Fixed-width press hammer head replacement tool and method

A fixed-width press and replacement method technology, which is applied to rolling mill control devices, manufacturing tools, transportation and packaging, etc., can solve problems such as long maintenance time, blocked development, and occupancy of cranes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

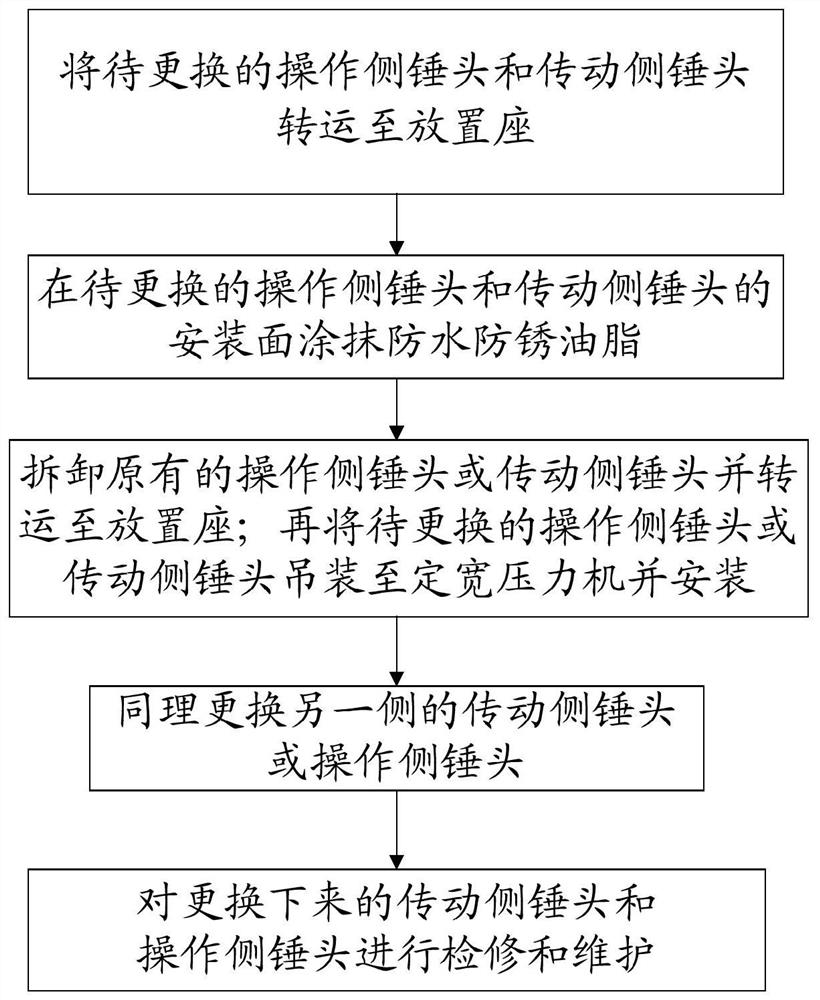

[0030] The core of this specific embodiment is to provide a fixed-width press hammer head replacement tool, which can simplify the hammer head replacement process, improve work efficiency, and solve the current problems in this field.

[0031] Hereinafter, an embodiment will be described with reference to the drawings. In addition, the examples shown below do not limit the content of the invention described in the claims in any way. In addition, all the contents of the configurations shown in the following embodiments are not limited to be essential to the solutions of the invention described in the claims.

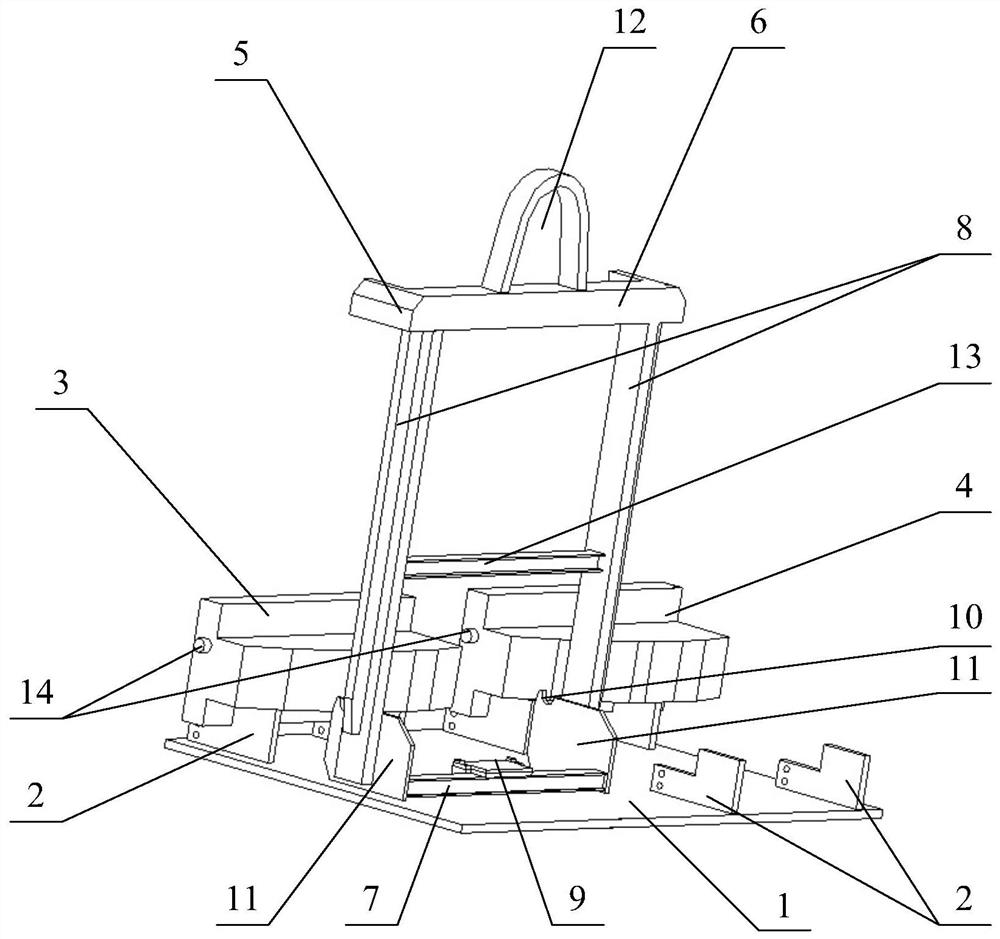

[0032] The fixed-width press hammer head replacement tooling provided in this specific embodiment includes a base plate 1, a placement seat 2 and a spreader 5; wherein, the placement base 2 is three that are arranged on the bottom plate 1, and is used to place the operating side hammer head 3 and The hammer head 4 on the transmission side; the sling 5 is used for hoistin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com