Preparation of high biomass content polyester polyols with hydrogenated itaconic acid

A technology of polyester polyol and polyol, which is applied in the field of preparing high biomass content polyester polyol, can solve the problem that it is difficult to prepare polyester polyol with required chromaticity and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] Preparation method of polyester polyol with high biomass content

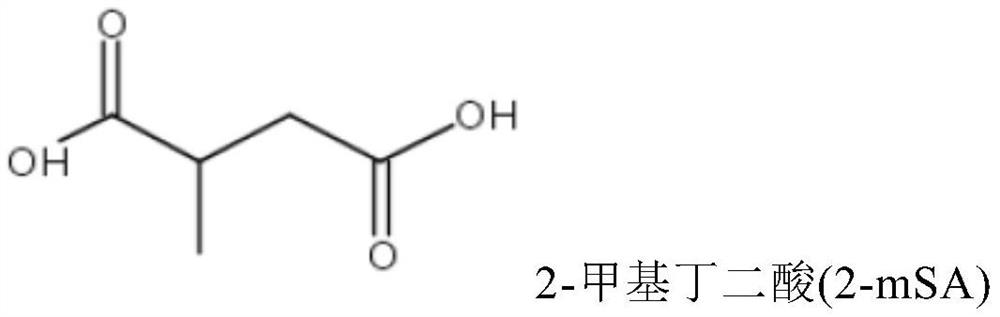

[0033] As mentioned above, the production method of the polyester polyol of the present invention includes reacting 2-methylsuccinic acid with dibasic alcohol and dibasic acid further added as the case may be.

[0034] In a specific example of the present invention, the method for preparing the polyester polyol of high biomass content comprises the following steps at least:

[0035] (1) Add alkyl polyol, alkyl polyacid and antioxidant system to the reactor;

[0036] (2) Carry out the reaction at a temperature not higher than 160°C in a stable gas environment and then increase the reaction temperature to 180-230°C to continue the reaction;

[0037] (3) When the acid value is lower than the first target value, apply a vacuum condition to the reactor and make the reaction continue;

[0038] (4) the reaction is completed when the acid value is lower than the second target value;

[0039] Wherein the alkyl p...

example 1

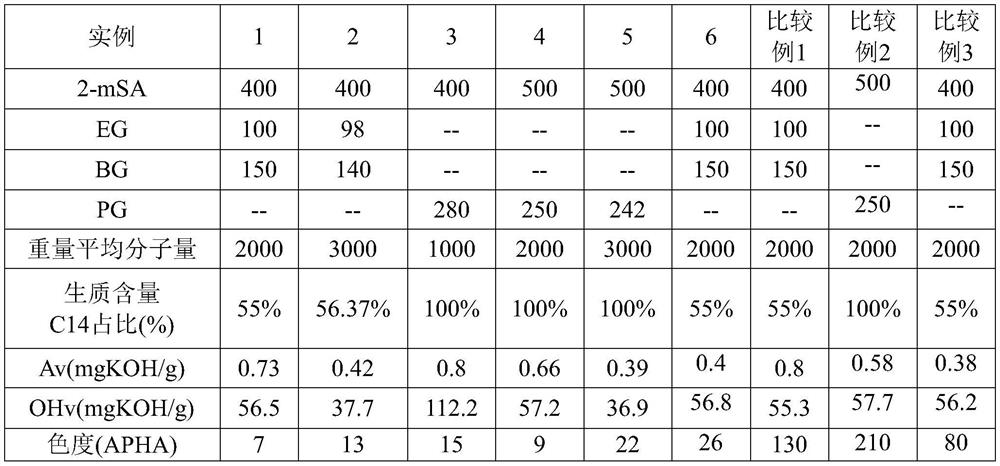

[0054] 2-methylsuccinic acid (2-mSA): 400g, ethylene glycol (EG): 100g, butanediol (BG): 150g, antioxidant 168: 0.06g, antioxidant 5057: 0.02g, T- 9 Catalyst: 0.08g, add to the reaction vessel, heat to 140°C with nitrogen gas and stir for 1 hour, then heat to 180-230°C to react, when the acid value is lower than 20mg KOH / g, vacuumize to gradually increase the vacuum degree to -720torr And maintain the temperature for 7 hours, the acid value is lower than 1 to stop the reaction.

example 2

[0056] Add 2-methylsuccinic acid: 400g, ethylene glycol: 98g, butanediol: 140g, antioxidant 168: 0.06g, antioxidant 5057: 0.02g, T-9 catalyst: 0.08g, into the reaction vessel, Heat to 140°C with nitrogen gas and stir for 1 hour, then heat to 180-230°C to react, when the acid value is lower than 20mg KOH / g, vacuumize to gradually increase the vacuum degree to -720torr and maintain the temperature for 7 hours, the acid value is lower than 1 stop responding

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com