Additional damping type nonlinear gas spring

A technology of additional damping and gas springs, applied in protective buildings/shelters, building components, shockproof, etc., can solve the problems that gas springs do not have additional damping properties, and it is difficult to meet the requirements for the use of tuned mass dampers. Control effect, good social and economic benefits, and the effect of reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

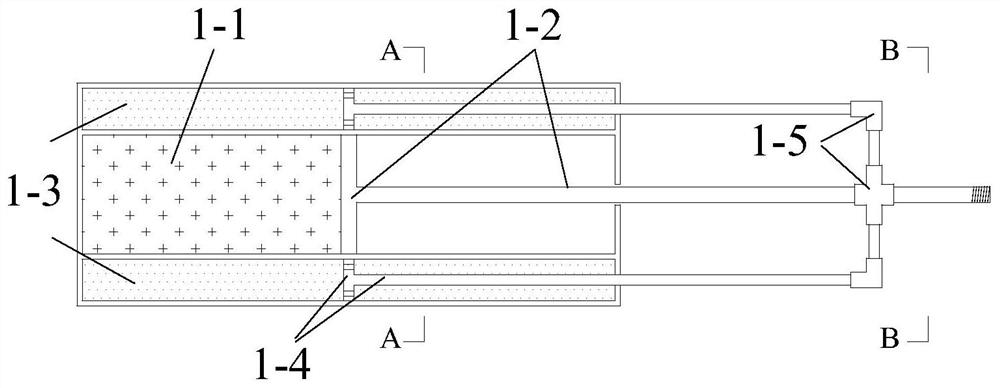

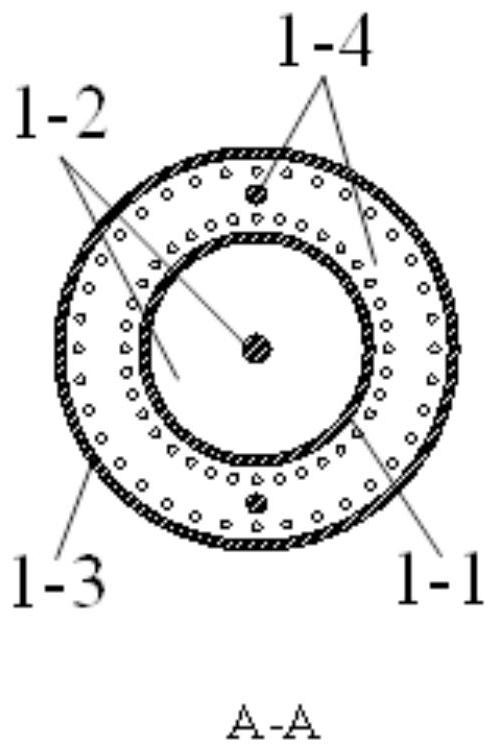

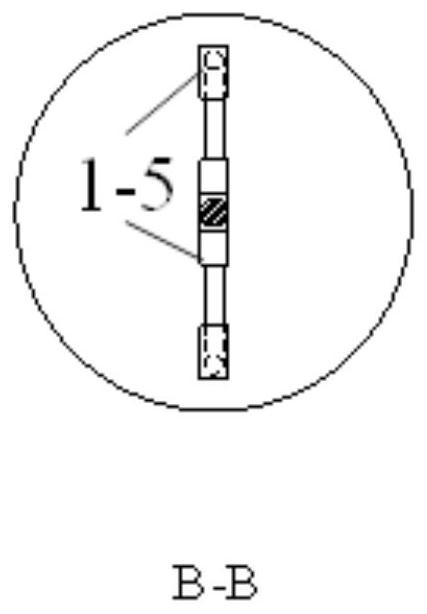

[0028] The additional damping nonlinear gas spring 1 of the present invention has an integrated mechanism of stiffness and damping, and is structured as a concentric cylinder, such as Figure 1-3 , the middle cylinder cavity 1-1 is the gas spring, 1-2 is the piston and piston rod of the gas spring, the ring cavity 1-3 is the damping cavity, 1-4 is the piston and piston rod of the damping cavity, 1-5 at the end of the piston rod is a sleeve connector.

[0029] refer to figure 2 , a nonlinear gas spring tuned mass damper with additional damping nonlinear gas spring, including gas spring 1, mass block 2, slide rail 3, middle support 4 and edge support 5. The mass block 2 is constructed of I-shaped steel, which is milled as a whole. The middle web has holes and is connected to the gas spring 1. The lower flange plate has bolt holes to connect ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com