Double-wheel driving friction coefficient testing device of road friction coefficient testing vehicle

A friction coefficient, two-wheel drive technology, used in measuring devices, mechanical devices, motor vehicles, etc., can solve problems such as distortion of test data, inability to guarantee the stability of test results, etc., to ensure stability, avoid the risk of vehicle runaway, Reasonable effect of structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below in conjunction with examples and specific implementation methods.

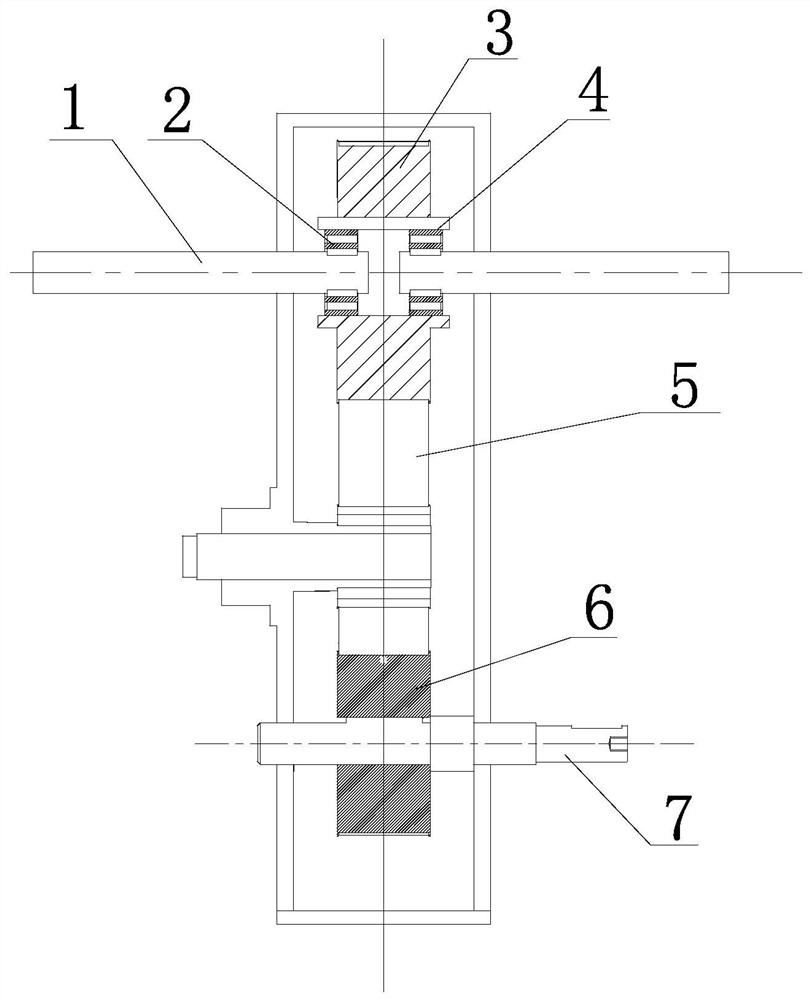

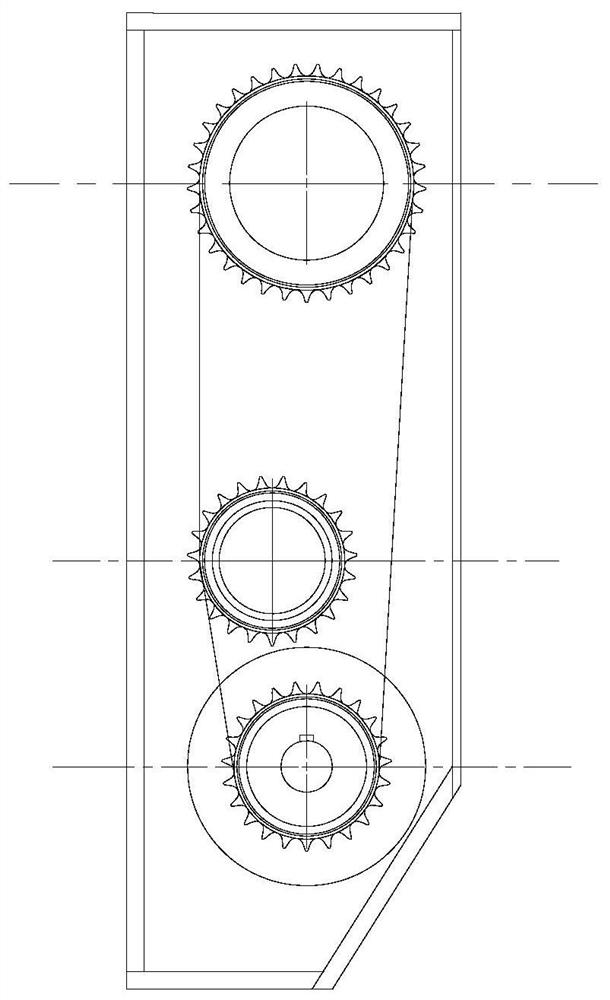

[0013] Such as figure 1 , 2 As shown, a road friction coefficient test vehicle two-wheel drive friction coefficient test device has a structure that the wheels on both sides are respectively connected to the outer end of a transmission shaft 1, and the inner ends of the transmission shaft 1 on both sides are respectively connected to a one-way transmission mechanism 2, Both sides one-way transmission mechanism 2 outsides are connected with the first transmission wheel inner surface 4 of the same first transmission wheel 3, and the first transmission wheel 3 is transmission connected to the transmission chain 5, and the transmission chain 5 is transmission connected to the second transmission wheel 6. The transmission wheel 6 is connected with the test wheel fixed shaft 7, and the test wheel fixed shaft 7 is externally connected with the fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com