A flexible composite lining pipe connection device

A lining pipe, flexible technology, applied in the direction of hose connection devices, pipes/pipe joints/fittings, hoses, etc., can solve the problems of difficult to control the curing time of the adhesive, small application range, uneven thickness, etc., to achieve Significant economic benefits, reasonable and practical structural design, and high-quality lining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

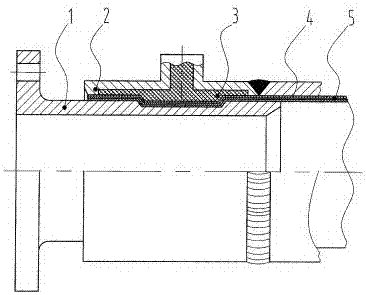

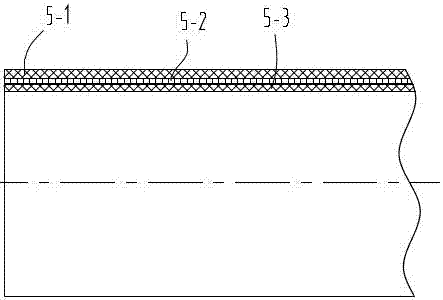

[0008] like figure 1 , figure 2 As shown, a flexible composite lining pipe connecting device is mainly composed of a connecting head 1, an outer sleeve 2, a cured product 3, a pipeline 4, a flexible composite lining pipe 5, a protective layer 5-1, and an aramid fiber reinforced layer 5. -2. The anti-seepage inner film layer is composed of 5-3; the protective layer 5-1, the aramid fiber reinforced layer 5-2, and the anti-seepage inner film layer 5-3 are stacked and solidified into a cylindrical structure. 5-1 is the outer layer, the anti-seepage inner film layer 5-3 is the inner layer, the aramid fiber reinforced fiber layer 5-2 is between the two, the flexible composite lining pipe 5 is lined in the pipe 4, and the aramid fiber reinforced fiber Layer 5-2 is initially a diamond-shaped mesh structure, which makes it easy to change the shape of the cylindrical flexible composite lining pipe, which is convenient for installation operations and does not damage its internal struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com