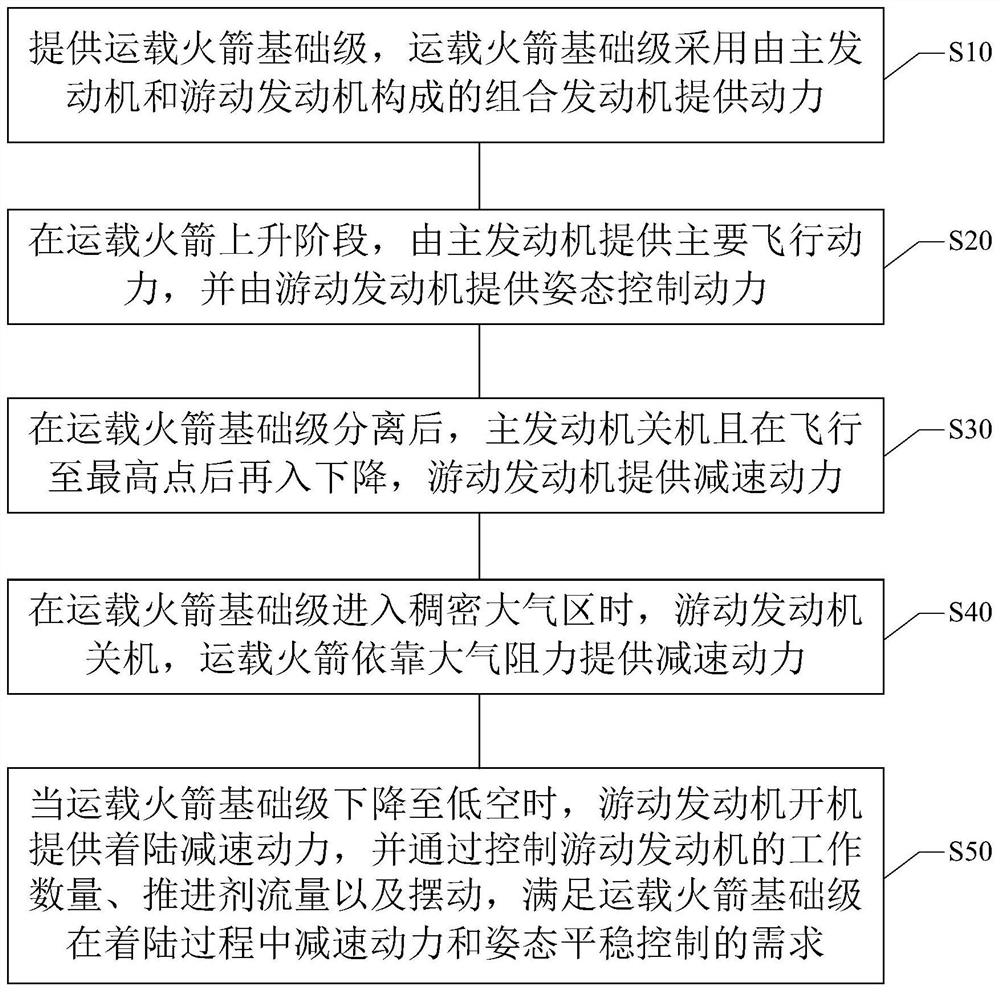

Vertical recovery method for carrier rocket base stage by using vernier engines

A technology for launch vehicles and recovery methods, which is applied to machines/engines, rocket engine devices, mechanical equipment, etc., can solve problems such as difficulty, complex design, and inability to guarantee reliability, achieve wide application, avoid deep throttling, and achieve convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

