Self-adaptive rolling folding mechanism

A self-adaptive, roller technology, applied in applications, household components, household appliances, etc., can solve the problems of reduced work efficiency, slow action, easy fatigue, etc., to achieve high work efficiency, good folding quality, and labor-saving effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing:

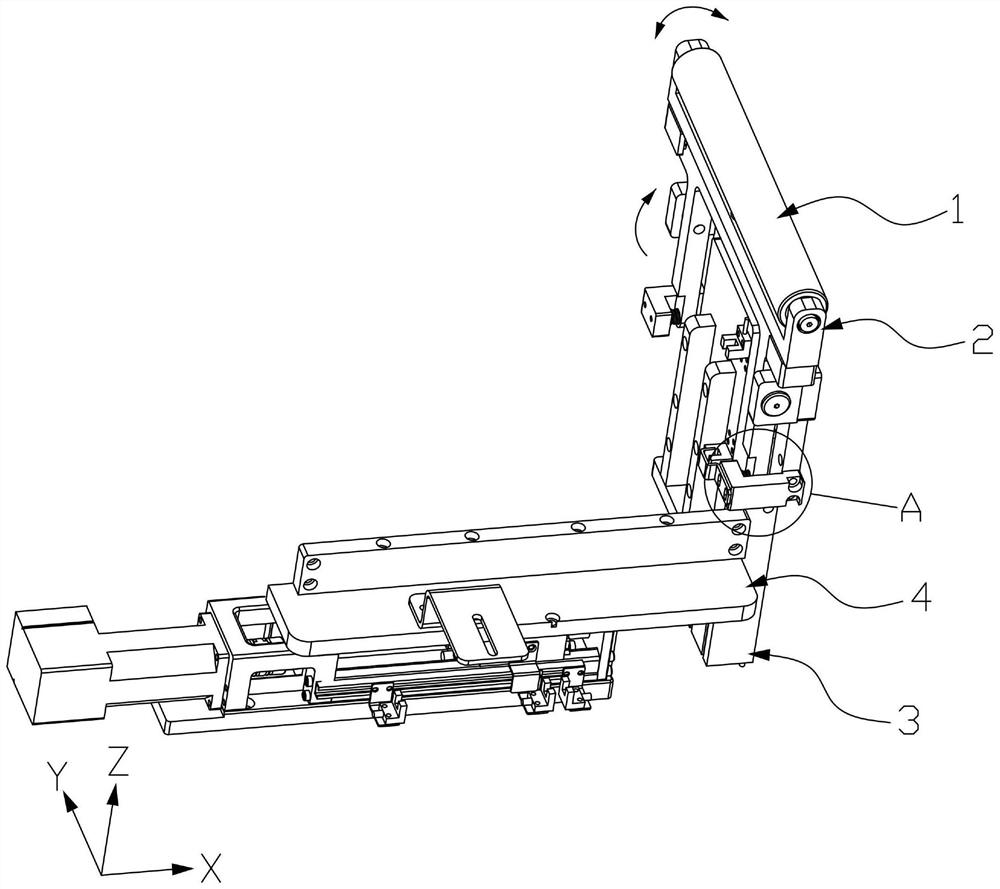

[0027] Please refer to figure 1 , an adaptive rolling mechanism, including a roller 1, a parallelism self-adaptive pressing assembly 2 and a lifting drive assembly 3, the roller 1 is rotatably connected to the parallelism self-adapting springing assembly 2, and the parallelism self-adapting springing assembly 2 is installed on On the lifting drive assembly 3 , the lifting drive assembly 3 drives the parallelism self-adaptive spring pressing assembly 2 to drive the drum 1 to perform lifting movement.

