Steam turbine generator stator end nose end loosening treatment process method

A steam turbine generator and stator end technology, which is used in the manufacture of motor generators, electric components, electromechanical devices, etc., can solve the problems of loose ends of stator coils, and achieve the effect of reducing the repair workload and shortening the repair period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

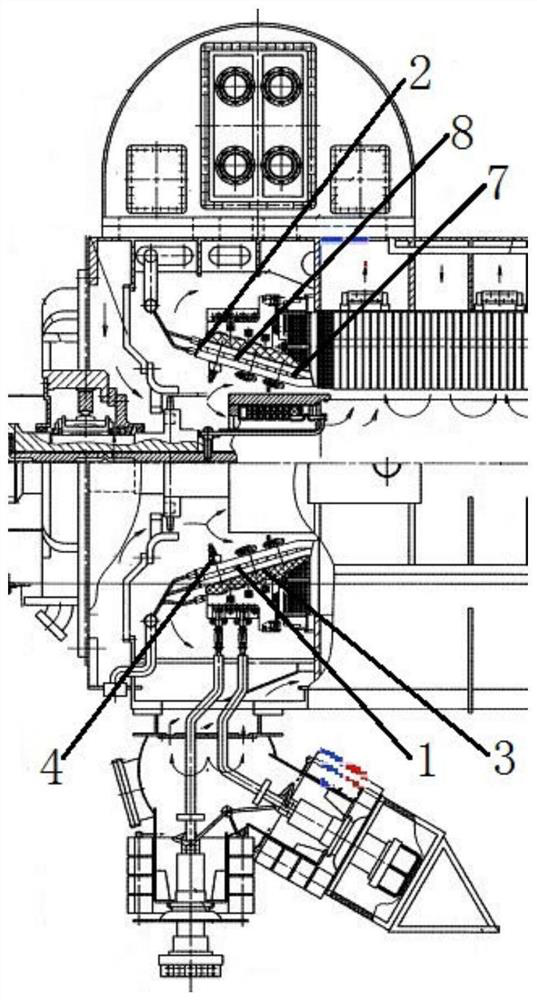

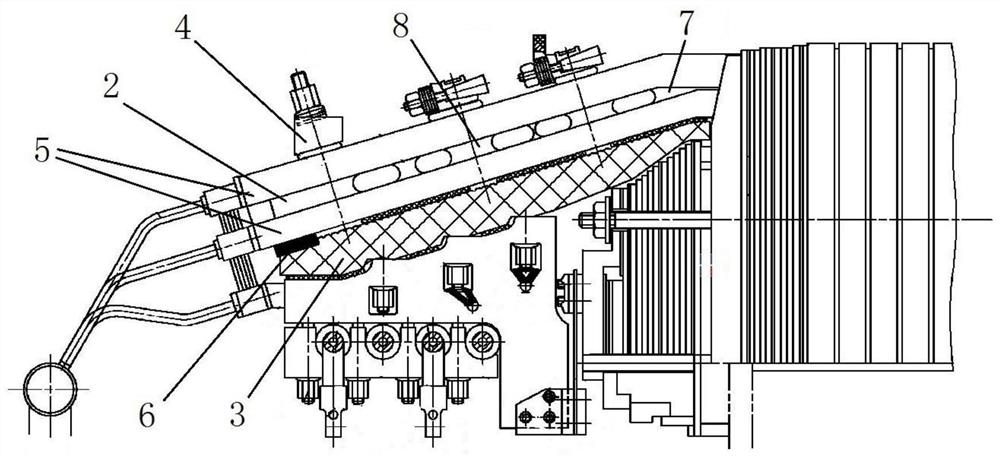

[0024] 1) if figure 1 with figure 2 As shown, a comprehensive inspection of the stator end 1 is carried out, and it is determined that the notch area 7 and the involute area 8 of the stator end 1 are not loose, including between the stator coil 5 and the insulating cone ring 3, between the stator coil 5 itself, and the stator Between the coil 5 and the insulating fixing ring 4, it is determined that only the nose end 2 is loose, including the nose end conformable material 6 between the stator coil 5 nose end 2 and the insulating cone ring 3, and between the stator coil 5 and the insulating fixing ring 4 ;

[0025] 2) if figure 2 As shown, remove the insulating fixing ring 4 that fixes the inner diameter position of the stator coil 5 nose end 2, and remove the conformable material between the fixed stator coil 5 nose end 2 outer diameter po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com