Permanent magnet series-parallel connection type variable magnetic circuit adjustable magnetic flux motor

A flux motor and permanent magnet technology, applied in the direction of magnetic circuit, magnetic circuit rotating parts, magnetic circuit static parts, etc., can solve the problem of low power density and low coercivity permanent magnet magnetization of parallel adjustable flux motor Difficult state adjustment, volume increase, etc., to achieve the effect of small magnetizing current, stable working point, and small demagnetization current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

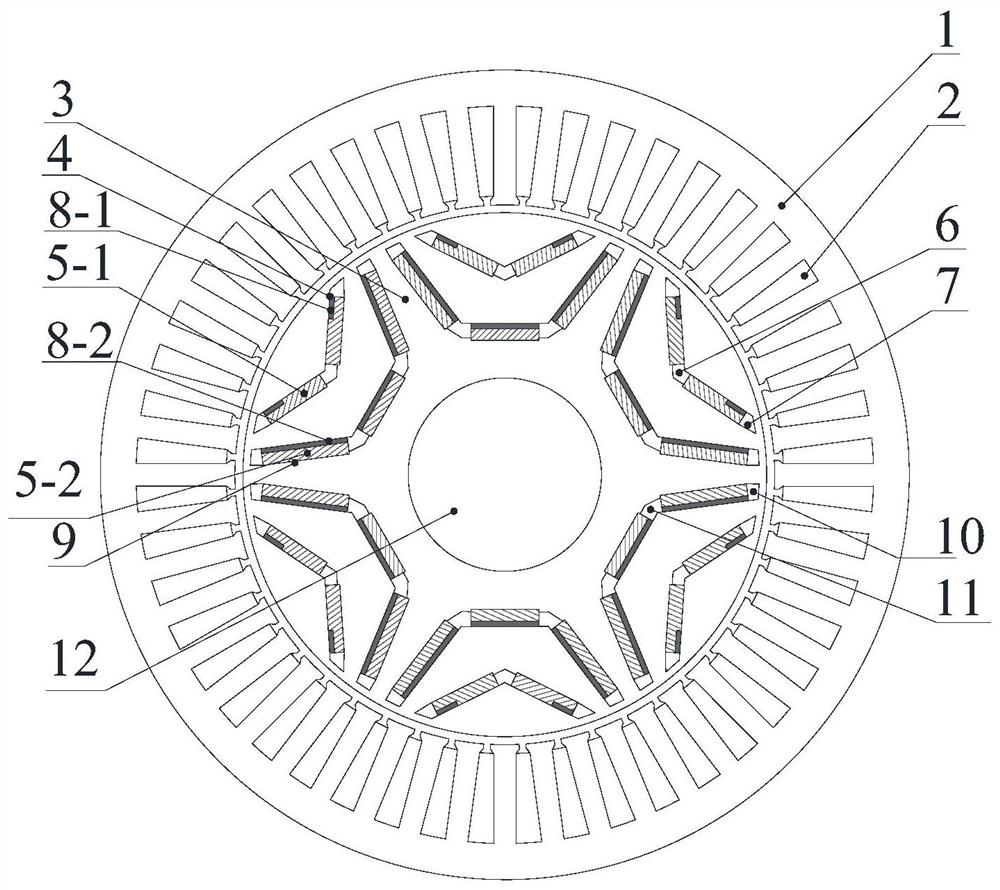

[0028] Specific implementation mode one: the following combination Figure 1-4 To illustrate this embodiment, the permanent magnet series-parallel variable magnetic circuit adjustable flux motor of the present invention includes a stator core 1, an armature winding 2, a rotor core 3 and a rotating shaft 12; the rotor core 3 is fixed on the rotating shaft 12, and the motor The pivot winding 2 is located in the stator core 1 .

