A Hydrogen Oxygen Igniter Using Glow Plug

A hydrogen-oxygen igniter and glow plug technology, which is applied to machines/engines, rocket engine devices, jet propulsion devices, etc., can solve the problems of electric igniter electromagnetic interference, limited ignition reliability, easy ablation of ignition components, etc. Achieve the effect of less electromagnetic interference, shorten production cycle, and reduce throttling components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

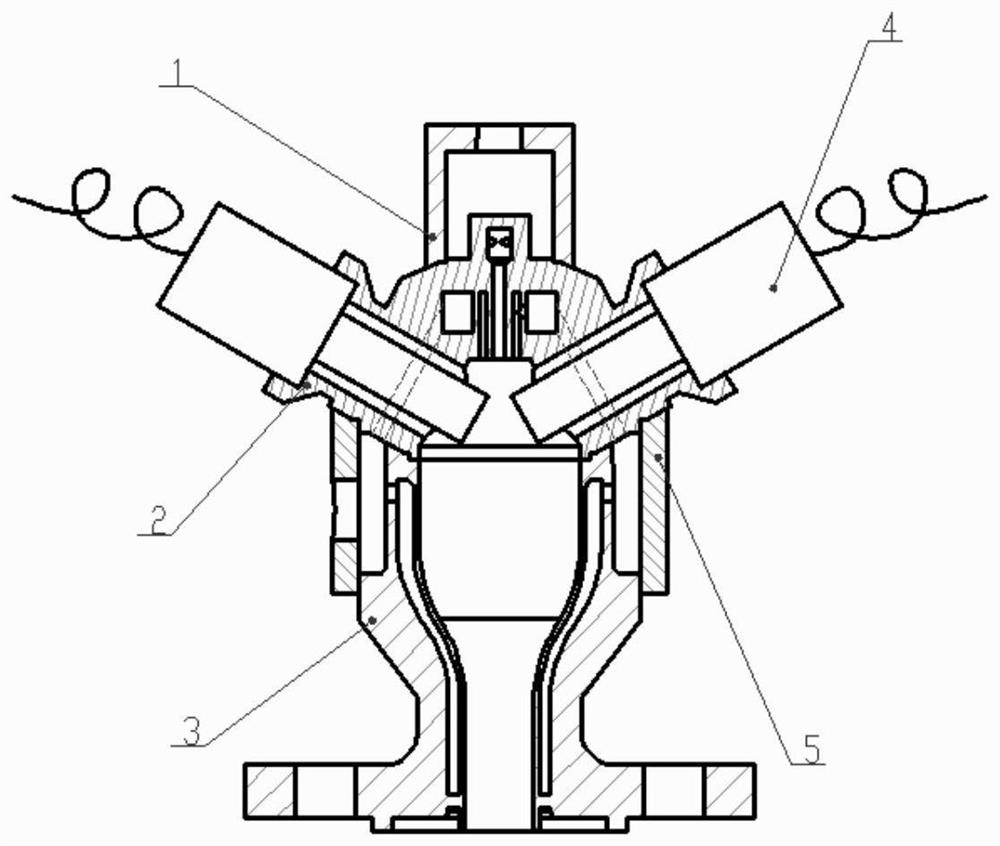

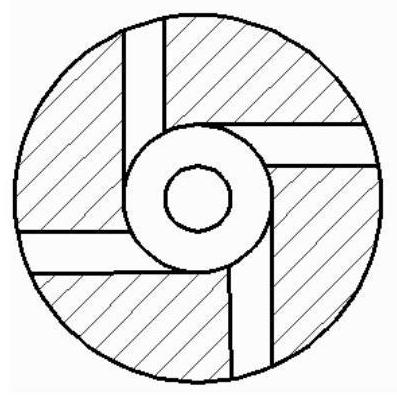

[0025] The present invention will be further elaborated below in conjunction with the accompanying drawings.

[0026] The present invention aims to design a hydrogen-oxygen torch igniter that uses a glow plug to ignite, has weak electromagnetic interference, is small in size, can be integrated with a power supply, and can be used in a wide range of working conditions and can work with high reliability. This igniter is designed with the concept of additive manufacturing, and the electric glow plug is used as the ignition source. Compared with the traditional electric spark ignition method, there is no electric actuator and other accessories, the electromagnetic interference is weak, the volume is small, and it is easy to integrate with the power supply. And the material of the glow plug is high-temperature-resistant ceramic material, no additional heat protection measures are required, and the structure of the igniter is greatly simplified. Compared with the spark plug electric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com