Concrete screen frame device for dam slope protection

A slope protection and concrete technology, which is applied in water supply installations, coastline protection, waterway systems, etc., can solve problems such as easy water seepage, excessive water accumulation in concrete frames, and influence on concrete pouring, and achieve the effect of improving the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

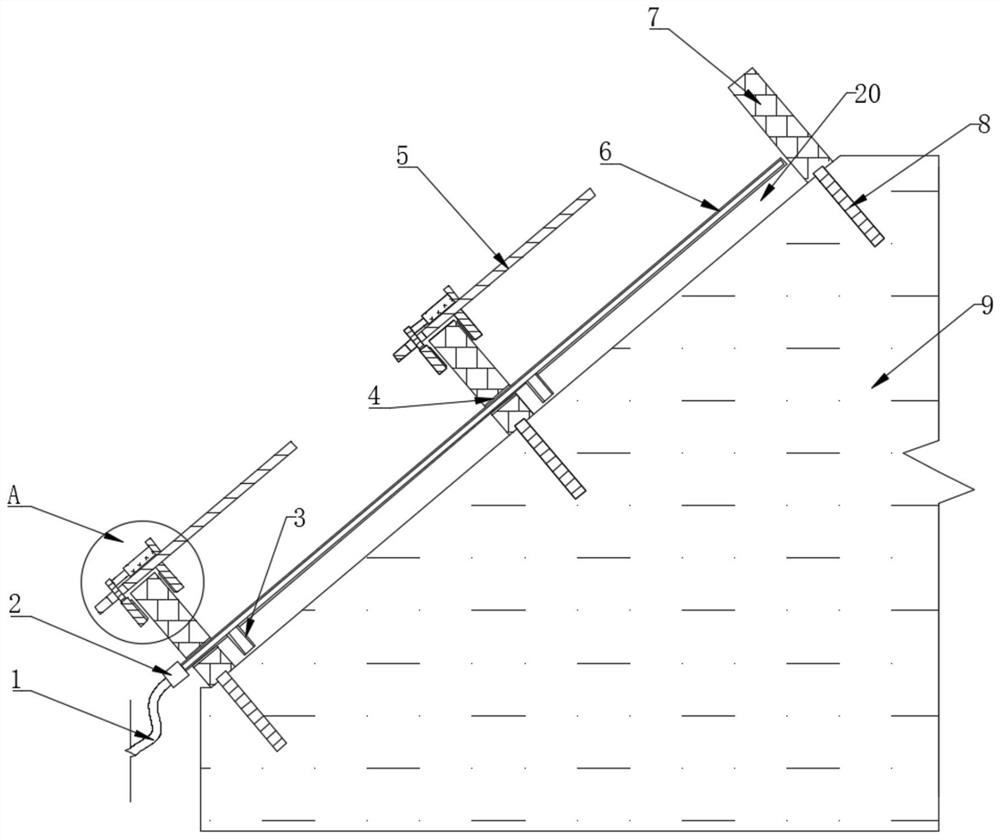

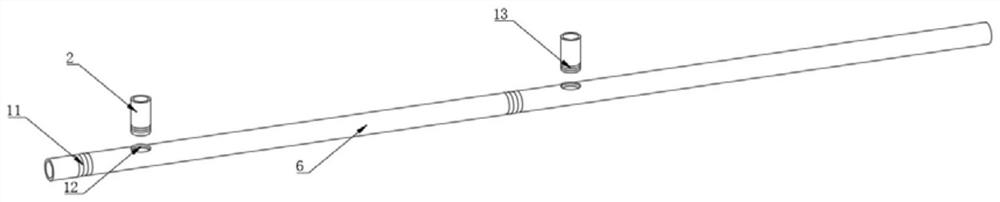

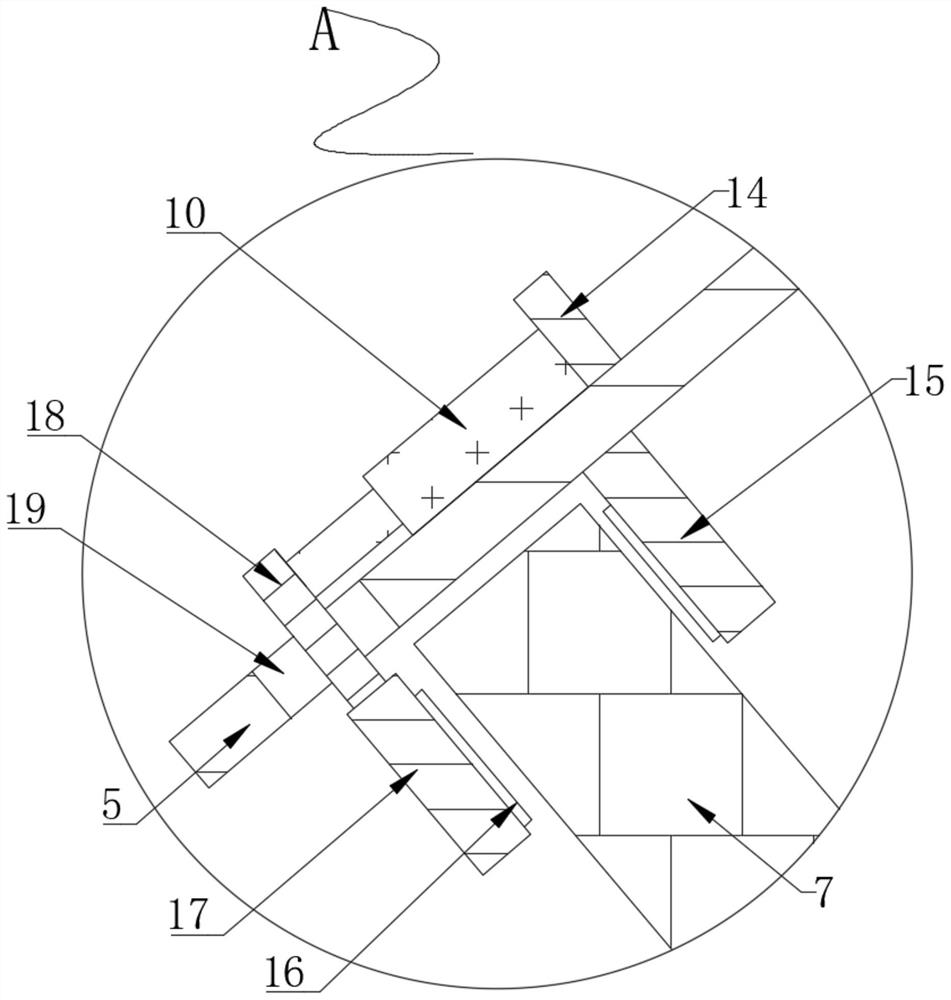

[0021] see Figure 1~3 , in an embodiment of the present invention, a concrete sash device for dam slope protection includes a dam body 9, a plurality of concrete sash 7 are arranged on the top of the dam body 9, and anchor rods are connected to the top of the concrete sash 7 8. Concrete pouring grooves 20 are arranged between two concrete sash grids 7, and drain pipes 6 are connected to one side of several concrete sash grids 7, and threaded holes 4 are provided on one side of the concrete sash grids 7, and drain pipes 6 One end is connected with a water pipe joint 2, and one end of the water pipe joint 2 is provided with a connecting hose 1, and the outer side of the drain pipe 6 is connected with several water pumping pipes 3, and the outer side of the drain pipe 6 is provided with several first fixing threads 11, and the drain pipe 6 A plurality of threaded holes 12 are provided on the outside of the water pipe joint 2, and a second fixing thread 13 is provided on the outs...

Embodiment 2

[0029] refer to figure 1 and 3 , a concrete sash device for dam slope protection. Compared with Embodiment 1, this embodiment also includes anti-slip rubber gaskets 16 on the sides where the compression plate 17 and the support plate 15 are close to each other.

[0030] Working principle: By setting the non-slip rubber gasket 16 on one side of the pressing plate 17 and the supporting plate 15, the two pressing plates 17 can be more firmly opposed to the two sides of the concrete sash 7, so as to be more stable The anti-spill plate 5 is arranged on the top of the concrete sash 7.

[0031] The standard parts used in the present invention can be purchased from the market, and the special-shaped parts can be customized according to the instructions and the records of the accompanying drawings. The specific connection methods of each part adopt mature bolts, rivets, welding, etc. in the prior art. Conventional means, machinery, parts and equipment all adopt conventional models in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com