Whole-process manufacturing method of electric-assisted superplastic forming and aging treatment of aluminum-lithium alloy thin-walled components

An aluminum-lithium alloy and superplastic forming technology, which is applied in the direction of manufacturing tools, forming tools, and metal processing equipment, can solve the problems of slow heating rate of blanks, slow heat transfer rate, surface quality and performance degradation of components, and achieve heating It has the effect of fast cooling speed, shortening the manufacturing cycle and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

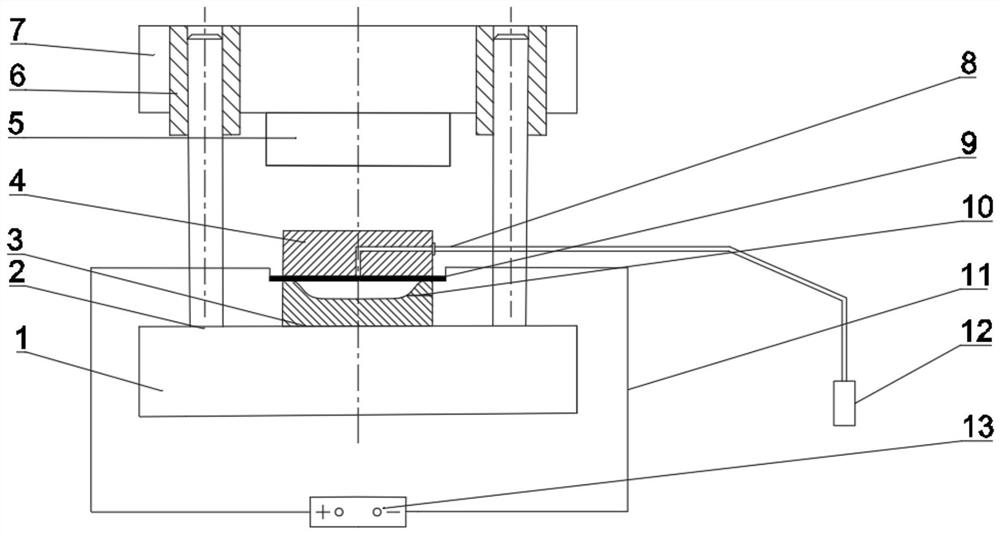

[0026] In this example, the processed mold and the third-generation aluminum-lithium alloy sheet are used as blanks for experiments, such as figure 1 and figure 2 As shown, an electric-assisted superplastic forming device involved in this embodiment includes: an upper die base 7 with a press head 5, a lower die base 1 arranged oppositely, and sequentially arranged on the lower die from bottom to top The die 3 with the vent hole 10 and the punch 4 with the vent pipe 8 on the base 1, wherein: the upper die base 7 and the lower die base 1 are connected through the guide post 2, and the punch 4 is positioned on the die when the die is closed. The aluminum-lithium alloy sheet 9 between the die 3 and the die 3 is formed, the ventilation pipe 8 is fed with inert gas through the inert gas source 12 , and the aluminum-lithium alloy sheet 9 is connected to the low-voltage pulse power supply 13 through the electrode 11 .

[0027] The electric-assisted superplastic forming device is fur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com