Special-shaped plate cutting device and method

A special-shaped plate and cutting technology, used in metal processing and other directions, can solve the problem of inability to quickly adjust the diameter of the cutting arc, and achieve better and diverse cutting effects, a wide range of applications, and fast adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

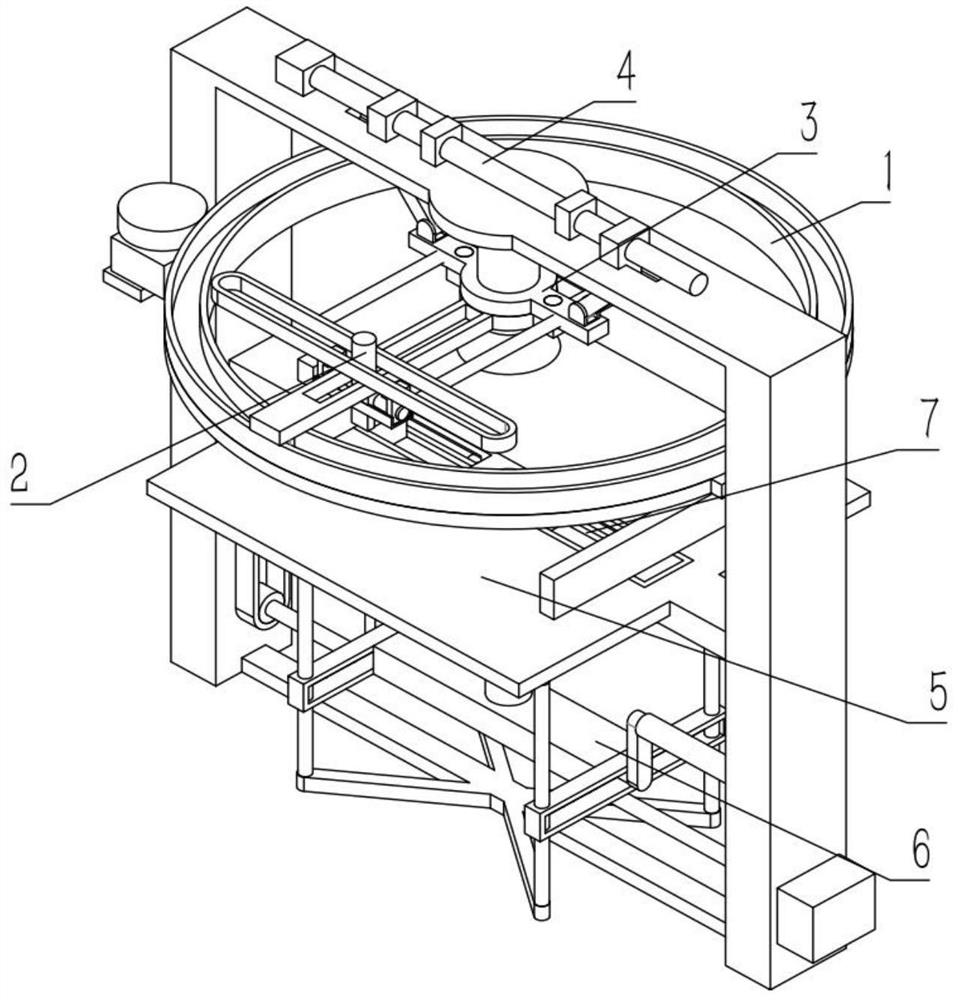

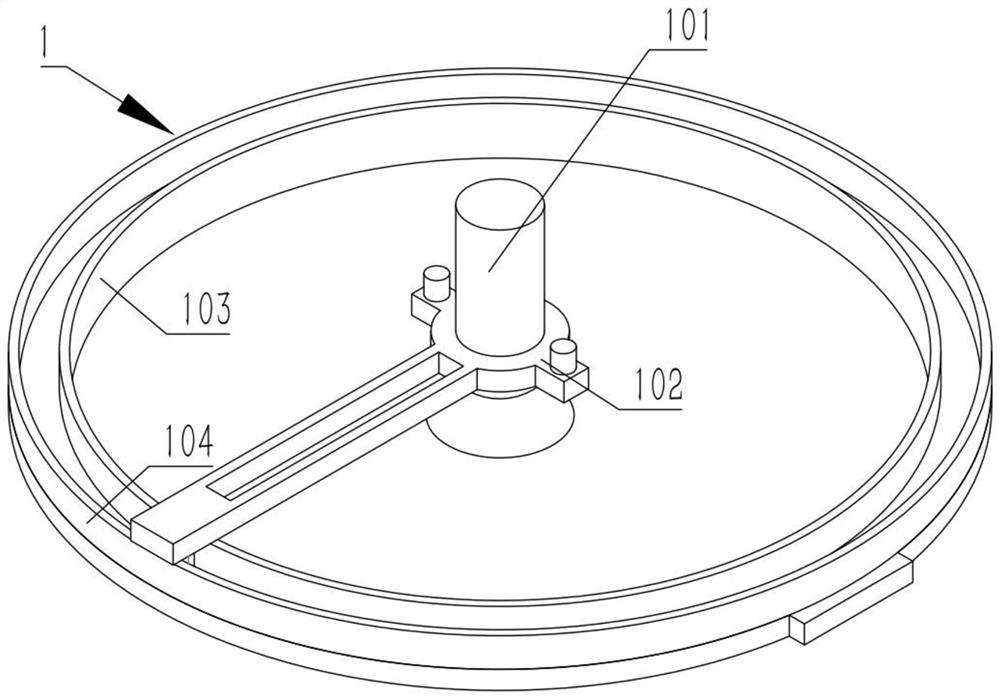

[0034] Combine below Figure 1-8 Describe this embodiment, a special-shaped board cutting device and method, including a rotating mechanism 1 and a cutting mechanism 2, the rotating mechanism 1 includes a fixed rod 101, a rotating frame 102, a rotating track 103 and a rotating gear ring 104, and the rotating frame 102 rotates Connected on the fixed rod 101, the turret 102 is slidably connected on the rotating track 103, the turret 102 is fixedly connected on the rotating gear ring 104, and the rotating gear ring 104 is rotatably connected on the rotating track 103, and the cutting mechanism 2 includes a cutting slide Block 201 and cutting tool 205, and cutting tool 205 is fixedly connected on the cutting slider 201, and cutting slider 201 is slidably connected on the turret 102;

[0035] The device can cut the plate in an arc shape, and can also quickly adjust the required arc radius. The application range is wider, and the adjustment is quick and easy to operate. The cutting ...

specific Embodiment approach 2

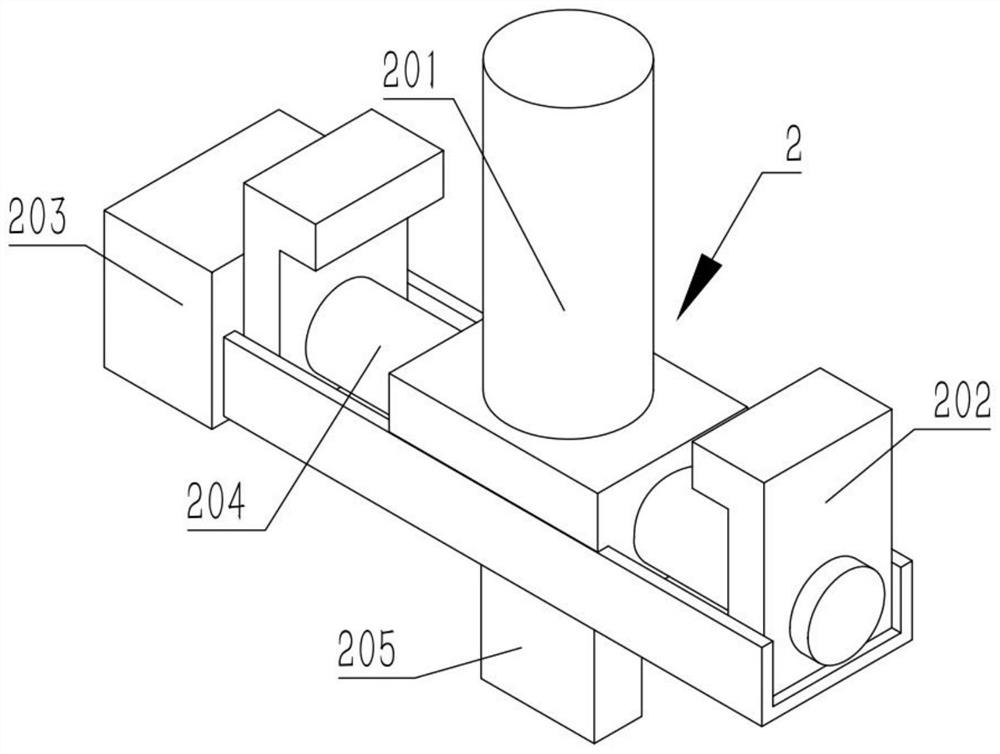

[0037] Combine below Figure 1-8Describe this embodiment, this embodiment will further explain the first embodiment, the cutting mechanism 2 also includes a locking slider 202, a locking motor 203 and a locking screw 204, and the two locking sliders 202 are slidably connected