An implantable flexible magnetic response artificial bladder substrate and its manufacturing method

An artificial bladder and magnetic matrix technology, applied in the field of biomedicine, can solve the problems of limited hydraulic pressure, human muscle level is far apart, lack of realistic medical design and biological safety, etc., to achieve good biocompatibility, high modulus , high density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

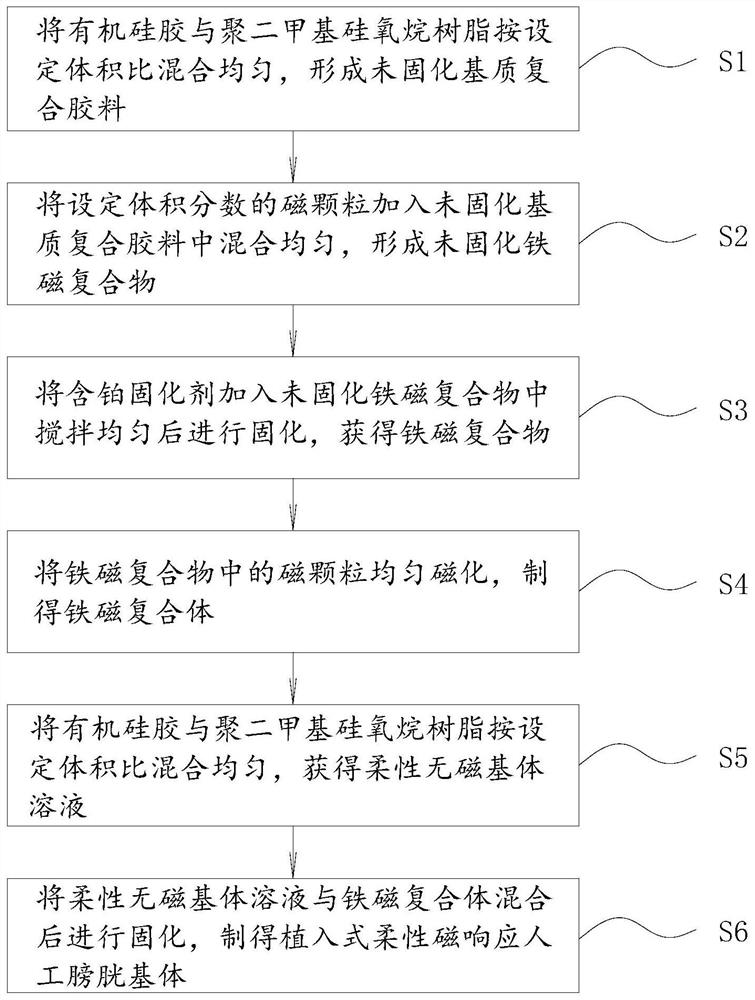

Method used

Image

Examples

Embodiment 1

[0048] The uncured matrix was first prepared by uniformly mixing two silicone-based materials, Ecoflex 00-30 (Smooth-on Inc) with PDMS resin (Sylgard 184, Dow Corning) in a volume ratio of 5:1 using a planetary mixer The compound rubber was kept at 800rpm for 2min, and the foam was removed for 1min. For Ecoflex 00-30 components, the volume ratio of Parts A and B is 1:1.

[0049] The NdFeB particles with a volume fraction of 25% and an average particle size of 5 μm were uniformly mixed with the uncured matrix compound compound for 2 min on a 10-speed gear by a vibrating mixer, and the uncured ferromagnetic composite was prepared by defoaming for 1 min.

[0050] 5.5 wt % of platinum-containing curing agent was added to the uncured ferromagnetic composite, and the curing agent was stirred evenly, and the above operation was completed within 30 minutes. The ferromagnetic composite was obtained by curing at 40 °C for 4 h. The magnetic particles in the ferromagnetic composite are ...

Embodiment 2

[0055] The uncured matrix was first prepared by uniformly mixing two silicone based materials, Ecoflex 00-30 (Smooth-on Inc) with PDMS resin (Sylgard 184, Dow Corning) in a volume ratio of 6:1 using a planetary mixer The compound rubber was kept at 800rpm for 3min, and defoamed for 1min. For Ecoflex 00-30 components, the volume ratio of Parts A and B is 1:1.

[0056] The NdFeB particles with a volume fraction of 30% and an average particle size of 5 μm were uniformly mixed with the uncured matrix composite compound for 4 min on a 10-speed gear by a vibrating mixer, and the uncured ferromagnetic composite was prepared by defoaming for 1 min.

[0057] 7.85wt% of platinum-containing curing agent was added to the uncured ferromagnetic composite, and the curing agent was stirred evenly, and the above operation was completed within 30 minutes. The ferromagnetic composite was obtained by curing at 40 °C for 10 h. The magnetic particles in the ferromagnetic composite are uniformly m...

Embodiment 3

[0062] The uncured matrix was first prepared by uniformly mixing two silicone based materials, Ecoflex 00-30 (Smooth-on Inc) with PDMS resin (Sylgard 184, Dow Corning) in a volume ratio of 9:1 using a planetary mixer For compound rubber, the speed was 1200rpm for 3min, and the foam was removed for 1min. For Ecoflex 00-30 components, the volume ratio of Parts A and B is 1:1.

[0063] The NdFeB particles with a volume fraction of 40% and an average particle size of 5 μm were uniformly mixed with the uncured matrix composite compound for 6 min on a 10-speed gear by a vibrating mixer, and the uncured ferromagnetic composite was prepared by defoaming for 1 min.

[0064] 9.09 wt % of platinum-containing curing agent was added to the uncured ferromagnetic composite, and the curing agent was stirred evenly and then cured. The above operations were completed within 30 minutes. The ferromagnetic composite was obtained by curing at 42 °C for 20 h. The magnetic particles in the ferromag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com