Wind tunnel device for prolonging operation time of hypersonic-speed temporary-flushing wind tunnel

A technology of temporary flushing wind tunnel and running time, which is applied in the direction of measuring devices, testing of machines/structural components, instruments, etc. Effective running time, extended running time, and low modification difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

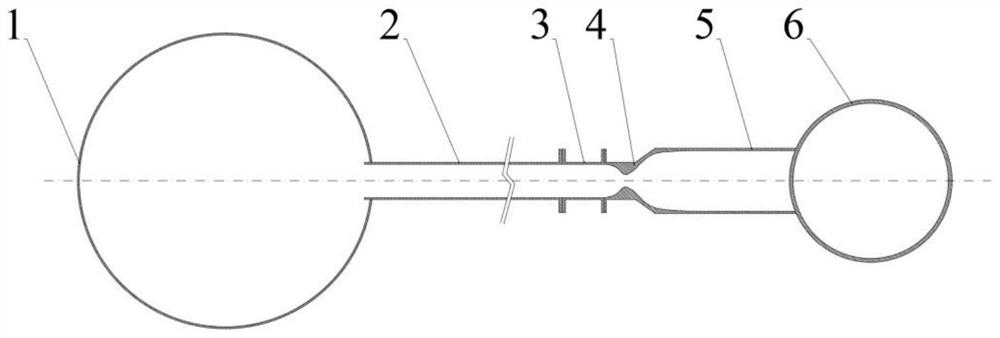

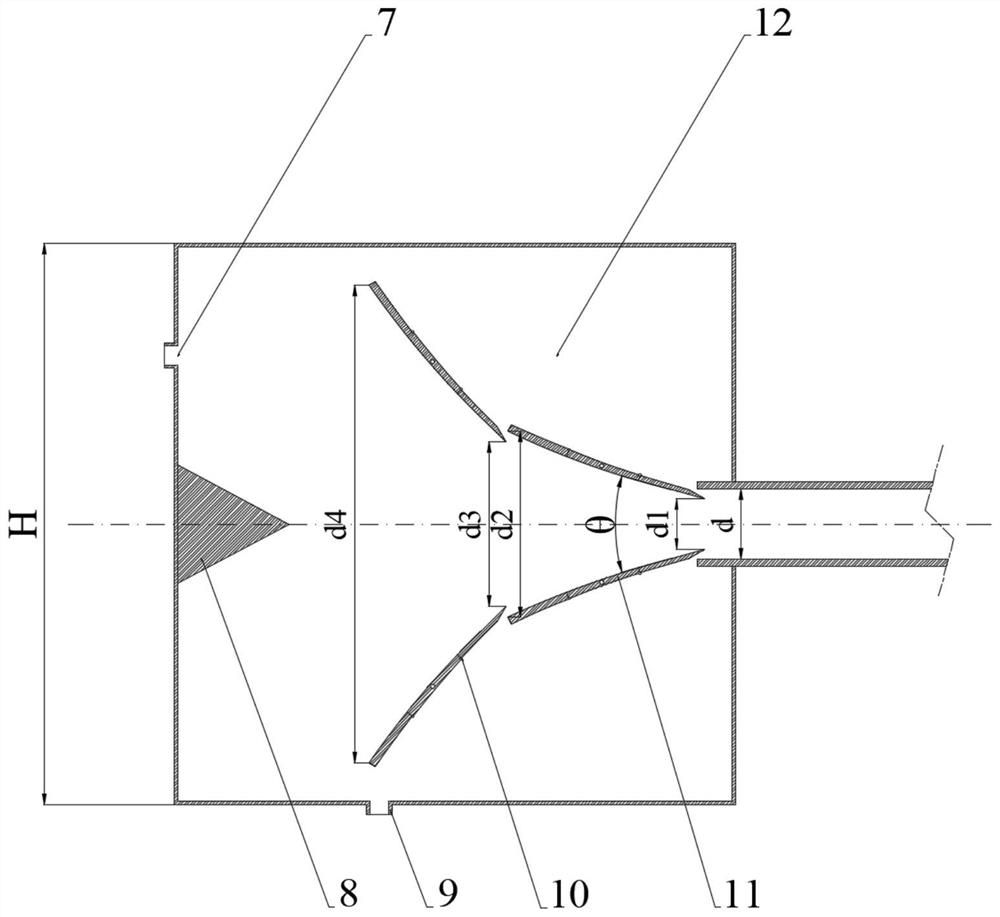

[0032] A wind tunnel device for prolonging the running time of a hypersonic transient wind tunnel, comprising: a gas storage tank, a gas storage section connected coaxially in sequence, a control valve, a nozzle, a test section and a vacuum tank; the tail extension of the gas storage section Into the air storage tank to communicate with the air storage tank in a sealed manner. The interior of the gas storage tank is equipped with a diversion cone and a diversion cone that are coaxial with the gas storage section; the front end of the diversion cone extends into the tail end of the gas storage section and is fixed; the diversion cone is fixed and installed on the gas storage tank The side coaxially opposite to the tail end of the gas storage section; the expansion wave generated by the nozzle passes through the gas storage section, the diversion cone and reaches the diversion cone in turn, and the diversion cone separates the expansion wave and reflects it to the reservoir Both...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com