A composite cross-arm structure

A cross-arm, together technology, applied in the direction of towers, building types, buildings, etc., can solve the problems of composite cross-arm failure, stress concentration, stiffness difference, etc., to achieve the effect of improving bearing capacity, improving bearing capacity, and reducing stiffness changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

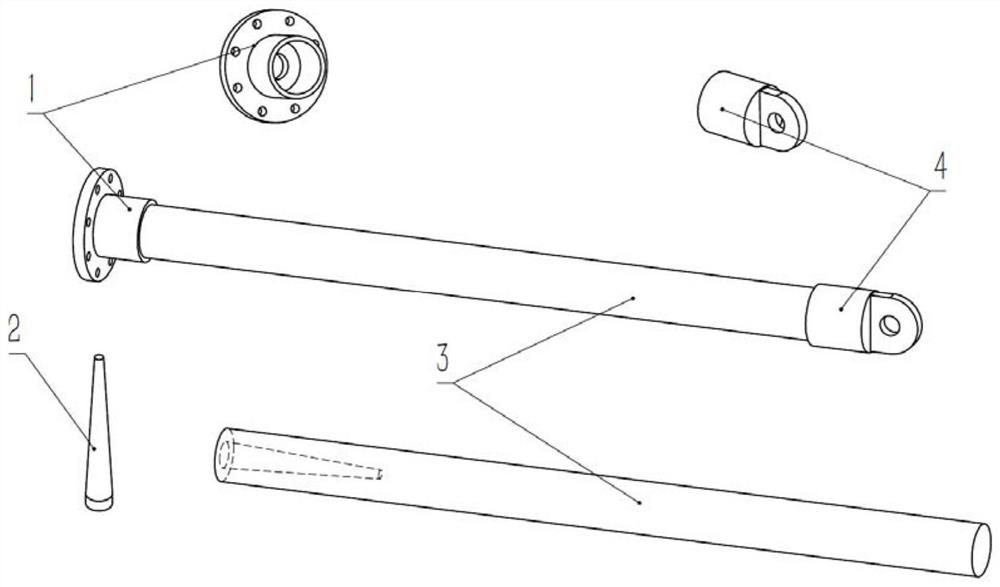

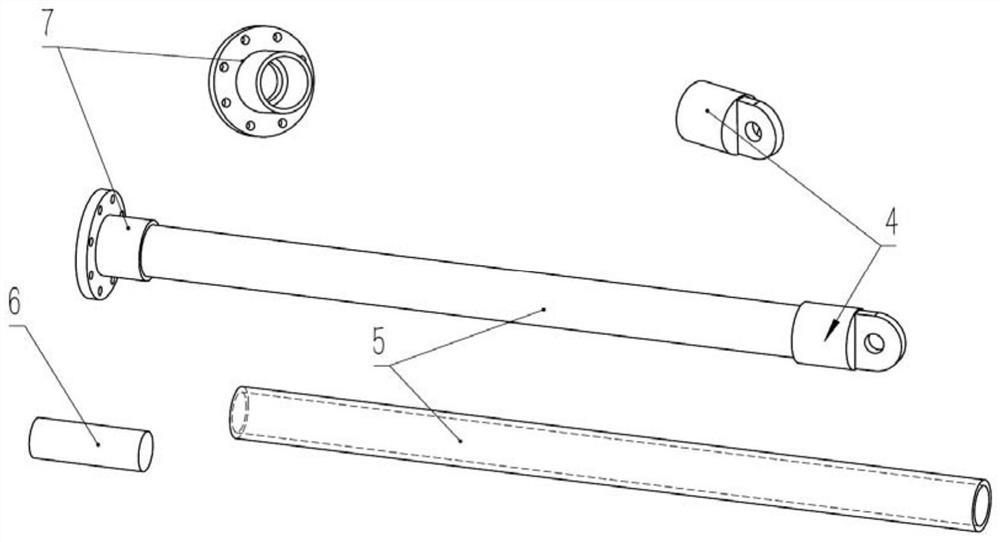

[0026] Such as Figure 1-2 As shown, the present invention provides a technical solution, a composite cross-arm structure, including flanges, inner shafts, mandrels, and end connectors 4. The flanges include A-type flanges 1 and B-type flanges. There are two types of flange 7, the inner shaft has two types of A-type inner shaft 2 and B-type inner shaft 6, and the A-type flange 1 and A-type inner shaft 2 are used for the connection of the extruded mandrel 3, which is convenient for the A-type inner shaft 2 for installation, after the extruded mandrel 3 is extruded, a hole with the same length as the A-type inner shaft 2 and 20mm smaller than the A-type inner shaft 2 is processed at one end, and the B-type flange 7 and B The inner shaft 6 is applied to the connection of the winding mandrel 5, which is convenient for installing the B-type inner shaft 6. When the winding mandrel 5 is wound and formed, the glass fiber is wound on the B-type inner shaft 6 and the mold, so that the B...

Embodiment 2

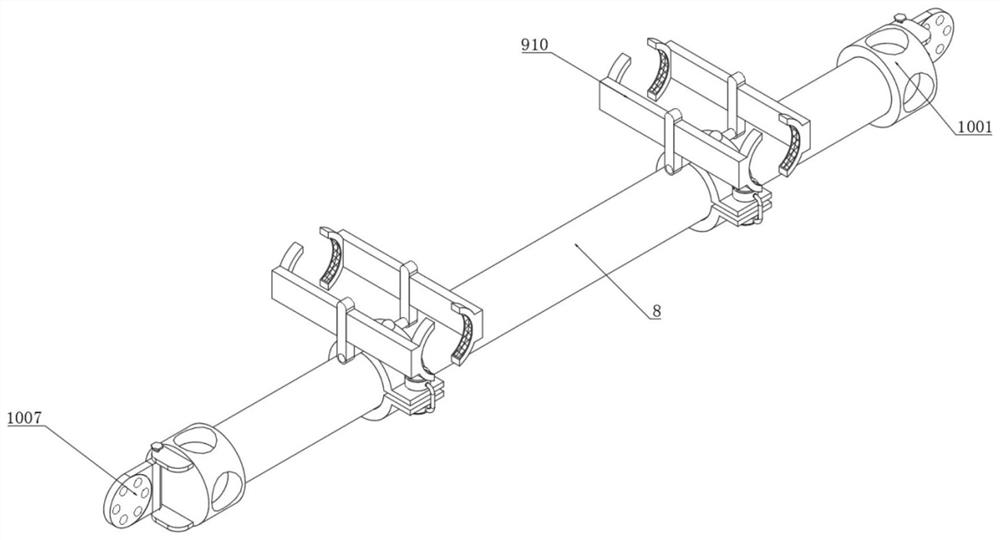

[0036] Such as Figure 3-6 As shown, the present invention provides a technical solution, a composite cross-arm assembly and fixing structure, including a connecting rod 8, and a placing mechanism 9 is symmetrically installed on the outer end of the connecting rod 8, and the placing mechanism 9 includes a clamp 901, a first threaded hole 902 , fastening bolt 903, first bolt seat 904, protective sleeve 905, rubber connecting rod 906, rolling ball 907, fixed rod 908, support plate 909, extension plate 910, limit plate 911, embedded groove 912, rubber pad 913 and Anti-slip mat 914;

[0037]The outer end of the connecting rod 8 is symmetrically slidably sleeved with a clamp 901. A first threaded hole 902 is provided at one side of the top of the clamp 901. The first threaded hole 902 is internally threaded with a fastening bolt 903. The bottom end of the clamp 901 has a The first bolt seat 904 is welded at the side position, which is convenient for fixing the clamp 901. The outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com