Method for improving ink precision through two times of printing

An ink and precision technology, applied in the field of improving ink precision by two printings, can solve the problems of ink overflow, existing ink, and low printing precision of ink, and achieve the effect of easy removal and improved precision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

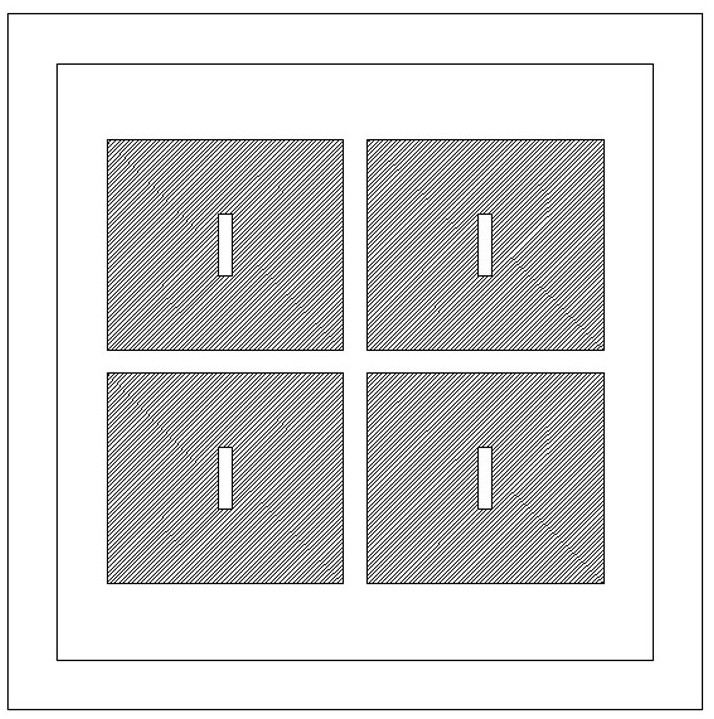

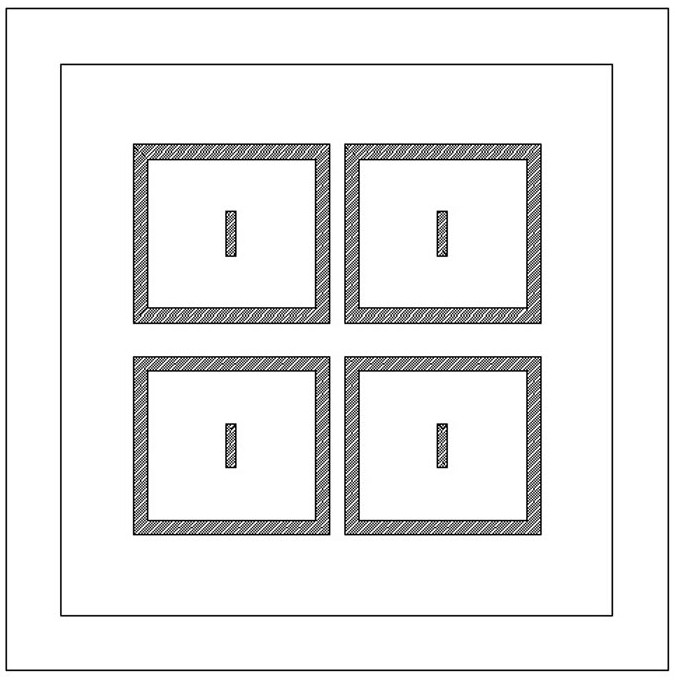

Image

Examples

Embodiment 1

[0034] Embodiment 1: two printings improve the method for printing ink precision, and this method comprises the following steps successively:

[0035] Step 1: According to the ink printing area and non-ink printing area of the printed circuit board, respectively make ink printing screen and dam glue printing screen;

[0036] Step 2: Use dam glue and dam glue printing screen to print the product for the first time, so that the non-ink printing area is covered with dam glue;

[0037] Step 3: Use ink and ink printing screen to print the product for the second time, so that the ink printing area is covered with ink;

[0038] Step 4: Use pre-baking to preliminarily shape the ink;

[0039] Step 5: Remove the dam glue;

[0040] Step 6: Baking again to fully cure the ink.

Embodiment 2

[0041] Embodiment 2: two printings improve the method for printing ink precision, and this method comprises the following steps successively:

[0042] Step 1: According to the ink printing area and non-ink printing area of the printed circuit board, respectively make ink printing screen and dam glue printing screen;

[0043] Step 2: Use dam glue and dam glue printing screen to print the product for the first time, so that the non-ink printing area is covered with dam glue;

[0044] Step 3: Use ink and ink printing screen to print the product for the second time, so that the ink printing area is covered with ink;

[0045] Step 4: Bake the ink to make the ink completely solidified;

[0046] Step 5: Remove the Dam Glue.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com