Polyethylene foam tape preparing and processing method

A processing method, polyethylene technology, applied in metal processing, etc., can solve problems such as potential safety hazards, staff finger scratches, cutting failures, etc., and achieve the effects of improving safety, avoiding hand scratches, and maintaining a stable position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

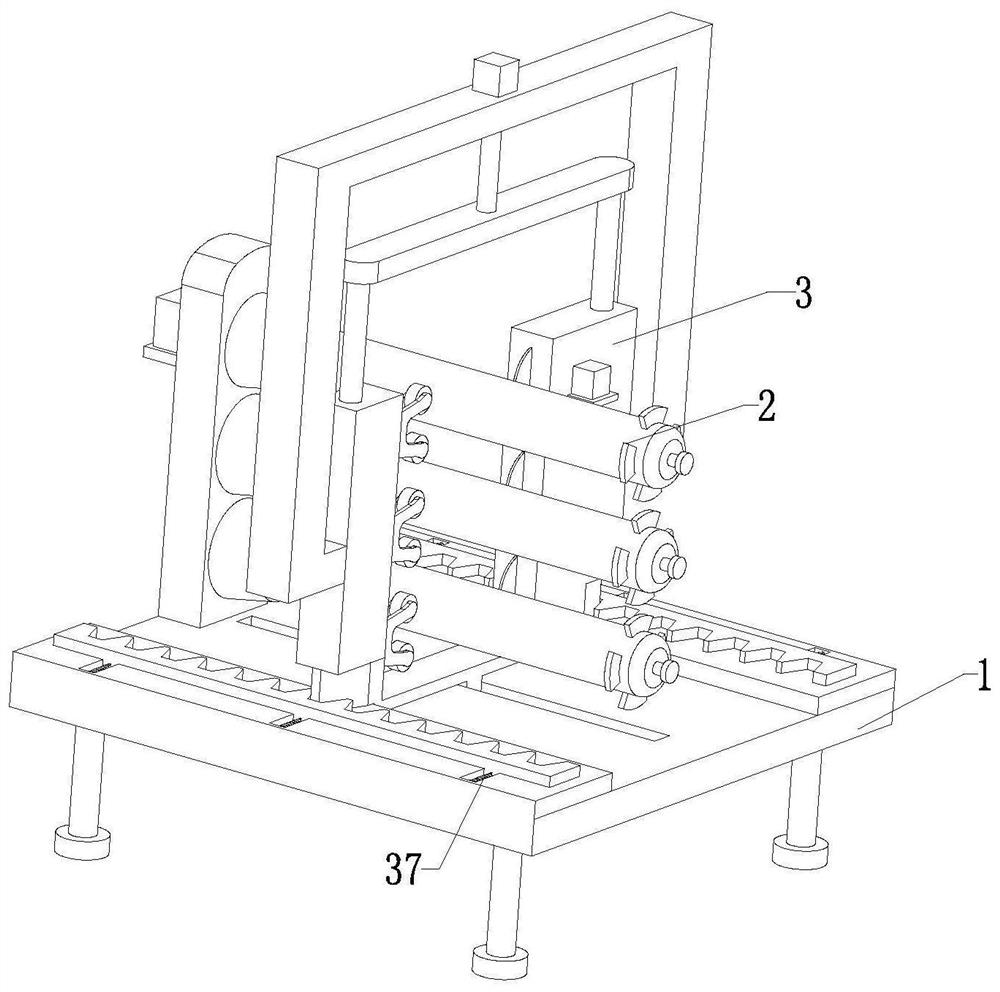

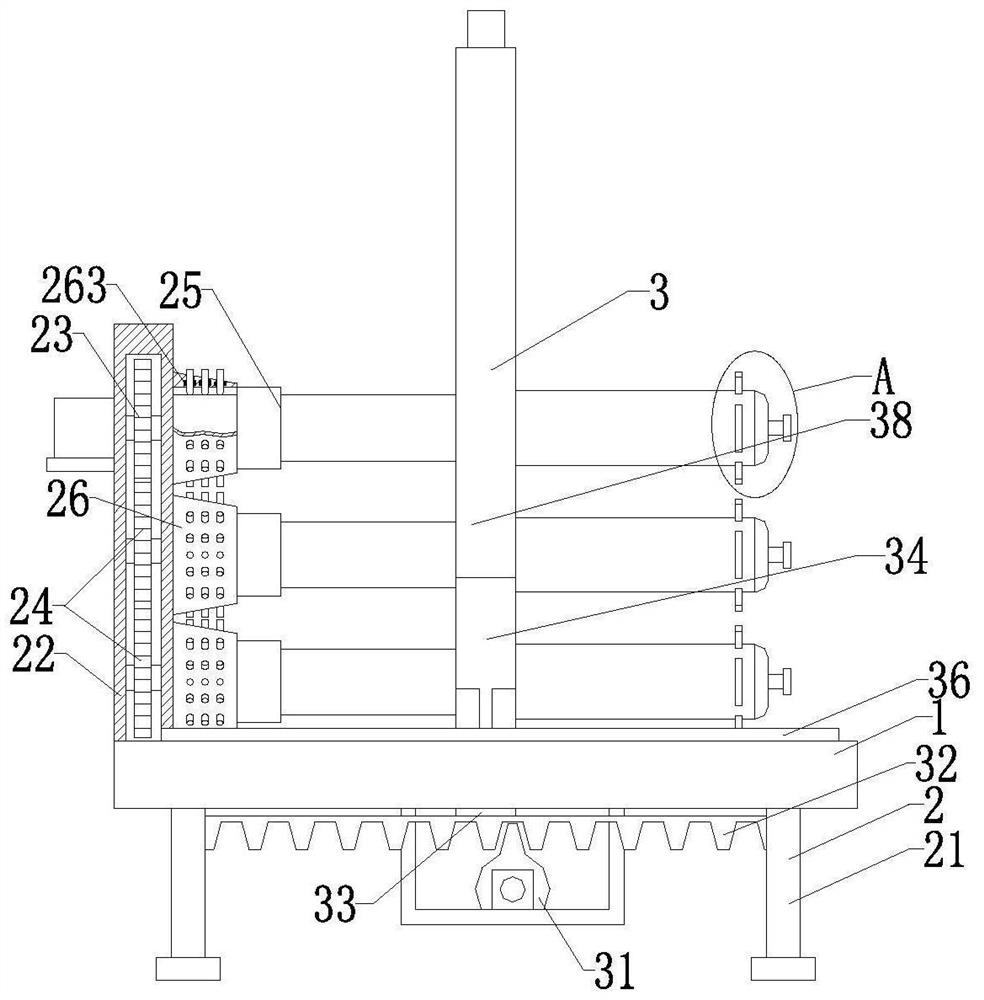

[0033] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

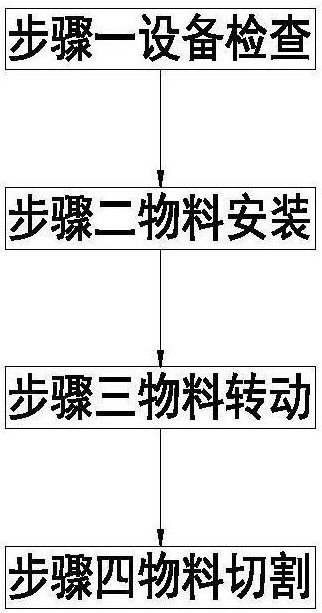

[0034] like Figure 1 to Figure 10 Shown, a kind of polyethylene foam tape preparation and processing method mainly comprises the following steps:

[0035] Step 1: Equipment inspection: before enabling the polyethylene foam tape cutting equipment to cut the polyethylene foam tape, check the operation of the equipment;

[0036] Step 2: Material installation: Manually place the parent roll of polyethylene foam tape that needs to be cut on the charging column 25, and then manually drive the charging column 25 to work to block the outer side of the parent roll of polyethylene foam tape, thereby Complete the material installation work;

[0037] Step 3: Material rotation: After completing the material installation operation in step 2, the No. 1 motor wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com