Welding-free crimping tool for inserting high-speed signal connector into high-density PCB

A PCB board and high-speed signal technology, which is applied in the field of electrical interconnection, can solve the problem of short needle type, save the time of mold installation and disassembly, and achieve the effect of efficient crimping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

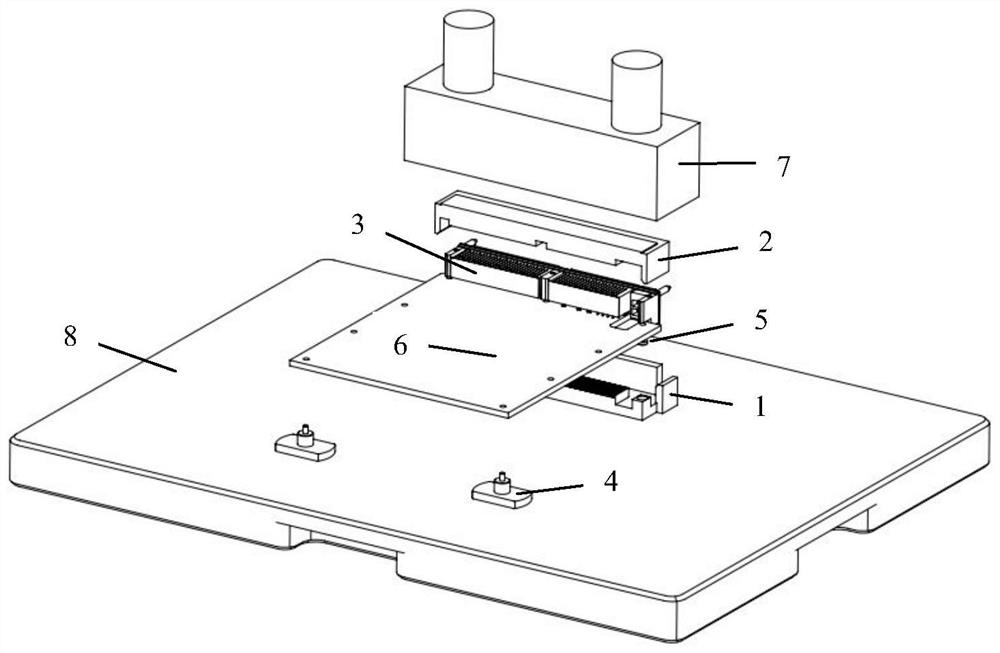

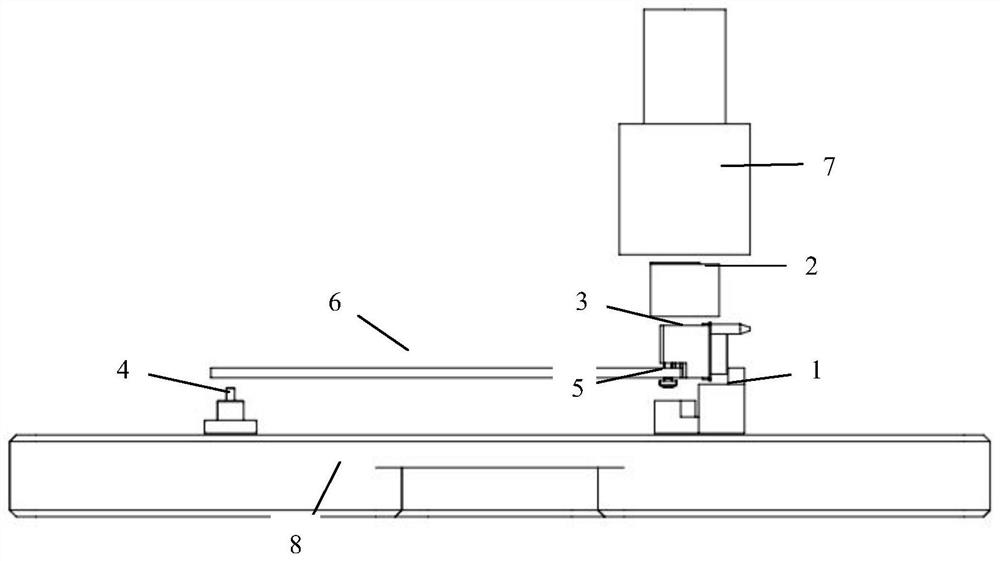

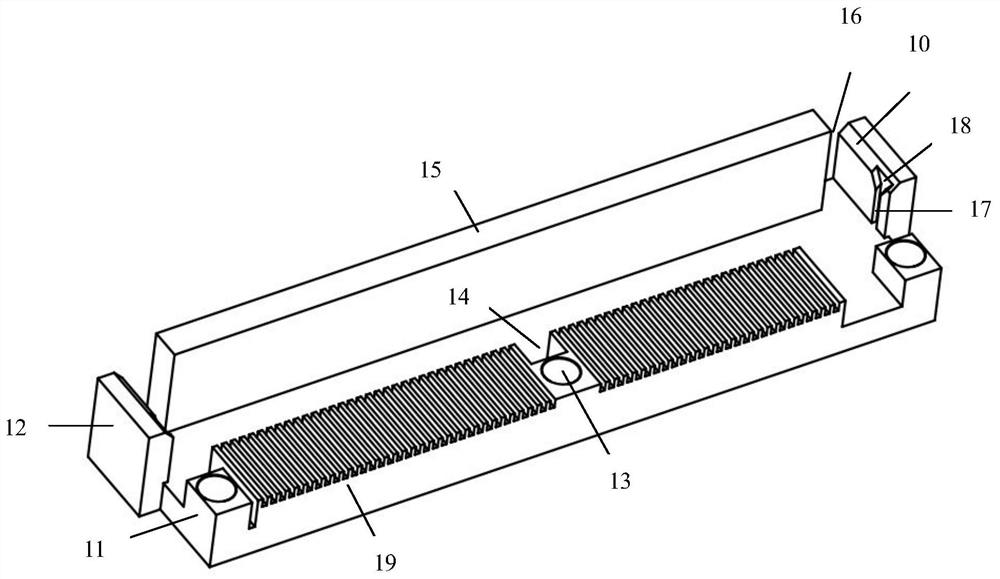

[0023] refer to Figure 1-Figure 6 . In the preferred embodiment described below, a high-density PCB board plug-in high-speed signal connector solderless crimping tooling includes: a base plate 8 placed on the base of the crimping machine, and a press-down tool placed on the base plate 8 Die 1, the upper die 2 on the crimping head 7 of the crimping machine. On both sides of the rectangular body seat of the lower die 1, there are fixedly connected the opposite side limiting plate 12 for symmetrically limiting the connector and the end limiting plate 15 for limiting the freedom of the back end. Between the plate 15 and the opposite side limiting plate 12, there is provided a relief groove 16 to avoid insertion interference with the guide pins 36 on both sides of the plug 3, and corresponding connectors are formed on the inner sides of the two opposite side limiting plates 12 The protruding rail slide bars 32 on both sides of the back plate of the plug 3 are inserted into the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com