Printing and dyeing stirring equipment

A technology of mixing equipment and mixing tank, which is applied in the direction of mixer accessories, mixers with rotating stirring devices, dissolving, etc., can solve the problems of affecting the service life of precision parts of equipment, reducing the utilization efficiency of dyes, and insufficient mixing of dyes, etc., to achieve Effects that improve convenience, avoid cracks or bends, and avoid clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

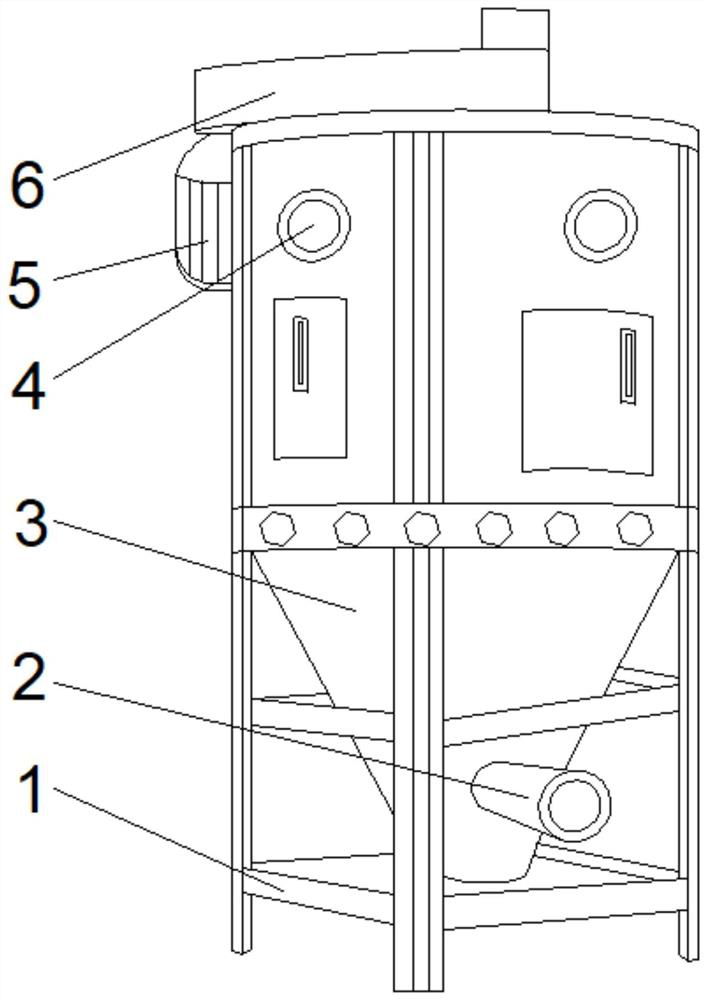

[0033] see Figure 1-2 , the present invention provides a technical solution: a printing and dyeing mixing equipment, including a fixed frame 1, the top of the inner wall on both sides of the fixed frame 1 is fixedly connected with a stirring device 3, and the top of the stirring device 3 is provided with an agitator 6, The top of the left outer wall of the agitator 6 is fixedly connected with a motor 5, the output shaft of the motor 5 is connected with the agitator 6 in rotation, the front and top sides of the agitator 3 are provided with a feed port 4, and the right side of the front bottom of the agitator 3 is connected. There are feed pipes 2.