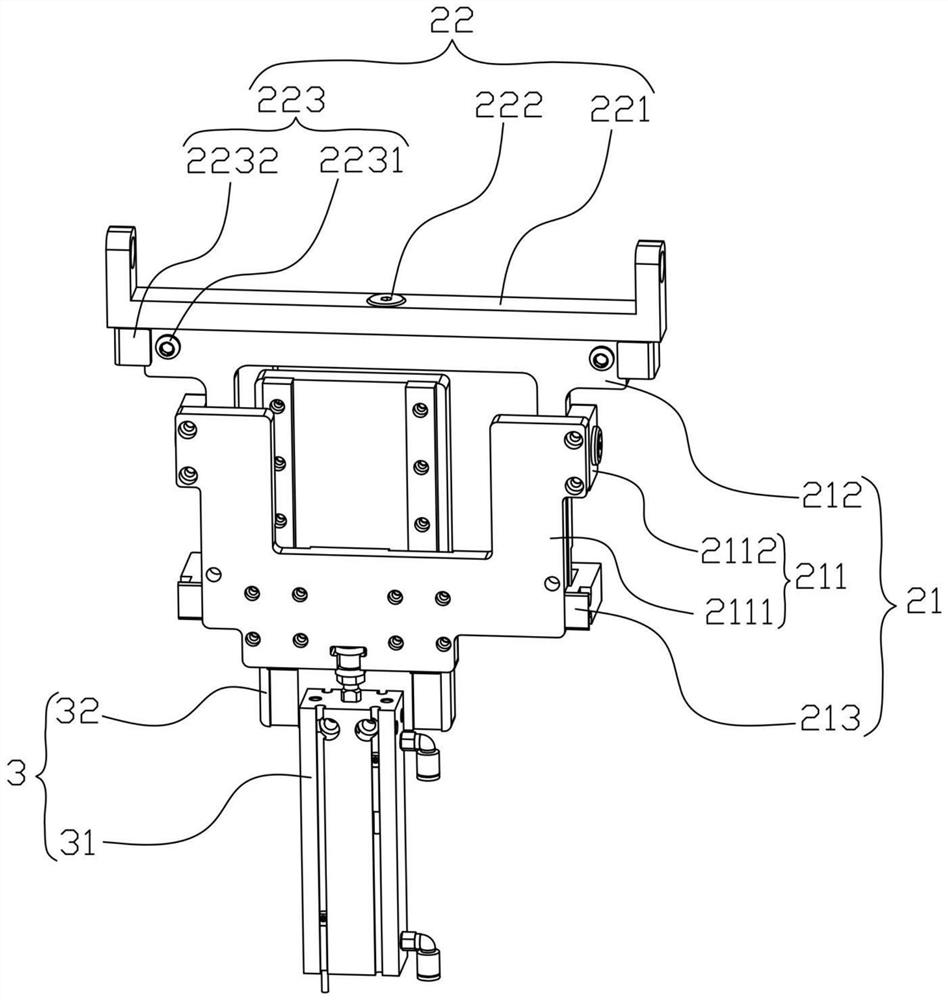

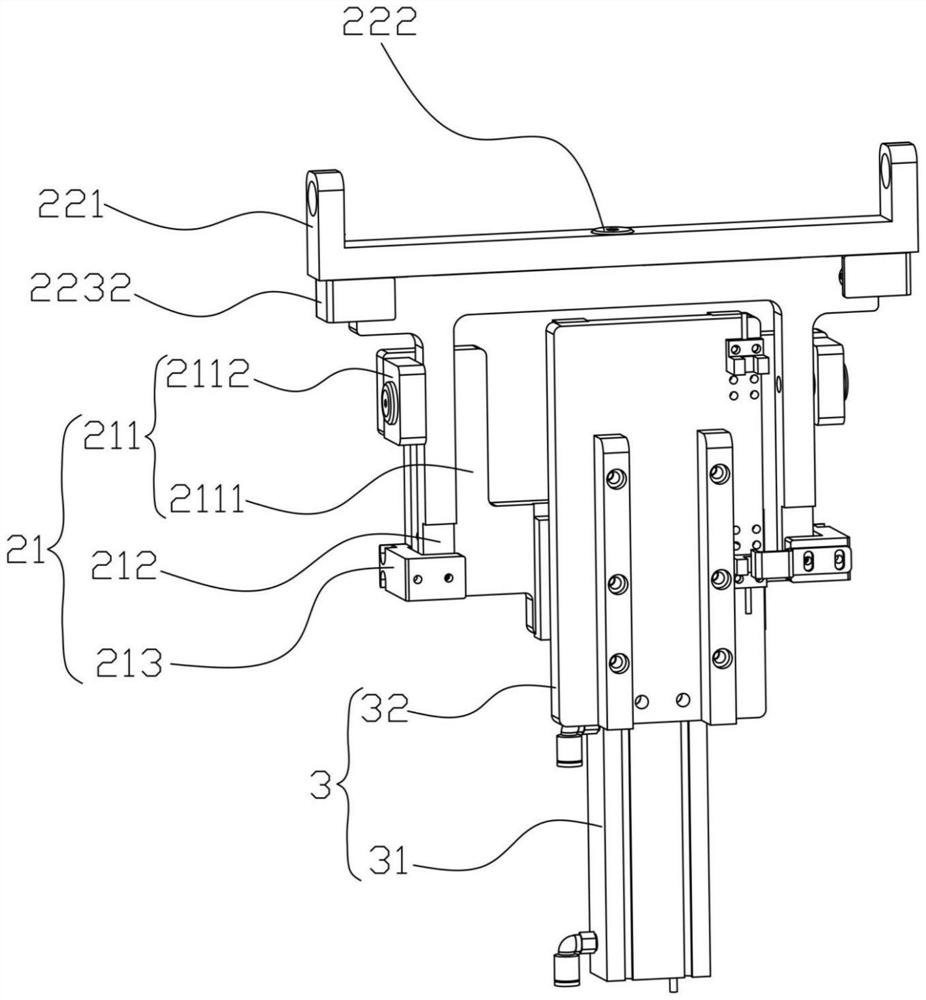

[0028] Please refer to figure 1 and figure 2 , the parallelism self-adaptive spring pressing assembly 2 includes an elastic flip reset module 21 and an elastic rotation reset module 22, the elastic flip reset module 21 is installed on the lifting drive assembly 3, the elastic rotation reset module 22 is installed on the elastic flip reset module 21, and the drum 1 It is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com