Self-adaptive hot pressing mechanism

A heat-pressing mechanism and self-adaptive technology, which is applied in the direction of presses, battery assembly machines, and final product manufacturing, can solve problems such as parallelism errors, hot-pressing head bonding, and quality degradation of hot-pressing sizing, so as to eliminate parallelism error, quality-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing:

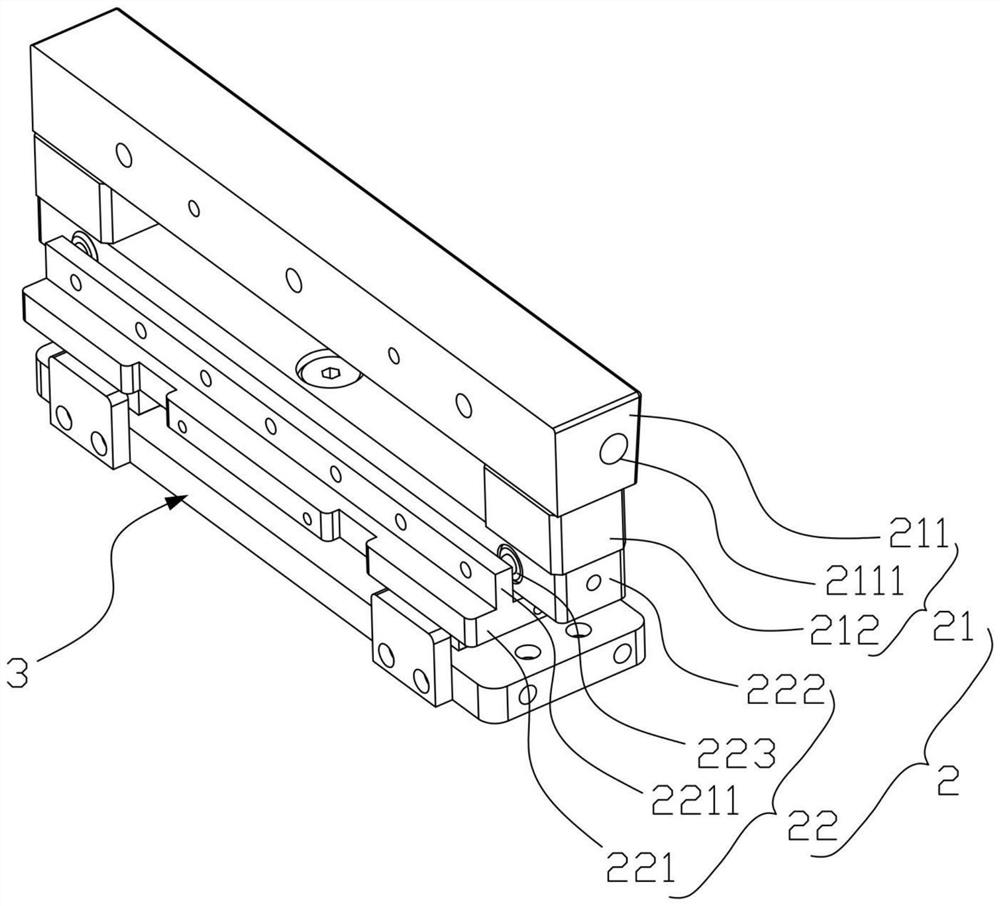

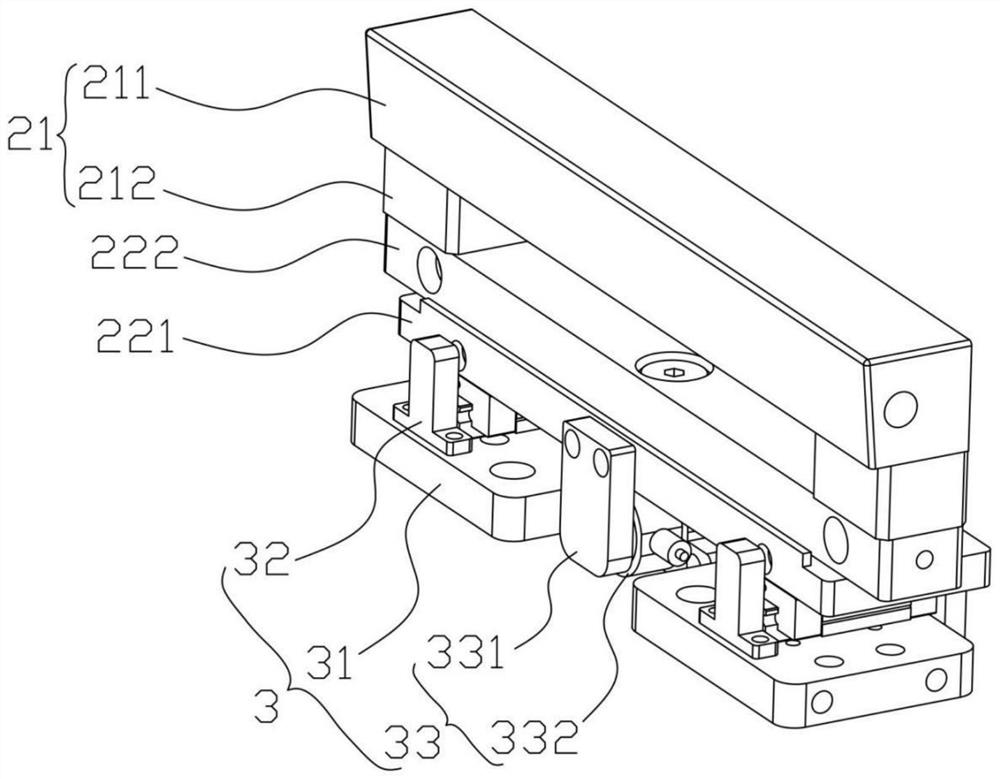

[0023] Please refer to figure 1 with figure 2 , an adaptive heat-pressing mechanism, including an opening and closing drive assembly 1 and a heat-pressing arm assembly 2, the heat-pressing arm assembly 2 is set in two groups, and the two sets of heat-pressing arm assemblies 2 are symmetrically arranged on the opening and closing drive assembly 1, and the opening and closing The driving assembly 1 drives two sets of thermal pressing arm assemblies 2 to move toward or backward. The thermal pressing arm assembly 2 includes a thermal pressing head 21 and a parallelism adaptive module 22. The thermal pressing head 21 is installed on the parallelism adaptive module 22. When different forces are applied to both sides of the heat-pressing surface of the heat-pressing head 21 in the longitudinal direction, the parallelism adaptive module 22 makes the heat-pressing head 21 elastic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com