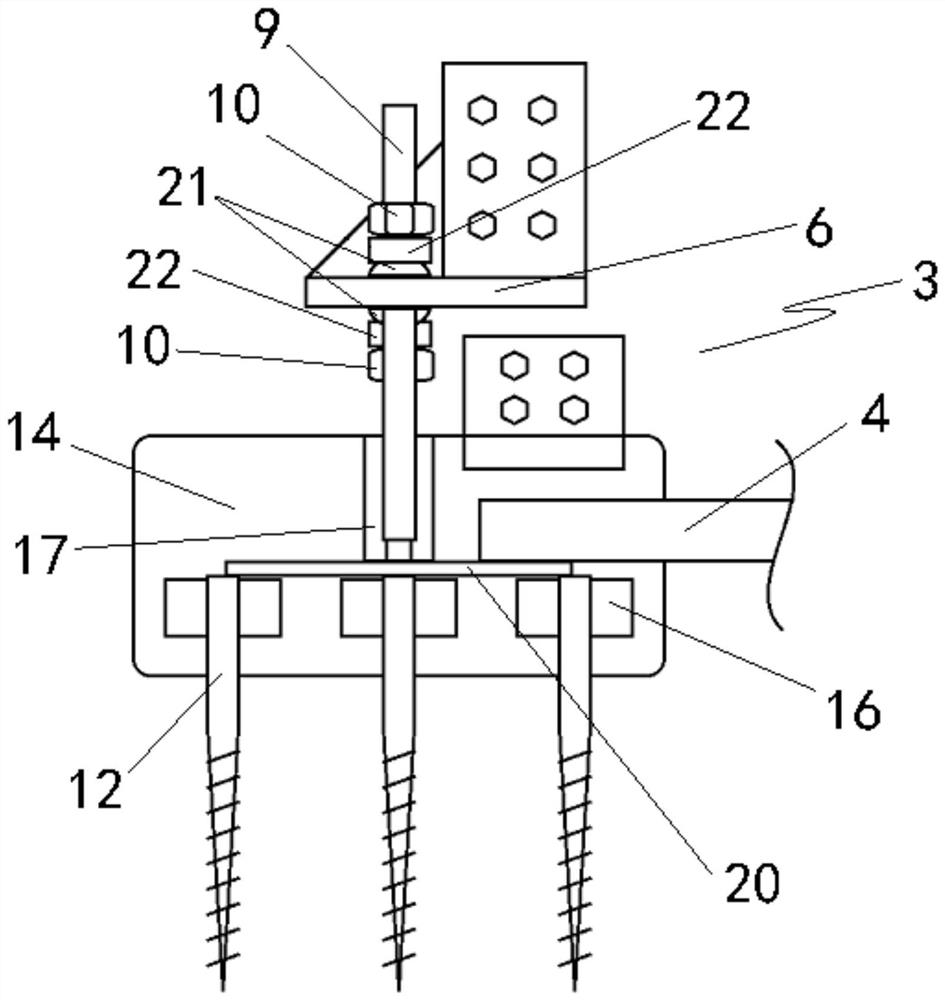

[0017] according to figure 1 , figure 2 , image 3 As shown, a power transmission line tower structure for gobs includes a tower base 1 and a tower body 2 connected to the tower base 1, and the tower base 1 includes a plurality of bases arranged in a rectangular array 3, and the ball joint 5 fixedly arranged above the tower foundation 1 through the bottom bracket 4; the bottom of the tower body 2 is provided with an adjusting foot plate 6 corresponding to each of the bases 3, and the center of the bottom of the tower body 2 The upper bracket 8 is fixed with the ball bowl 7 that cooperates with the ball joint 5; each of the abutments 3 is respectively provided with an adjustment screw 9 extending vertically upward, and each of the adjustment feet 6 passes through the adjustment hole Cooperate with the adjusting stud 9 and fix it by double nuts 10.

