Underground comprehensive pipe gallery pouring formwork system

A technology of integrated pipe gallery and formwork, applied in formwork/formwork/work frame, connection parts of formwork/formwork/work frame, construction, etc., can solve the problems of low construction efficiency, low efficiency, high labor cost, etc., to achieve Improve construction efficiency, high quality, and improve the effect of lining quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is further described below in conjunction with specific embodiment, and specific embodiment is the further description of the principle of the present invention, does not limit the present invention in any way, and the identical or similar technology of the present invention all does not exceed the scope of protection of the present invention.

[0025] In conjunction with the accompanying drawings.

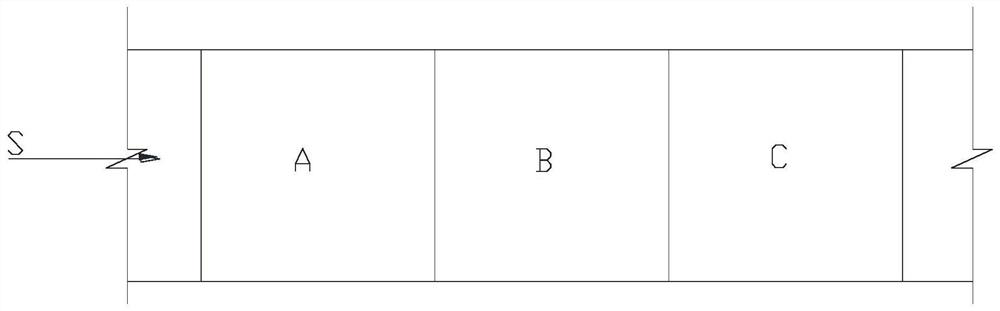

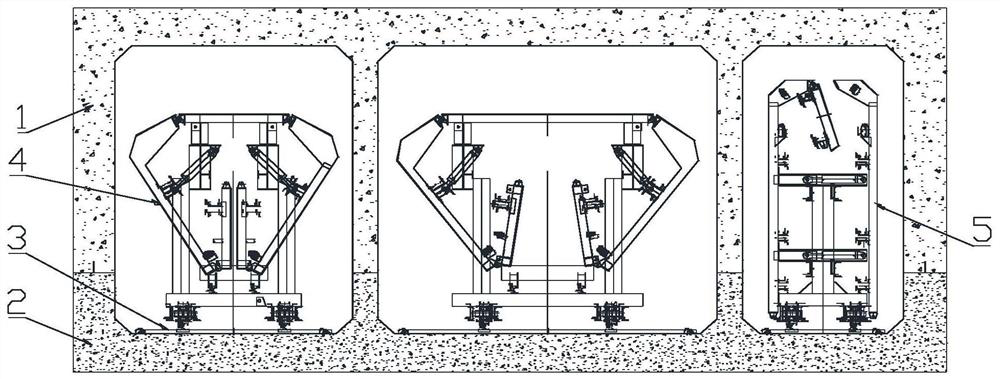

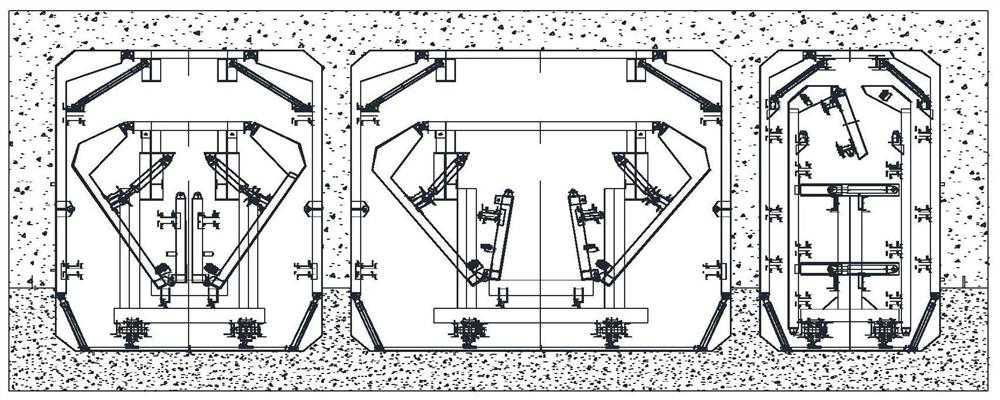

[0026] The pouring formwork system of the underground comprehensive pipe gallery includes the inner formwork and the outer formwork used for the concrete pouring lining of the pipe gallery. Two sets of formwork combinations, both sets of formwork combinations can be moved by trolley 42 to pass through each other to realize alternate and continuous concrete pouring and equal-strength construction.

[0027] The trolley 42 moves along the track 3 laid on the foundation concrete 2 at the bottom of the pipe gallery, and the driving vehicle moves along the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com