Joint detection chip kit

A kit and chip technology, applied in the field of joint inspection chip kits, can solve problems such as cross-contamination of samples, empty reaction membranes, and impact on contact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below, the specific structure of the joint detection chip kit of the present application will be described in detail with reference to the drawings.

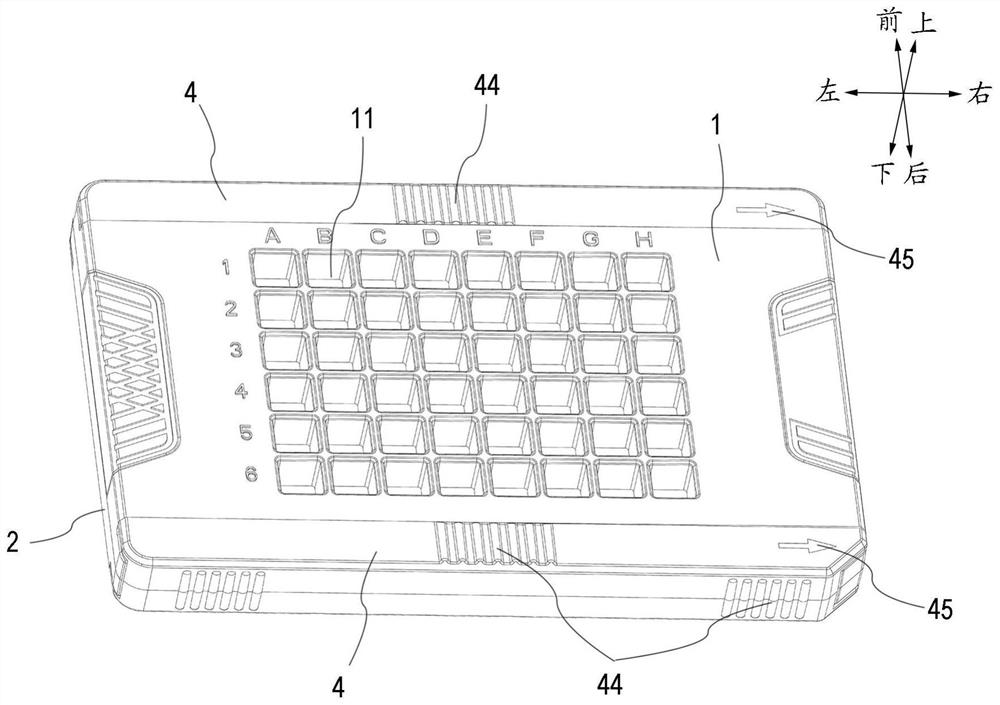

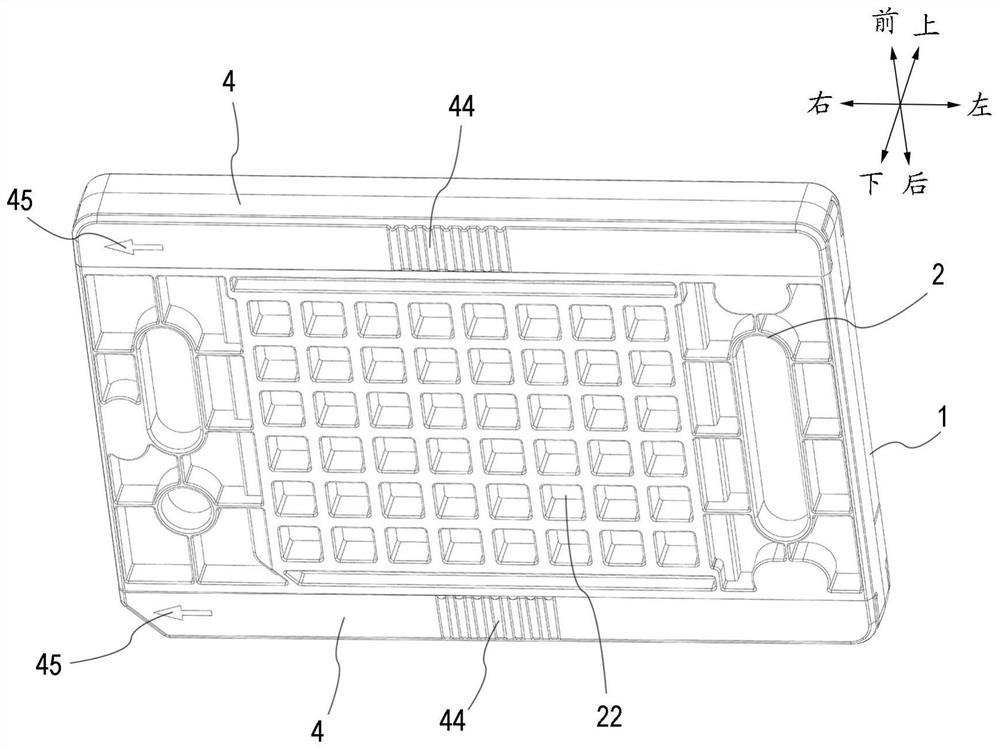

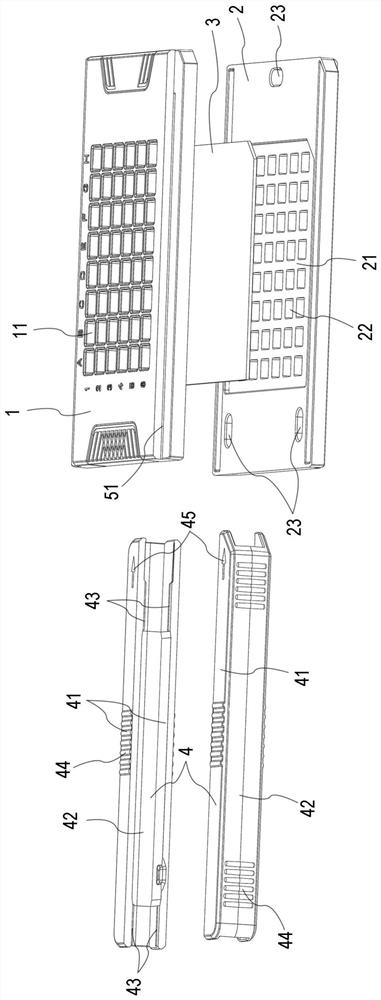

[0035] figure 1 It is a schematic diagram of the structure of the joint inspection chip kit of this application; figure 2 It is a schematic structural diagram of the bottom direction of the joint inspection chip kit of this application; image 3 for figure 1 Schematic diagram of the disassembled state of each part. Such as figure 1 , figure 2 , image 3 As shown, the joint inspection chip includes: the same rectangular cover plate 1 and base plate 2, the middle position of the upper surface of the base plate 2 is provided with a reaction tank 21, the reaction tank 21 is provided with a A detection film 3 that produces a non-specific reaction with colorants and the like. The cover plate 1 is closed on the base plate 2, and the front and rear ends are fixed by fixing strips 4, so that the cover plate 1 can be tight...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com