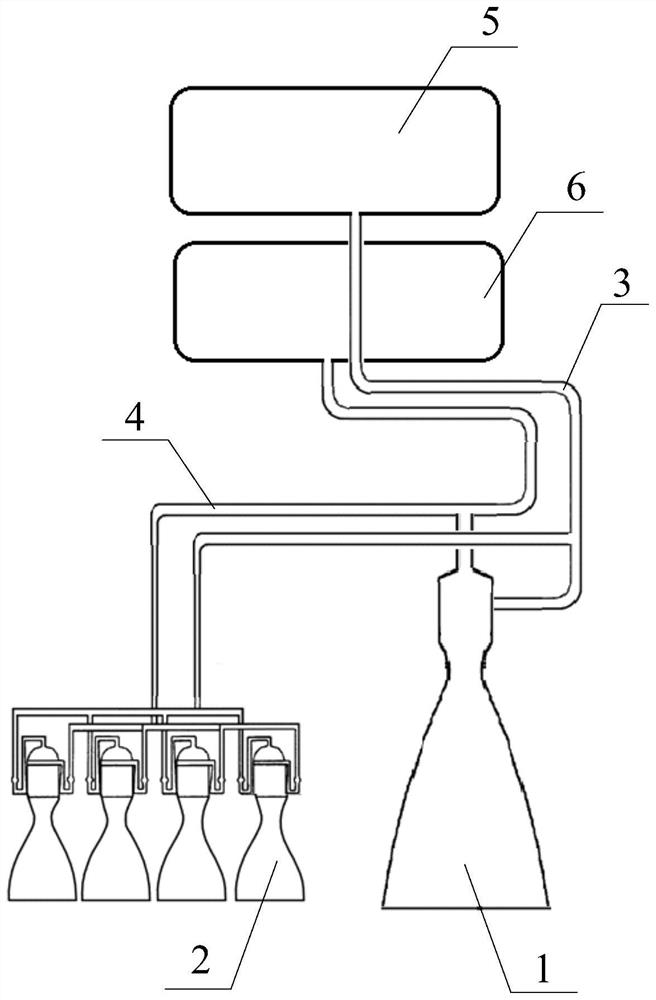

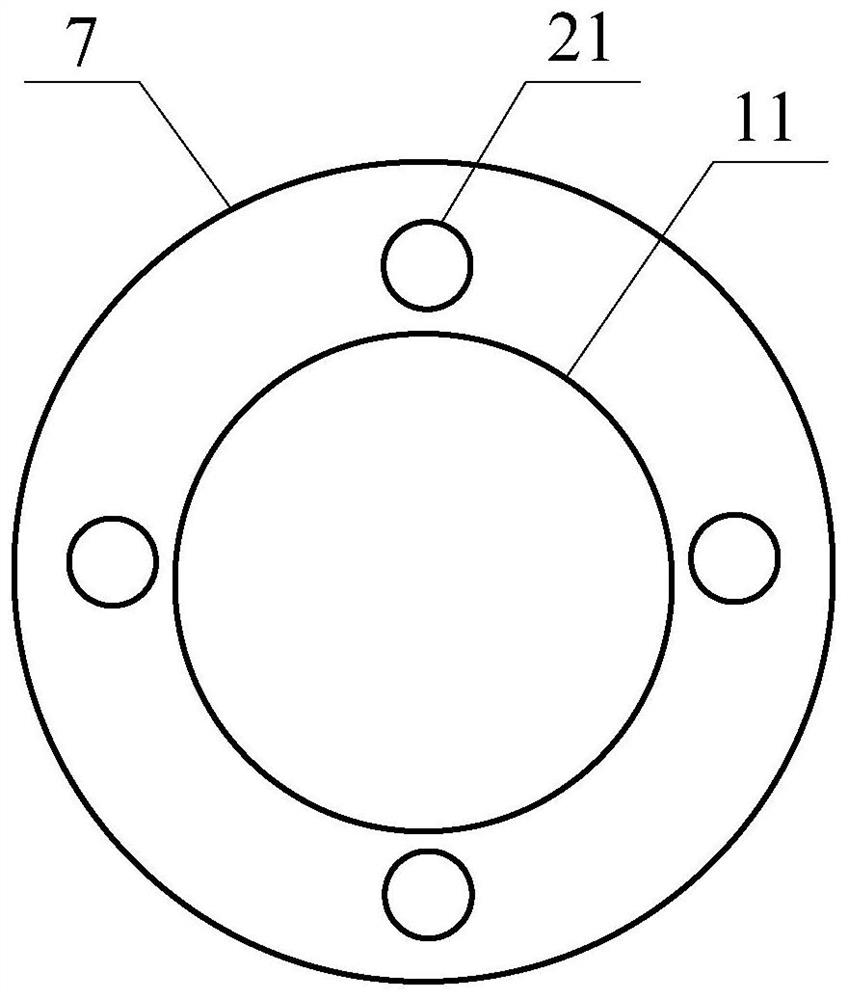

Embodiment 1

[0047] The basic stage of the launch vehicle is equipped with a main engine 1 and four swimming engines 2, in which liquid oxygen is used as the oxidant, and kerosene is used as the combustion agent; the main engine 1 is equipped with a main engine nozzle 11, and the thrust at sea level is 300 tons. Oxygen-enriched supplementary combustion cycle is adopted; each traveling engine 2 is equipped with a traveling engine nozzle 21, and the sea level thrust of each traveling engine 2 is 10 tons, and the diameter of the basic stage of the launch vehicle can be 3.35 meters. The structural mass (including the engine) is 20 tons; the layout of the main engine nozzle 11 and the swimming engine nozzle 21 is as follows: image 3 structure shown.

Embodiment 2

[0049] The basic stage of the launch vehicle is equipped with a main engine 1 and four swimming engines 2, in which liquid oxygen is used as the oxidant, and liquid hydrogen is used as the combustion agent; the main engine 1 is equipped with a main engine nozzle 11, and the thrust at sea level is 300 tons , using a supplementary combustion cycle; each traveling engine 2 is equipped with a traveling engine nozzle 21, the sea level thrust of each traveling engine 2 is 15 tons, the diameter of the basic stage of the launch vehicle can be 5 meters, and the structural quality of the basic stage is (including the engine) is 30 tons; the layout of the main engine nozzle 11 and the swimming engine nozzle 21 is as follows: image 3 structure shown.

Embodiment 3

[0051] The basic stage of the launch vehicle is equipped with a main engine 1 and six swimming engines 2, in which liquid oxygen is used as the oxidant, and kerosene is used as the combustion agent; the main engine 1 is equipped with a main engine nozzle 11, and the thrust at sea level is 300 tons. Oxygen-enriched supplementary combustion cycle is adopted; each traveling engine 2 is equipped with a traveling engine nozzle 21, the sea level thrust of each traveling engine 2 is 8 tons, the diameter of the base stage of the launch vehicle is 3.8 meters, and the structural quality of the base stage is (including the engine) is 25 tons; the layout of the main engine nozzle 11 and the swimming engine nozzle 21 is as follows: Figure 4 structure shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com