[0029] Also includes V-shaped permanent magnet slot 4, low-coercivity permanent magnet, U-shaped permanent magnet slot 9, high-coercivity permanent magnet, No. 1 magnetic isolation slot 6, No. 2 magnetic isolation slot 7, and No. 3 magnetic isolation slot 10 and No. 4 magnetic isolation slot 11;

[0030] Five low-coercivity permanent magnets and five high-coercivity permanent magnets are arranged under each magnetic pole, and the five low-coercivity permanent magnets are respectively two No. 1 low-coercivity permanent magnets 5-1 and three No. 2 permane...

specific Embodiment approach 2

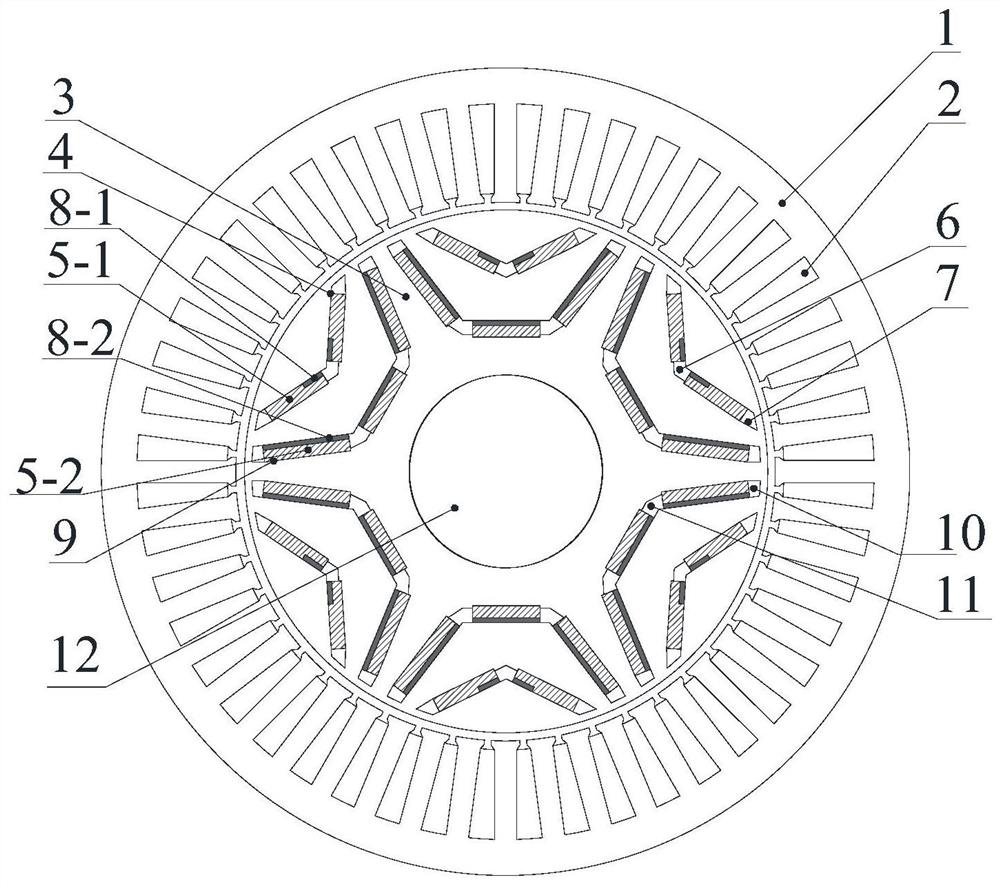

[0037] Specific embodiment two: The difference between this embodiment and embodiment one is that two No. 1 high-coercivity permanent magnets 8-1 are positioned at the V-shaped inner side and close to the bottom angle of the V-shaped permanent magnet groove 4 grooves, two pieces The No. 1 high-coercivity permanent magnet 8-1 is symmetrically arranged in the V-shaped permanent magnet slot 4 with the rotor direct axis as the symmetric line, the V-shaped included angle is 30-170 degrees, and the remaining space in the V-shaped permanent magnet slot 4 It is the No. 1 low-coercive force permanent magnet 5-1; three No. 2 high-coercive force permanent magnets 8-2 are placed on the upper layer (U-shaped inner side) of the U-shaped permanent magnet groove 9, and three No. 2 low-coercive force permanent magnets The permanent magnet 5-2 is placed on the lower floor (U-shaped outside) of the U-shaped permanent magnet groove 9, that is, the two are arranged side by side along the thickness ...