[0018] In the above setting, the tower base 1 bears the main weight of the tower body 2 through the cooperation of the ball jo...

Embodiment 2

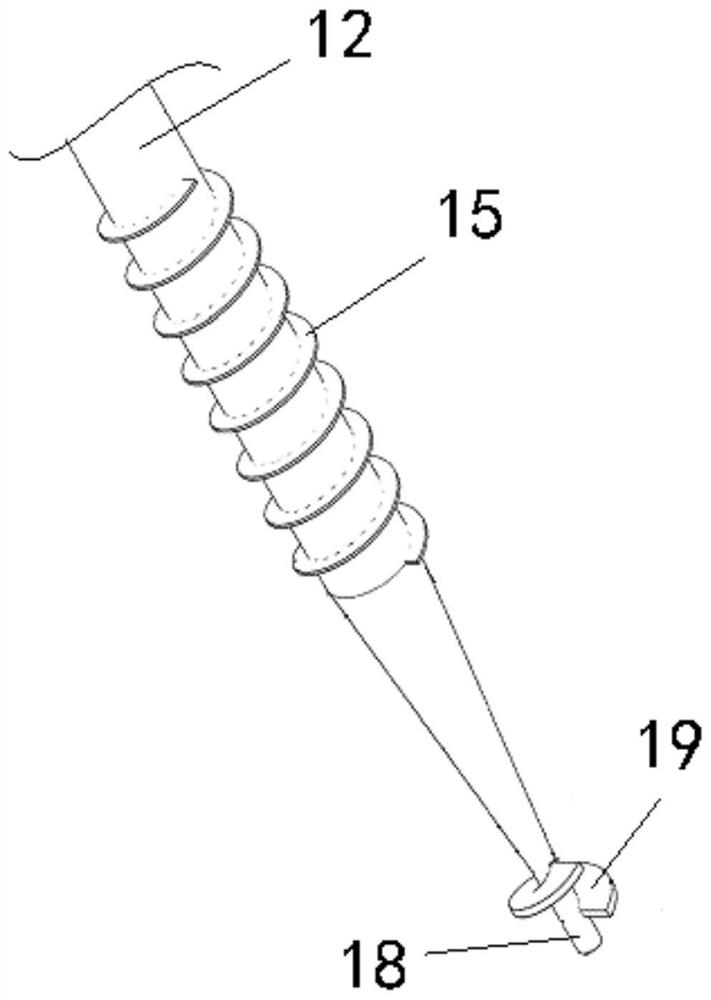

[0020] Each of the abutments 3 is composed of a foundation pile 12 and a concrete pouring body 14; the foundation pile 12 is a pointed cone structure with a plurality of tips inserted into the ground, and the conical surfaces of each of the foundation piles 12 are concentric. A first helical blade 15 is provided, the outer diameter of the first helical blade 15 is equal to the outer diameter of the large end of the foundation pile 12, and the large ends of each of the foundation piles 12 are also radially connected with a plurality of fins 16 ; the concrete pouring body 14 is a solid structure solidified and connected to the top of each foundation pile 12 , and the adjusting stud 9 is fixedly arranged on the top of the concrete pouring body 14 . The tip of the foundation pile 12 is provided with an axially extending positioning shaft 18; the outer wall of the positioning shaft 18 is provided with a second helical blade 19, and the pitch of the second helical blade 19 is greater...

Embodiment 3

[0023] It also includes a connecting screw sleeve 17, which is prefabricated longitudinally in the center of the concrete pouring body 14, and the top end of the connecting screw sleeve 17 is flush with the installation surface of the concrete pouring body 14, and the adjusting stud The bottom of 9 is threadedly engaged with the connecting screw sleeve 17. In this setting, the adjusting screw 9 cooperates with the connecting screw sleeve 17, which not only ensures the reliability of the connection between the adjusting screw sleeve 17 and the concrete pouring body 14, but also facilitates maintenance and updating of the adjusting screw 9 later.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com