Pressure-stabilizing and constant-flow control system and method for LNG multi-immersed-pump marine filling sledge

A technology of constant flow control and submersible pump, which is applied in the pipeline system, container filling method, container discharge method, etc., can solve the problems of large measurement error of back-end flowmeter and unbalanced outlet pressure, and achieves the guarantee of safety, The effect of improving filling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

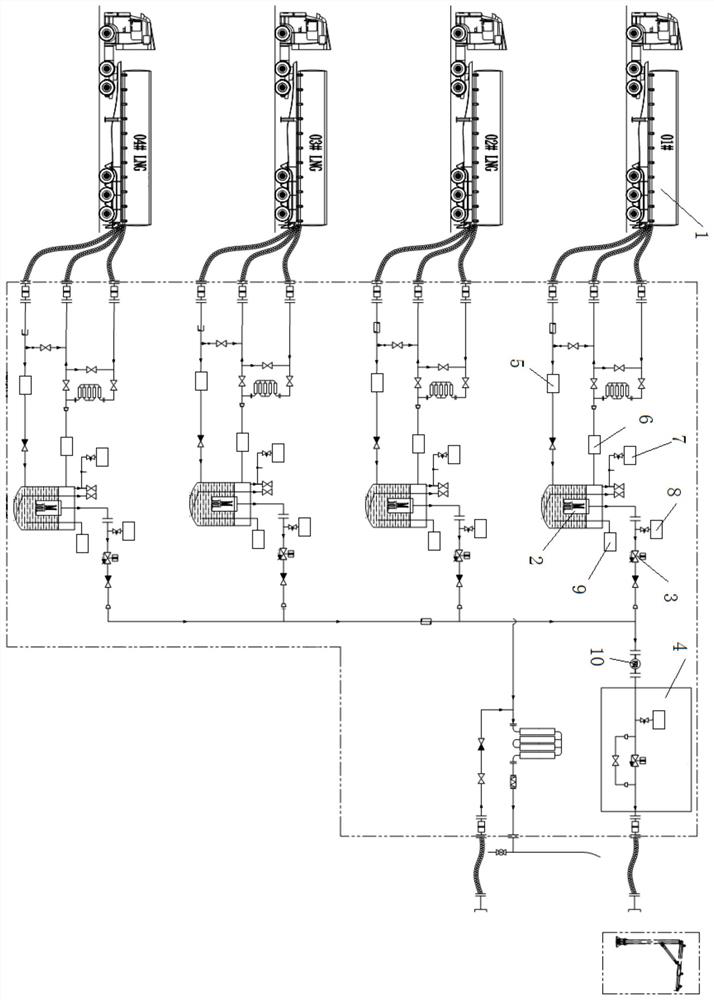

[0034] Such as Figure 1~2 As shown, a LNG multi-submersible pump marine filling skid regulator constant current control system, including station control system, tank 1, submersible pump 2, filling valve 3 and metering system 4; the submersible pump 2 They are separately communicated with the tank 1 to form a plurality of independent filling pipelines, and the multiple independent filling pipelines are confluent at the metering system 4, and the station control system is connected with the submersible pump 2 respectively, and the station control system The control system controls the output pressure of the submersible pump 2 respectively, so that the pressures at the confluence of each filling pipeline are balanced; On-off control of the road.

[0035] A liquid inlet valve 5 and an air return valve 6 are arranged between the submersible pump 2 and the tank 1. The submersible pump is also equipped with a frequency converter, and the submersible pump is completed through the l...

Embodiment 2

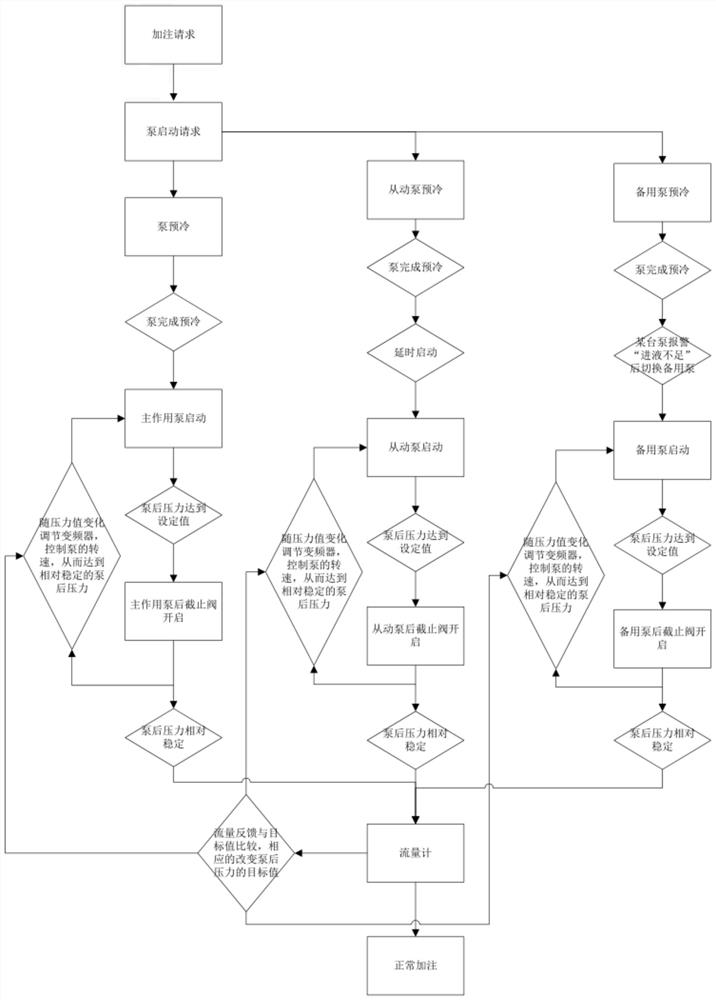

[0045] This embodiment provides a method for controlling constant pressure and constant flow of LNG multi-submersible pump 2 marine filling skids; this embodiment takes four submersible pumps 2 as an embodiment;

[0046] First, select one of the four submersible pumps 2 as the standby pump through the station control system, and then select the other one as the priority pump, and turn on all the submersible pumps 2 to enable the entire system to enter the automatic state. At this time, The PLC controls to open the liquid inlet valve 5 and the air return valve 6 of each submersible pump 2, and fill the LNG in the tank 1 into the submersible pump 2, so that each submersible pump 2 enters a pre-cooling state, and is ready for filling;

[0047] The LNG filling metering system 4 sends a filling request to the PLC, and the PLC detects the temperature of the pump pool through the temperature detection components 9 of each submersible pump 2, and judges whether the precooling of the pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com