Method and equipment for controlling non-intelligent electronic actuator of variable-section supercharger

An electronic actuator, non-intelligent electronic technology, applied in mechanical equipment, engine control, machine/engine, etc., can solve problems such as blade operating range changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

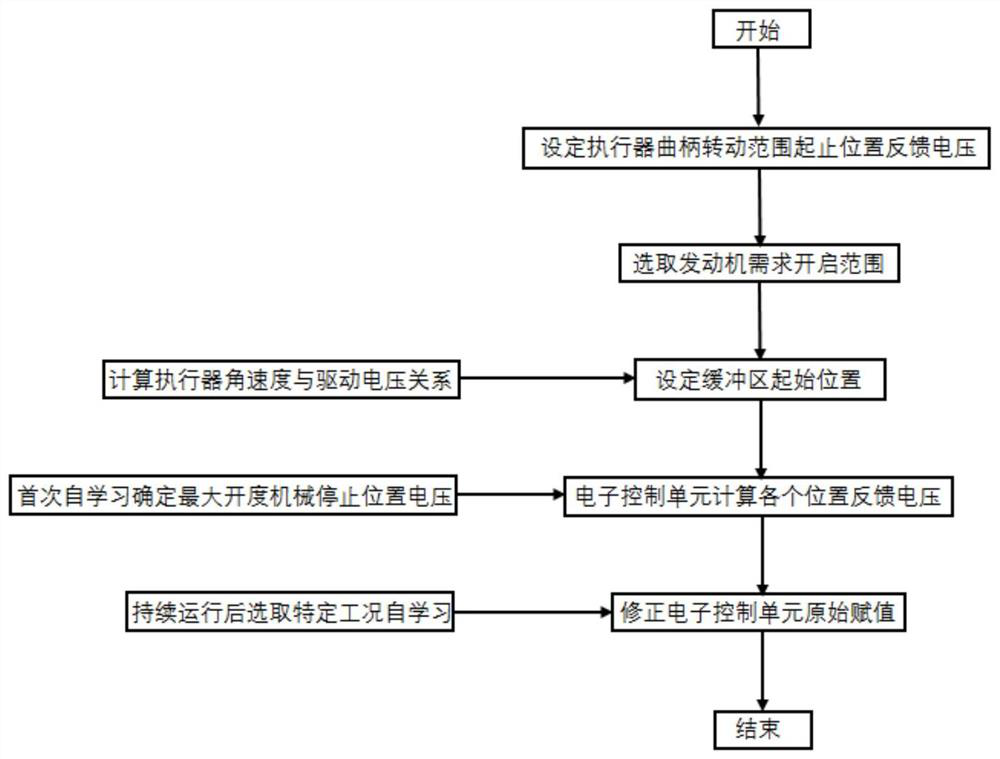

[0041] Such as figure 2 Shown, a specific embodiment that the present invention proposes is as follows:

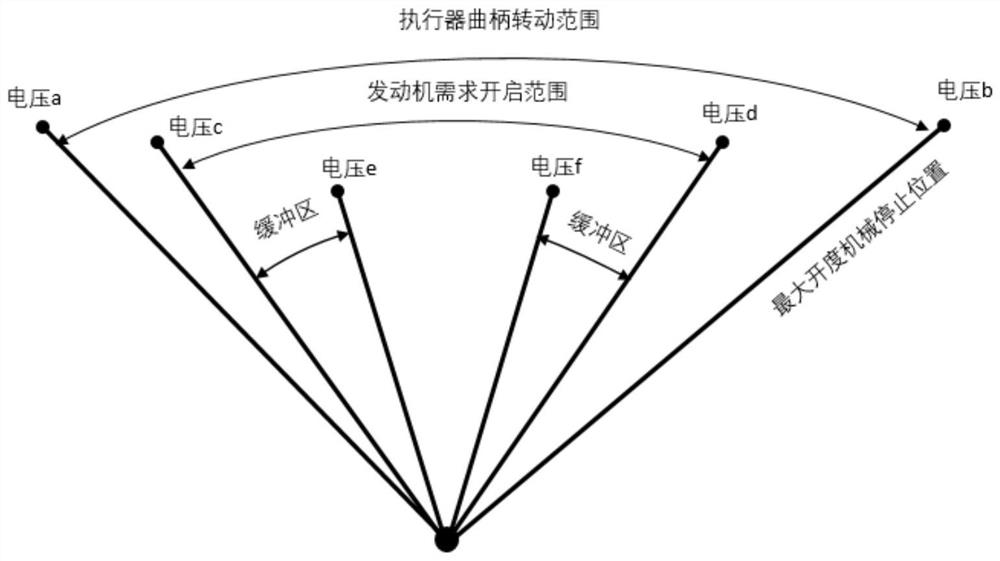

[0042] 1. According to the mechanical characteristics of the supercharger itself, and considering the ECU power supply voltage, set the feedback voltage of the minimum flow position of the electronic actuator and the full-open mechanical stop position to 0.5V and 4.7V respectively, and the supercharger operates at the minimum flow position, The fully open mechanical stop position can provide booster pressure ratios of 0.3 and 2, respectively.

[0043] 2. The required pressure ratio of the actual air intake of the engine is 0.5-1.8. When the supercharger reaches this required value, the feedback voltage of the electronic actuator is 0.7V and 4.5V respectively. The relationship between the driving range of the electronic actuator, the actual demand range, the starting and ending position feedback voltage and the ECU input voltage: 0<0.5<0.7<4.5<4.7<5V.

[0044] 3. Accordi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com