Adjustable tool sharpener structure easy to use for machining

A technology for machining and sharpening machines, applied in metal processing equipment, grinding machine parts, manufacturing tools, etc., can solve the problem of dust adsorption on the clothes of the staff, and achieve the effect of reducing the risk factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

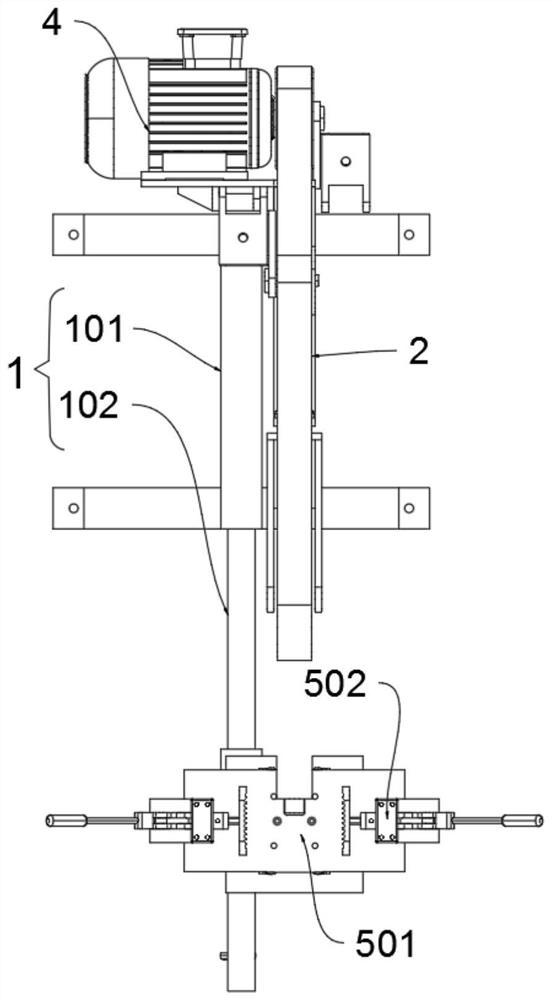

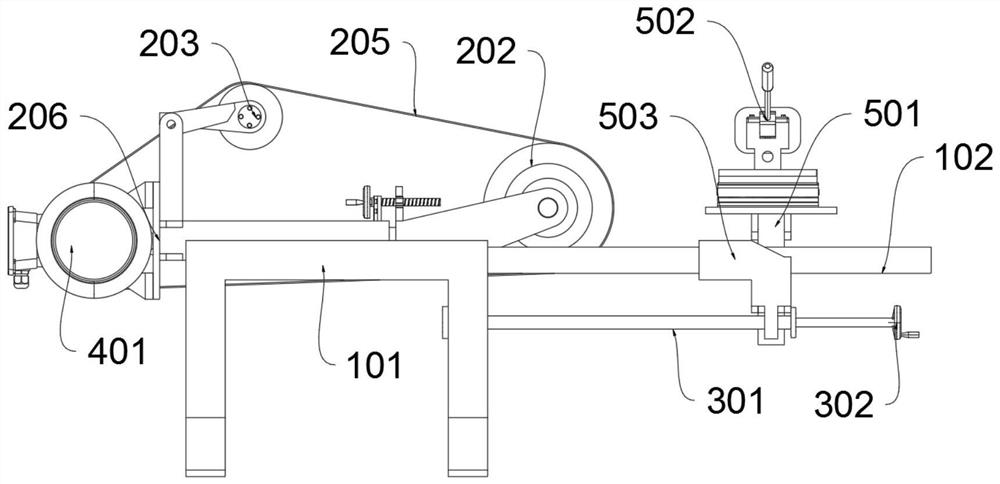

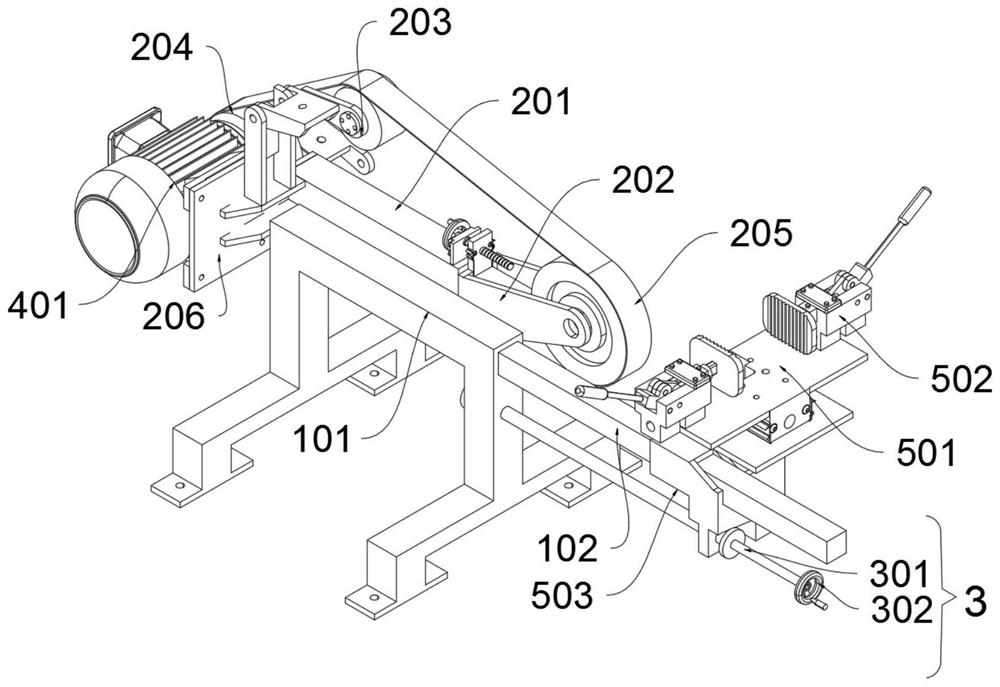

[0029] as attached figure 1 to attach Figure 6 Shown:

[0030] The invention provides an adjustable and easy-to-use knife grinder structure for mechanical processing, including: a support mechanism 1, an adjustment mechanism 3, a power mechanism 4 and a fixing mechanism 5, the position on the right side of the support mechanism 1 and the left side of the grinding mechanism 2 The position is fixed and connected; the adjustment mechanism 3 is rotatably connected to the position below the front end of the support mechanism 1; the power mechanism 4 is fixedly connected to the rear end of the grinding mechanism 2; the fixing mechanism 5 is connected to the front end of the support mechanism 1 through the cooperation of the adjustment mechanism 3; the fixing mechanism 5 includes a fixed plate 501, a clamp 502 and a slider 503. A groove is provided at the middle position of the rear end surface of the fixed plate 501. A clamp 502 is fixedly connected to the left and right ends of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com