Device for pressing arc-shaped iron plate into conical iron plate through arc-shaped movement

A curved iron plate and curved technology, applied in the field of iron and steel casting, can solve the problems of high labor cost, bacterial infection, affecting product quality, etc., and achieve the effect of high labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

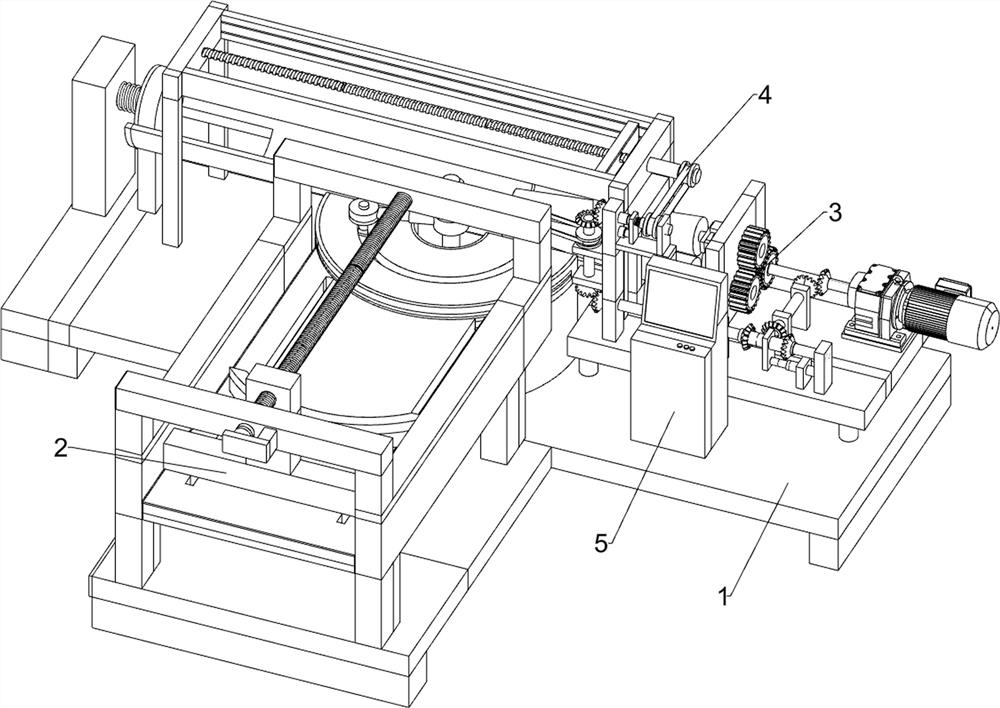

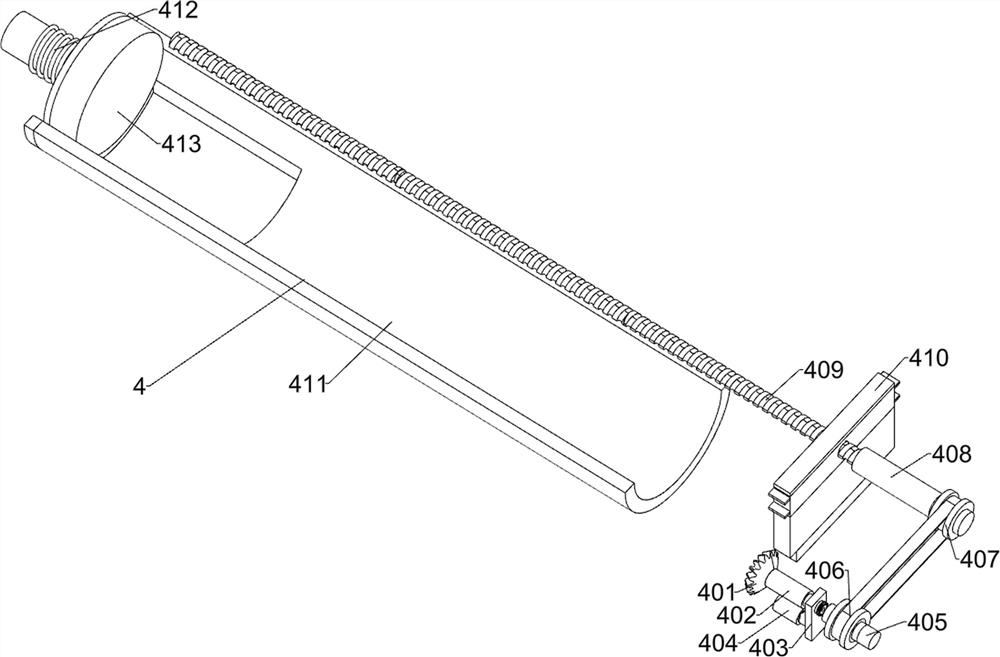

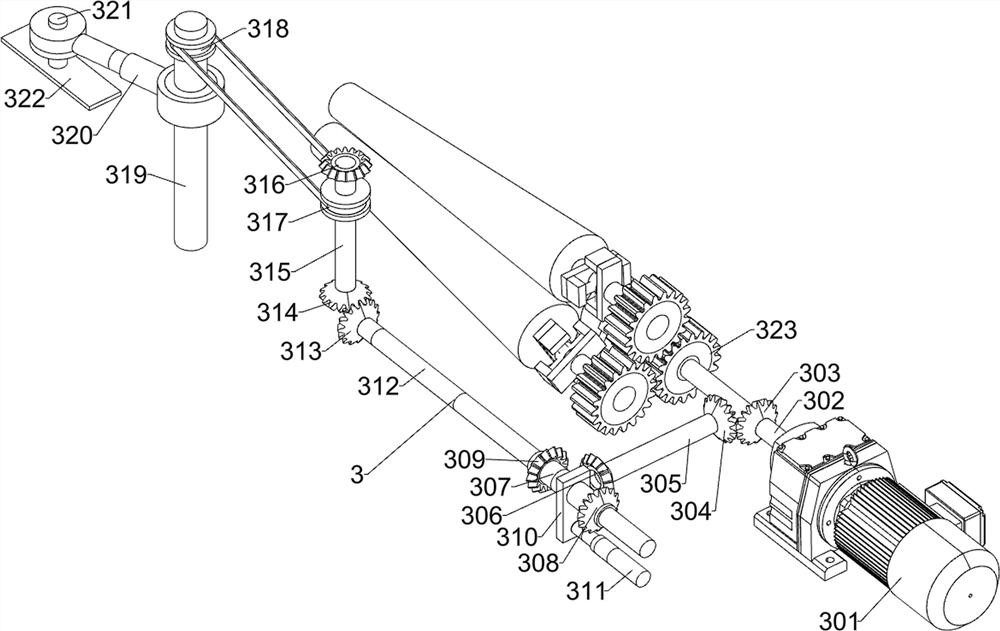

[0029] An arc-shaped iron plate is pressed into a cone-shaped device by arc-shaped movement, such as Figure 1-9 As shown, it includes a bottom plate assembly, a transmission unit, a forming unit, a positive adjustment unit and a control panel; the bottom plate assembly is connected with the transmission unit; the bottom plate assembly is connected with the forming unit; the bottom plate assembly is connected with the positive position adjustment unit; the bottom plate assembly It is connected with the control panel; the transmission unit is connected with the forming unit; the forming unit is connected with the positive adjustment unit.

[0030] Working process: When in use, first press an arc-shaped iron plate into a cone-shaped device through arc-shaped movement and place it at the position to be used, then connect the external power supply and start it through the control panel; firstly, the staff will place the arc-shaped iron plate On the transfer unit fixed on the botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com