Transformer equipment with self-checking function

A technology for transformers and transformer oil, applied in the field of transformers, can solve the problems of transformer structural damage, decreased insulation effect, transformer oil pollution, etc., and achieves the effects of speeding up the flow, reducing the probability of explosion, and improving the cooling work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

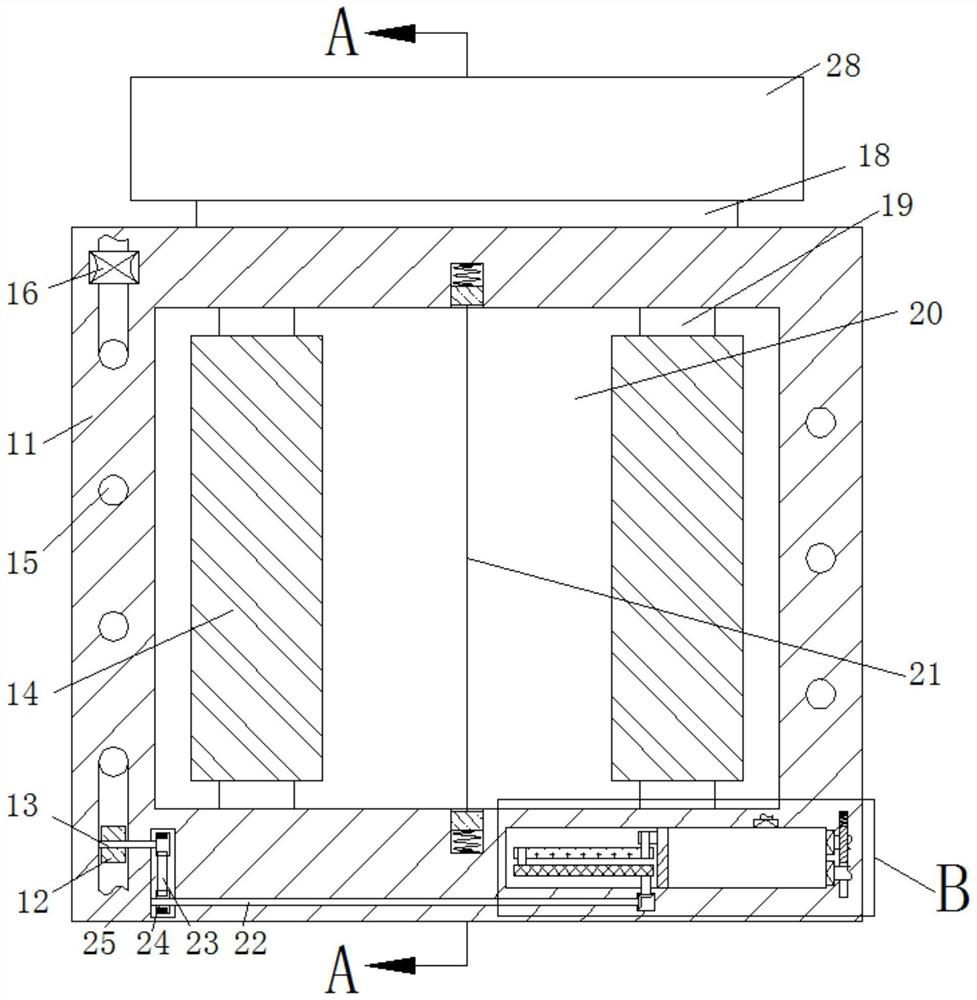

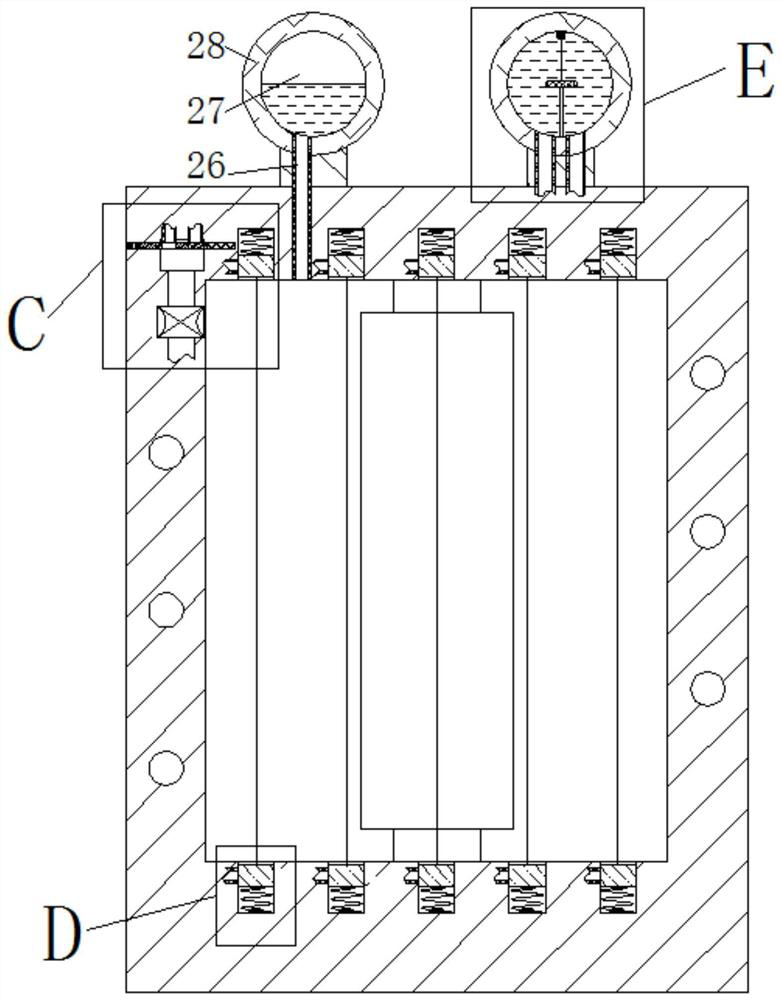

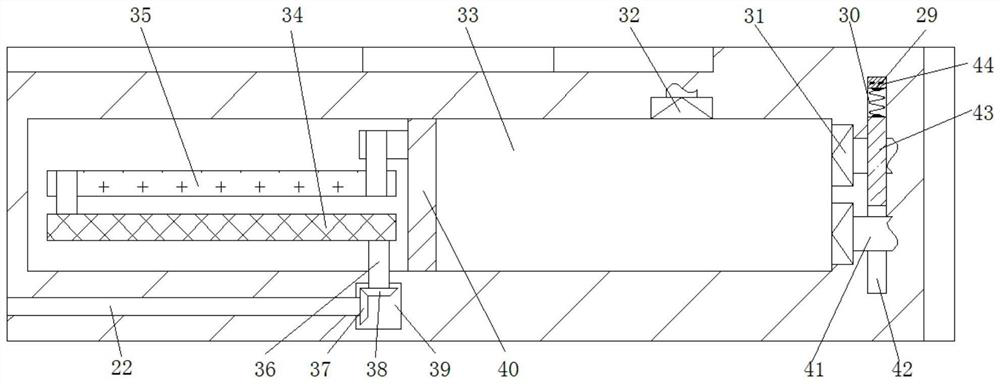

[0019] Combine below Figure 1-6 The present invention is described in detail, wherein, for the convenience of description, the orientations mentioned below are defined as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

[0020]According to the present invention, a transformer device with a self-test function includes a main body 11, a winding cavity 20 is provided in the main body 11, and the winding cavity 20 is filled with transformer oil. The upper and lower sides of the winding cavity 20 A left-right symmetrical winding core 19 is fixed between the walls, and windings 14 are respectively fixed on the outer circular surfaces of the winding core 19 on the left and right sides. The closed block cavity 61, the closed block cavity 61 on the upper and lower sides is respectively provided with a closed block 62 that can slide up and down, and a fuse rope 21 is fixedly connected between the corresponding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com