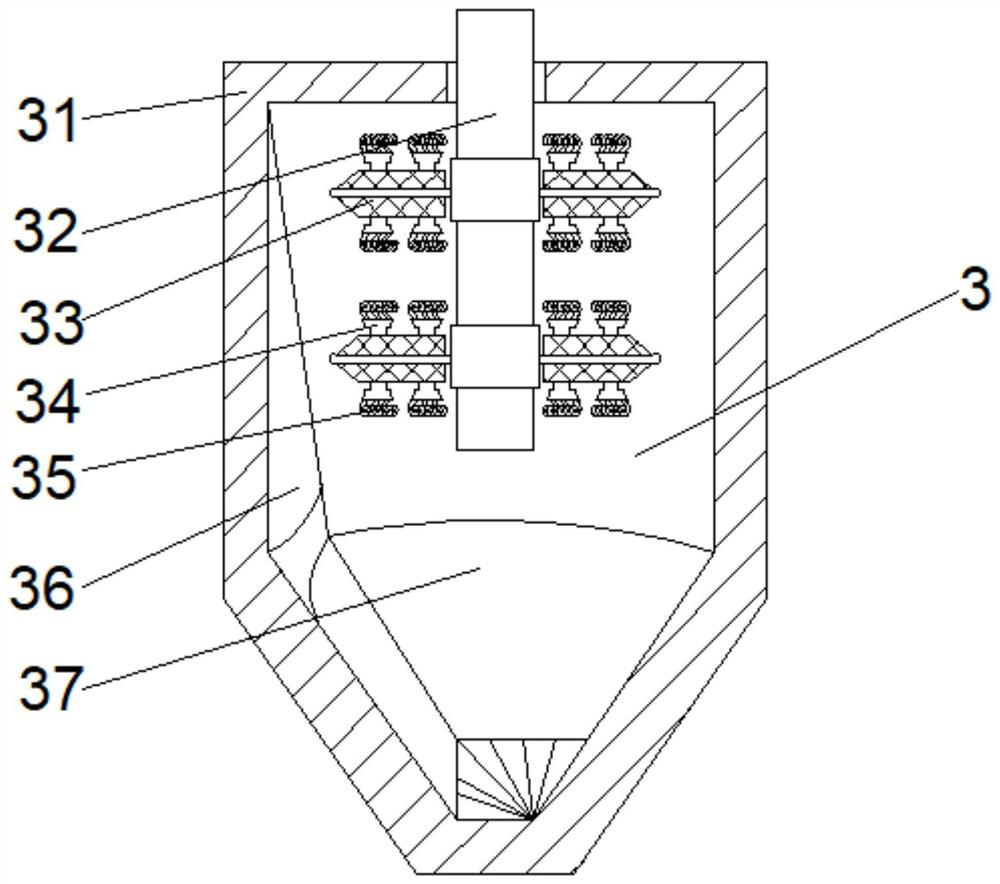

[0034]Wherein, the stirring device 3 includes a stirring tank 31, a stirring shaft 32 is arranged in the middle of the top of the inner chamber of the stirring tank 31, the top of the stirring shaft 32 runs through the stirring tank 31 and extends to the outside of the stirring tank 31, the outer walls of the two sides of the stirr...

Embodiment 2

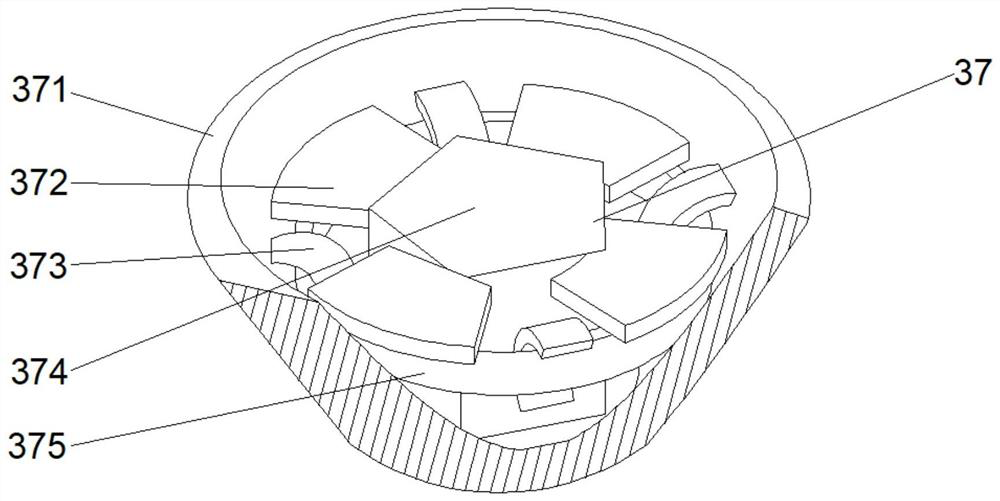

[0037] see Figure 1-4 On the basis of Embodiment 1, the present invention provides a technical solution: the fixing mechanism 37 includes a housing 371, the middle position of the inner cavity bottom of the housing 371 is fixedly connected with an auxiliary mechanism 374, and the top of the outer walls on both sides of the auxiliary mechanism 374 is fixedly connected with The swing plate 372 is provided with an adjustment ring 375 on the top of both sides of the inner wall of the housing 371 .

[0038] Among them, the auxiliary mechanism 374 includes an auxiliary frame d1, the top two sides of the auxiliary frame d1 are fixedly connected with a force-bearing block d7, the bottom of the force-bearing block d7 is provided with an elastic ball d6, and the top sides of the auxiliary frame d1 are located on the sides of the force-bearing block d7. The bottom is fixedly connected with the block d5, the bottom of the block d5 is provided with a rolling ring d3, the left outer wall o...

Embodiment 3

[0041] see Figure 1-6 , on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: the guide mechanism d4 includes a guide frame d41, the top of the guide frame d41 is fixedly connected with a blocking block d44, and the top of the inner cavity of the guide frame d41 is fixedly connected There is an inner connection block d43, the top of the inner cavity of the guide frame d41 is located on both sides of the inner connection block d43 and is fixedly connected with extruding rods d42, and the bottom of the guide frame d41 is fixedly connected with a force plate d45.

[0042] Wherein, the force receiving plate d45 includes a plate body t1, the two sides of the top of the plate body t1 are fixedly connected with telescopic ends t2, and the middle position of the bottom of the plate body t1 is provided with a groove t3.

[0043] When in use, the telescopic end t2 on the plate body t1 can play a fixed role, and it is easy to shrink under pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com