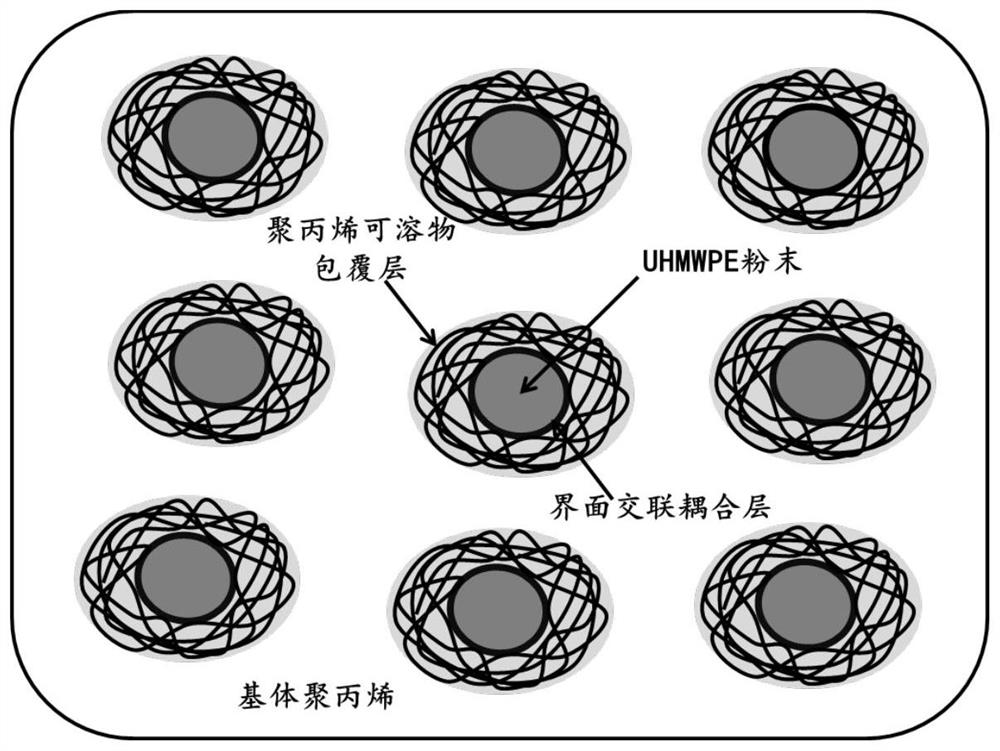

A kind of anti-tiger skin pattern polypropylene composite material for spray-free bottom guard plate and preparation method thereof

A composite material and tiger-skin-resistant technology, which is applied in the field of polypropylene modified materials for spray-free bottom guards and its preparation, can solve the problem of limited compatibility between styrene-butadiene impact-resistant transparent resin and polypropylene, and the reinforcement effect of polypropylene Limited, high extruder process requirements and other problems, to achieve the effect of improving apparent defects, reducing paint spraying process, and good melting state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

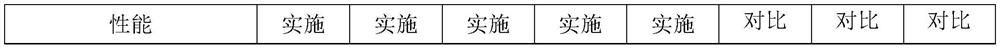

Examples

Embodiment 1

[0067] S1: Place the impact-resistant polypropylene (K7760H) in a xylene solvent and heat it to 140°C and stir to dissolve fully. Wherein the mass of soluble matter is 1kg, after cooling and cooling for 2h, the insoluble matter is filtered with a Buchner funnel to obtain a solution containing 14.4kg of soluble matter;

[0068] S2: Add 20 g of superconducting carbon black, 0.5 g of cross-linking agent DCP and 1 kg of UHMWPE together into a low-temperature grinder and grind them together into powder. Use liquid nitrogen to cool down to minus 100 °C, and rotate at 8000 rpm / min to form superconducting carbon black. and DCP-coated powder UHWMPE10 (particle size less than 10 microns), add 1.0kg UHMWPE10 powder to the S1 solution, stir and mix evenly, then heat and rotate at 80 °C to remove the solvent, and finally obtain 2.0kg of surface soluble matter Coated UHMWPE10 powder;

[0069] S3: Add 20g of calcium carbonate to the above modified powder, stir and mix well to obtain mineral...

Embodiment 2

[0073] S1: Place the impact-resistant polypropylene (SP179P) in a xylene solvent and heat it to 140° C. and stir to fully dissolve. Wherein, the mass of soluble matter is 1.5kg, and after cooling for 2h, the insoluble matter is filtered with a Buchner funnel to obtain 13.1kg of a solution containing soluble matter;

[0074] S2: Add 50 g of superconducting carbon black and 2.4 g of DCP together with 1 kg of UHMWPE into a low-temperature grinder and grind them together into powder. Use liquid nitrogen to cool down to minus 100 °C, and rotate at 8000 rpm / min, and finally form a superconducting carbon black and DCP package. Coated powder UHWMPE5 (particle size is less than 5 microns), add 1.0kg UHMWPE5 powder into the S1 solution, stir and mix evenly, and then remove the solvent by heating and rotary evaporation at 80 °C, and finally obtain 2.5kg of surface soluble matter-coated powder. UHMWPE5 powder;

[0075] S3: Add 50g talc powder to the above modified powder, stir and mix we...

Embodiment 3

[0079] S1: The impact polypropylene (K8303) is placed in a xylene solvent and heated to 140°C and stirred to be fully dissolved, wherein the mass ratio of impact polypropylene and xylene solvent is 1:2, and the mass of impact polypropylene is 9.1kg. Wherein, the mass of soluble matter is 2.0kg, and after cooling for 2h, the insoluble matter is filtered with a Buchner funnel to obtain 20.2kg of a solution containing soluble matter;

[0080] S2: add 90g of zinc oxide and 9g of DCP and 1kg of UHMWPE together into a low-temperature grinder and grind into powder together, use liquid nitrogen to cool down to minus 100 ℃, rotate speed 8000rpm / min, and finally form powder UHWMPE2 ( particle size is less than 2 microns), 1.0kg of UHMWPE2 powder was added to the S1 solution, and then the solvent was removed by heating and rotary evaporation at 80°C, and finally 3.0kg of UHMWPE2 powder coated with surface solubles was obtained;

[0081] S3: Add 90 g of talc powder to the above modified p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap