A method for preparing a total heat exchange membrane by growing zifs nanoparticles in situ and the prepared membrane

A technology of total heat exchange membrane and nanoparticles, which is applied in the field of preparing total heat exchange membranes and the prepared membranes by growing ZIFs nanoparticles in situ, achieving good moisture permeability and gas barrier performance, easy synthesis method and preparation conditions, and easy solution The effect of reunion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

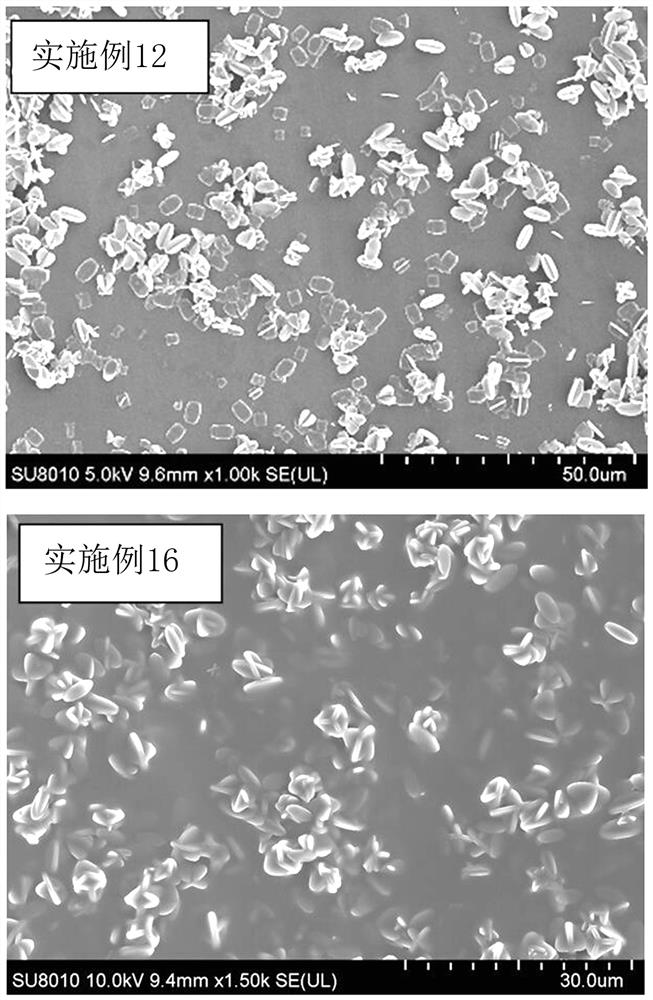

[0029] To prepare a total heat exchange membrane material containing ZIF-8 nanoparticles, the specific steps are as follows:

[0030] Dissolve 6g of polyvinyl alcohol (PVA, type 1799) in 94g of deionized water to prepare a 6wt% PVA aqueous solution, stir and dissolve in a water bath at a constant temperature of 80°C to obtain a basic casting solution;

[0031] Take 1.32g of 2-methylimidazole and dissolve it in a 50g PVA aqueous solution, and name it A solution;

[0032] Take 0.95g of zinc nitrate hexahydrate and dissolve it in another PVA aqueous solution, and name it B solution;

[0033] Add solution B to solution A drop by drop, at 20°C, stir for 5 minutes and react for 5 hours to prepare a casting solution; place the casting solution ultrasonically for defoaming, and use polysulfone ultrafiltration membrane as the bottom in a glass plate frame The film was cast to form a film, the film forming temperature was 30°C, and the film forming time was 24h.

Embodiment 2

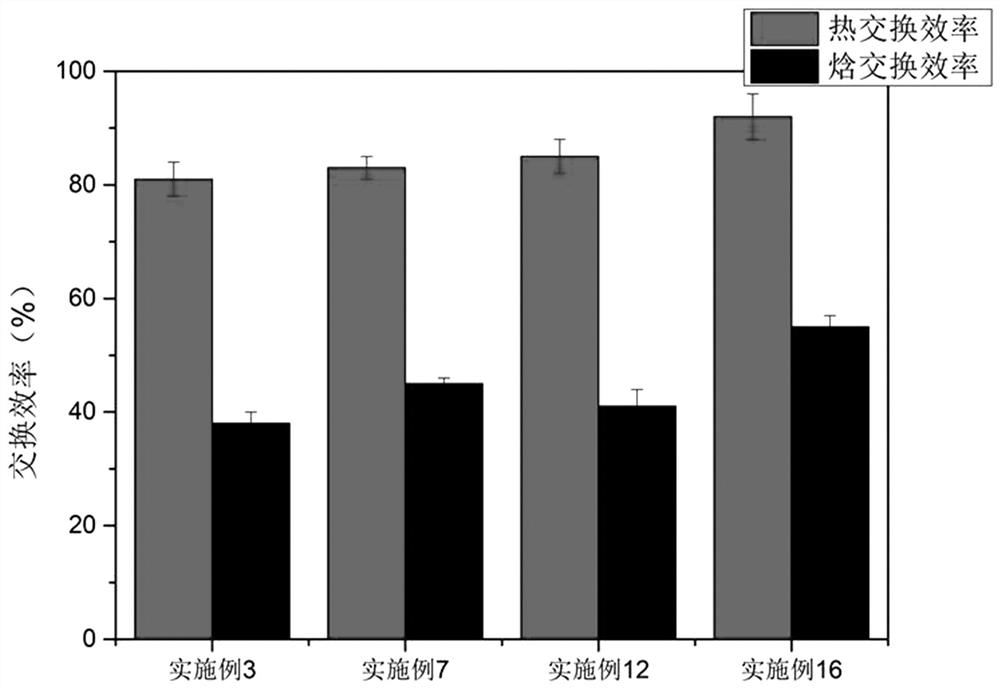

[0035] The method of embodiment 2a-2d is identical with embodiment 1, and difference is that polyvinyl alcohol (PVA, 1799 type) consumption is respectively 4.01g (embodiment 2a), 5.02g (embodiment 2b), 7.00g (embodiment 2b) 2c), 8.01g (embodiment 2d), the concentration of crosslinking agent polyvinyl alcohol is adjusted. It was found that as the concentration of polyvinyl alcohol increased to remain constant, the water vapor transmission rate of the total heat exchange membrane gradually decreased, but the gas barrier property of the membrane gradually increased.

Embodiment 3

[0037] To prepare a total heat exchange membrane material containing ZIF-7 nanoparticles, the specific steps are as follows:

[0038] Dissolve 9g of polyvinyl alcohol (PVA, type 1799) in 141g of deionized water to prepare a 6wt% PVA aqueous solution, stir and dissolve in a water bath at a constant temperature of 80°C to obtain a basic casting solution;

[0039] Take 0.375g of benzimidazole and dissolve it in 75g of PVA aqueous solution, and name it as solution A;

[0040] Zinc nitrate hexahydrate 1.425g was dissolved in another 75g PVA aqueous solution, and named as solution B;

[0041] Add solution B to solution A drop by drop, at 20°C, stir for 5 minutes and react for 5 hours to prepare a casting solution; place the casting solution ultrasonically for defoaming, and use polysulfone ultrafiltration membrane as the bottom in a glass plate frame The film was cast to form a film, the film forming temperature was 30°C, and the film forming time was 24h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com