Infrared image defect edge detection method based on improved mathematical morphology

A mathematical morphology and edge detection technology, applied in image enhancement, image analysis, image data processing, etc., can solve problems such as failure of ferromagnetic material components, economic losses, etc., achieve noise suppression, good effect, and overcome poor anti-noise effect Effect

Pending Publication Date: 2021-06-22

KUNMING UNIV OF SCI & TECH

View PDF3 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

This will cause the original defect to expand at a very fast speed due to lack of timely intervention, which will directly lead to irreversible failure of the ferromagnetic material component as a whole, causing huge economic losses to all parties

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

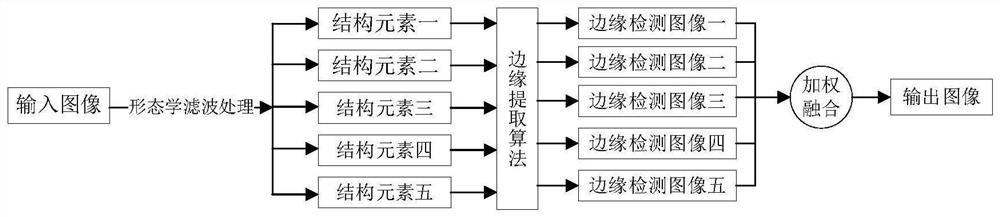

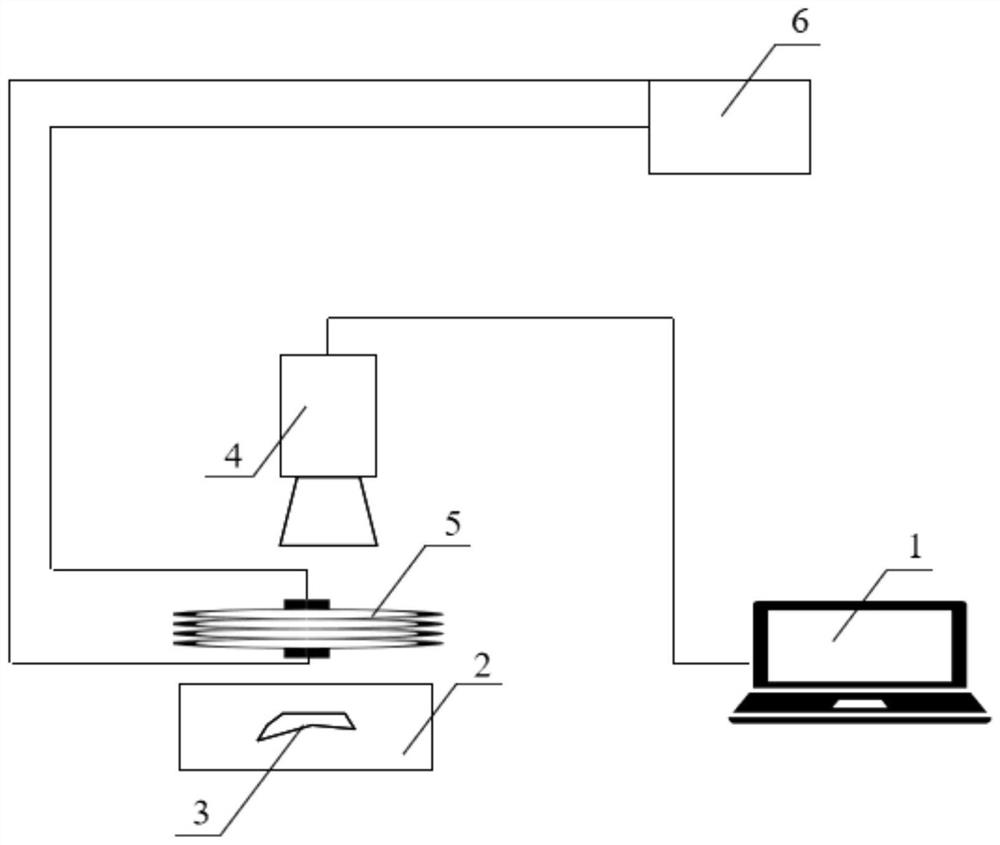

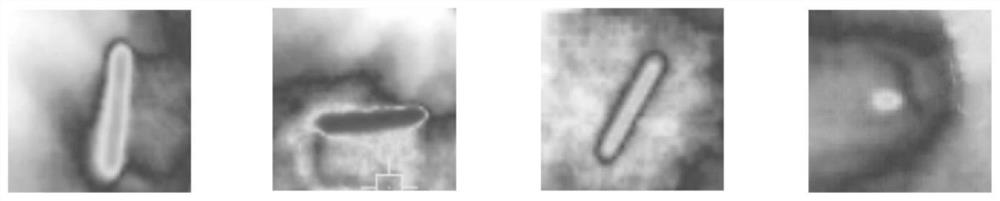

[0023] Embodiment 1: as Figure 1-6 Shown, a kind of infrared image defect edge detection method based on improved mathematical morphology, the concrete steps of described method are as follows:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses an infrared image defect edge detection method based on improved mathematical morphology, which is characterized in that a pulsed eddy current nondestructive heating device is applied to ferromagnetic material damage detection; eddy current heating is performed on a test piece, and the damage characteristics of the test piece are represented in the form of a thermal image. The invention has the advantages that a detected object does not need to be contacted, the thermal imaging result is intuitive and clear, the detection efficiency is high, and a larger range can be detected in a shorter time; an infrared image of a ferromagnetic test piece is filtered and segmented by using a multi-scale and multi-direction mathematical morphology edge detection method, and the processing and experimental results show that the method has better image denoising and image segmentation effects than edge detection results of a Roberts operator and a Prewitt operator. The defect of poor anti-noise effect in edge detection is overcome, the noise in the image is effectively inhibited, the defect position in the image is accurately detected, and the edge information of the defect is reserved.

Description

technical field [0001] The invention relates to an infrared image defect edge detection method based on improved mathematical morphology, which belongs to the fields of non-destructive testing and image recognition. Background technique [0002] Due to the continuous change and update of today's science and technology, the application of non-destructive testing technology in the field of modern industrial testing is becoming more and more common. Non-destructive testing technology is an indispensable technology in various fields. Non-destructive testing is the detection of the state of equipment test pieces, which can reduce accidents to a certain extent. Non-destructive testing technology can also effectively prevent various economic losses caused by equipment damage. It is of great significance to improve product quality and provide important guarantees for the safe operation of engineering equipment in actual production and life. [0003] The actual engineering environm...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G06T7/00G06T7/13G06T5/00

CPCG06T7/0002G06T7/13G06T2207/10048G06T5/70

Inventor 邹金慧蔡敏吴建德

Owner KUNMING UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com