A Segment Secondary Lining Equipment with Continuous Tension

A secondary lining and segment technology, applied in the shaft lining, tunnel lining, mining equipment, etc., can solve the problems of easily damaged tunnels, weak structural strength, tunnel damage, etc., to avoid damage, strong adaptability, and wide adaptability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

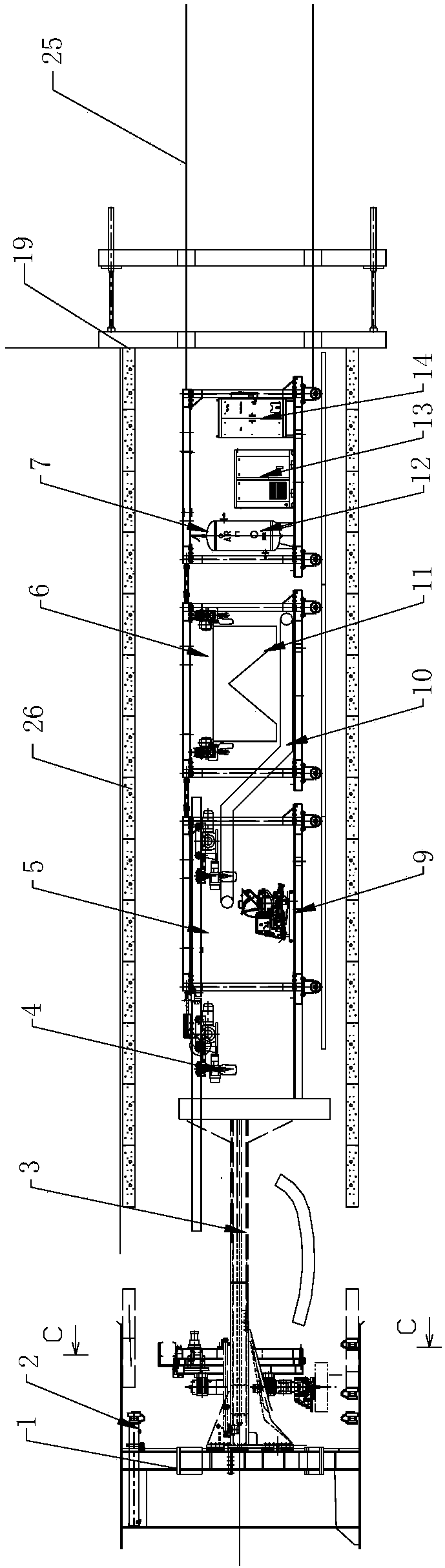

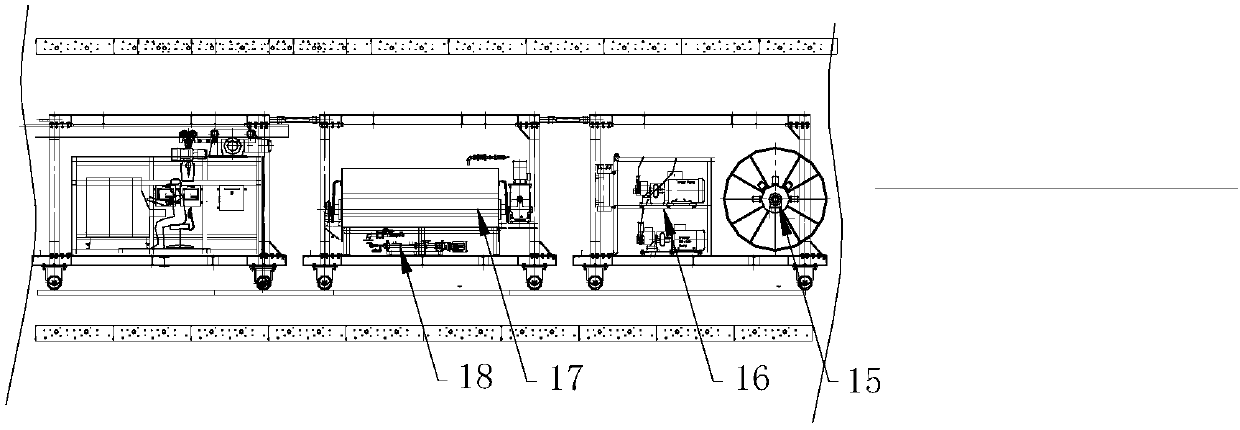

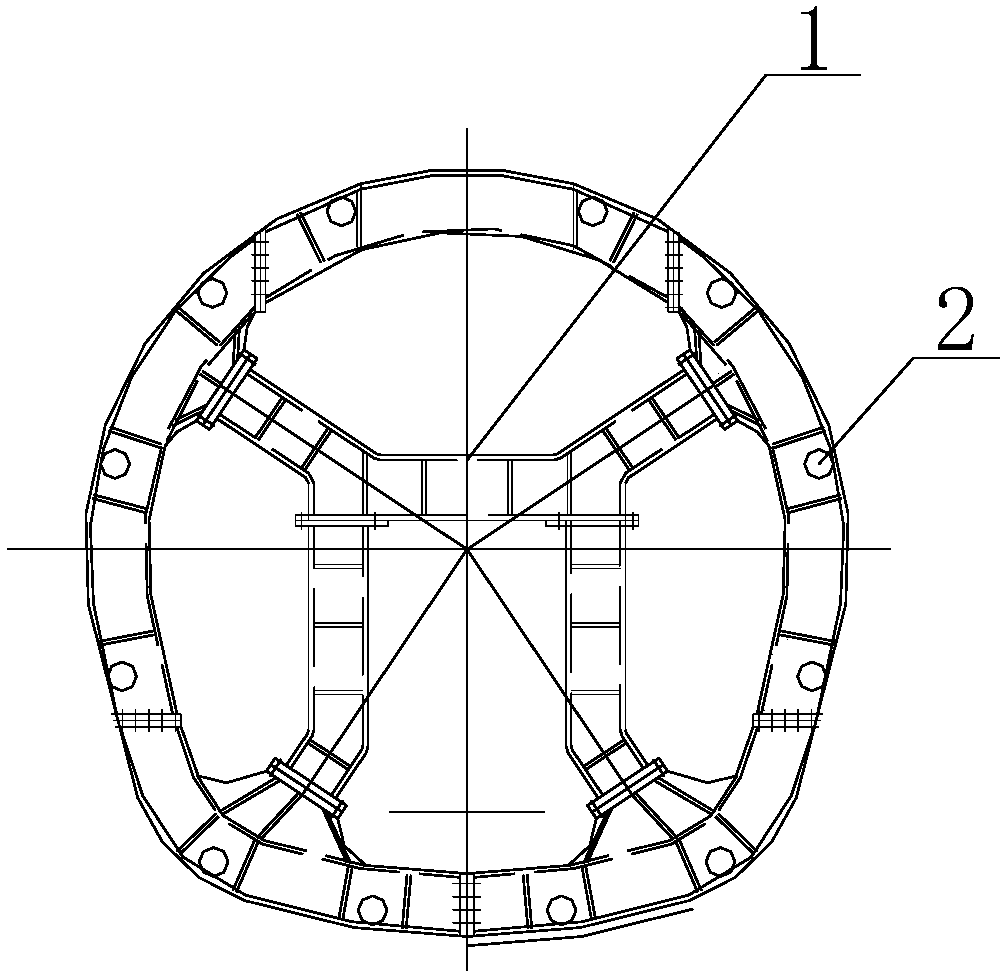

[0022] like Figure 1-5 As shown, this embodiment provides a segmental secondary lining equipment with continuous tension, which includes a car body, and a support shield 1 is arranged at the front end of the car body, and the support shield 1 includes a similar circular support shell , the supporting shell is composed of rice-shaped steel beams, a connecting device is fixedly connected with the car body in the center of the supporting shell, and a plurality of segments for supporting the secondary lining are arranged in the circumferential direction of the supporting shield shell. The propulsion oil cylinder 2 that promotes equipment to advance. The car body is equipped with segment assembly machine 3, segment crane 4, bean gravel injection system, mortar injection system, trolley 5, trolley 6, trolley 7, hydraulic system, compressed air system, electric control syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com