to the cutting slider. On the block 201, the locking motor 203 is fixedly connected on the cutting slider 201, the locking screw mandrel 204 is rotatably connected on the cutting slider 201, the locking screw mandrel 204 and the two locking sliders 202 are threaded, and the locking screw mandrel 204 is fixed Be connected on the output shaft of locking motor 203;

[0038] After adjusting the arc radius that needs to be cut, prevent the cutting slider 201 from moving during the processing, causing the arc radius of the cut to change, wasting materials and causing unnecessary losses, and the cutting slider 201 can be adjusted. Carry out locking, and then the cutting tool 205 is locked, so that the arc effec...

specific Embodiment approach 3

[0040] Combine below Figure 1-8 This embodiment will be described. This embodiment will further explain the second embodiment. The special-shaped plate cutting device also includes an auxiliary mechanism 3. The auxiliary mechanism 3 includes an auxiliary slideway 301, an auxiliary screw rod 302, an auxiliary bracket 303, an auxiliary Motor 304 and auxiliary nut 305, auxiliary slideway 301 are fixedly connected on two auxiliary screw mandrels 302, and two auxiliary screw mandrels 302 are all slidably connected on auxiliary support 303, auxiliary motor 304 is fixedly connected on the auxiliary support 303, auxiliary motor 304 is provided with a gear, and the auxiliary nut 305 on the left end is engaged with the gear on the auxiliary motor 304 for transmission. The two auxiliary nuts 305 are all rotatably connected to the auxiliary bracket 303, and the two auxiliary nuts 305 are threaded with two auxiliary screw rods 302 respectively. transmission, the cutting slider 201 is slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com