specific Embodiment approach 3

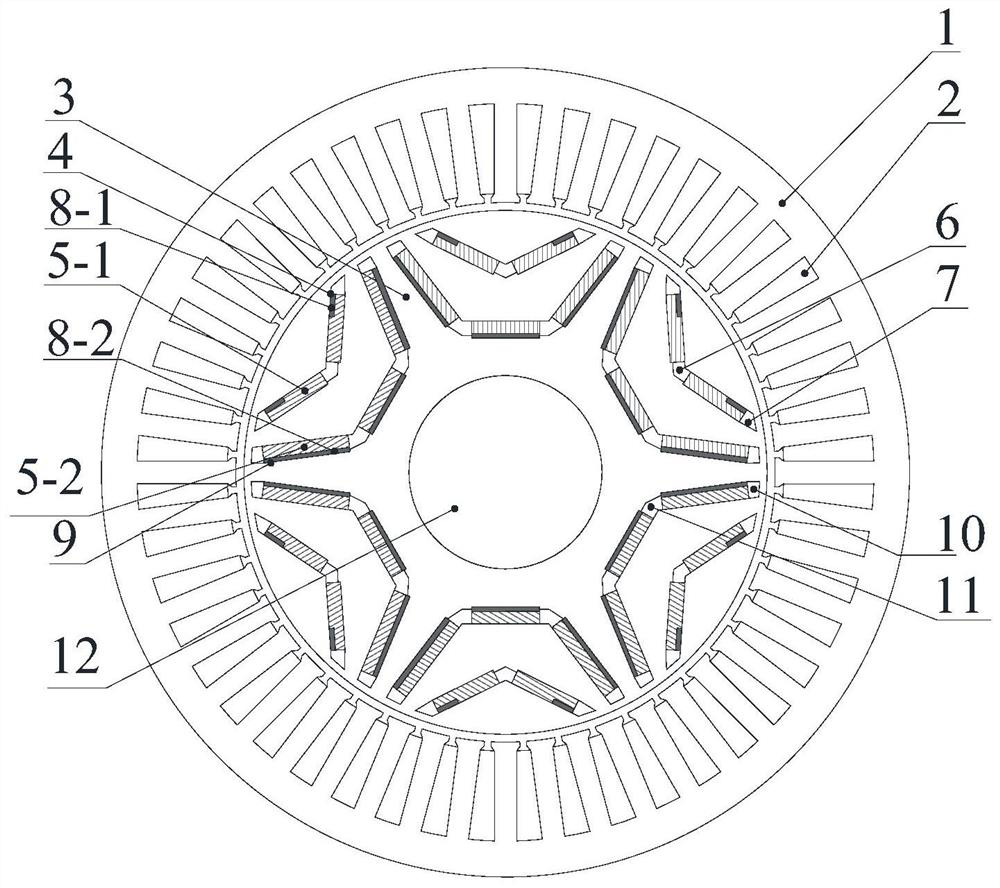

[0038] Specific embodiment three: the difference between this embodiment and embodiment one is that two No. 1 high-coercive force permanent magnets 8-1 are located at the V-shaped inner side and near the two ends of the V-shaped permanent magnet groove 4 notch , two No. 1 high-coercivity permanent magnets 8-1 are symmetrically arranged in the V-shaped permanent magnet slot 4 with the rotor direct axis as the symmetric line, the V-shaped included angle is 30-170 degrees, and the V-shaped permanent magnet slot 4 The remaining space in the interior is No. 1 low-coercivity permanent magnet 5-1; No. 3 No. 2 high-coercivity permanent magnets 8-2 are placed on the lower floor (U-shaped outside) of U-shaped permanent magnet groove 9, and No. 3 No. 3 lower The coercivity permanent magnet 5-2 is placed on the upper layer (U-shaped inside) of the U-shaped permanent magnet groove 9, and the included angle of the U-shaped permanent magnet groove 9 is adjustable.

PUM

| Property | Measurement | Unit |

|---|---|---|

| coercivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com