Foam spraying, cleaning and sucking device for automobile foot mat

A technology for car floor mats and underframes, which is applied to cleaning methods and appliances, cleaning methods using liquids, cleaning methods using gas flow, etc., which can solve problems such as easy dirt, labor-intensive, and foam generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

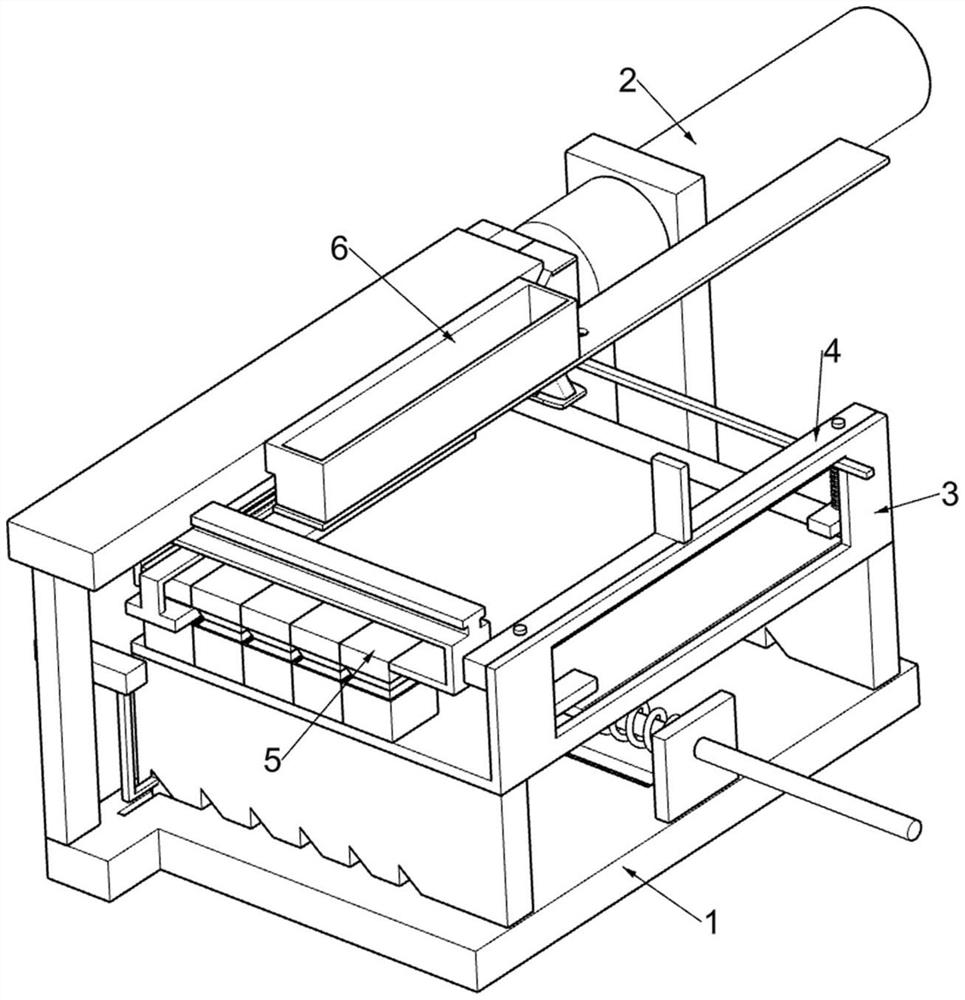

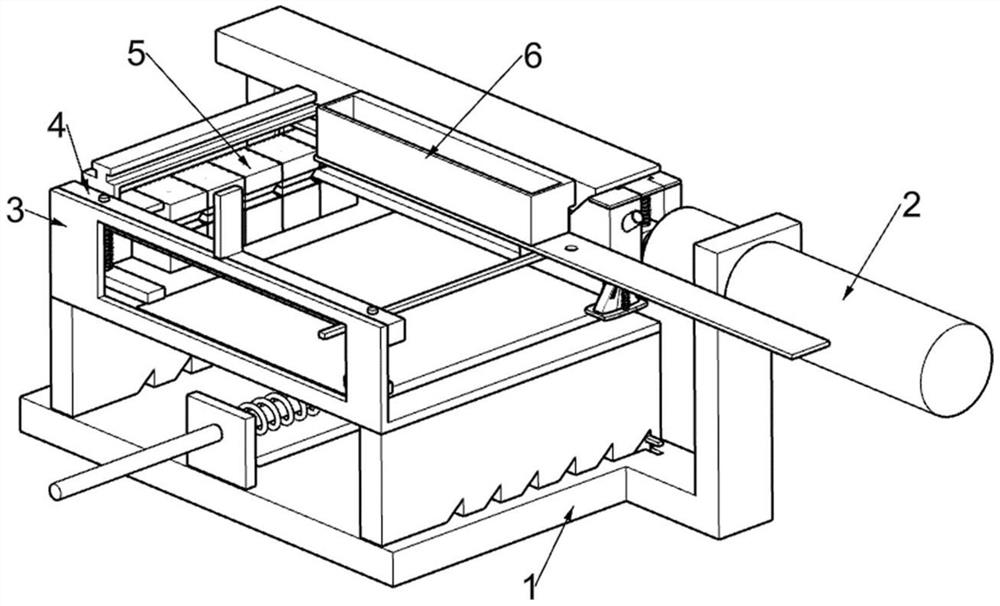

[0027] A kind of foam spray cleaning device for car mats, such as Figure 1-10 As shown, it includes a support chassis 1, a cleaning mechanism 2 and a clamping reset mechanism 3, the support chassis 1 is provided with a cleaning mechanism 2, and the cleaning mechanism 2 is used to remove the car floor mat on the second fixed plate 35. Clean up, the support base frame 1 is provided with a clamping reset mechanism 3, and the clamping reset mechanism 3 is used to make the suction port 26 reciprocatingly clean up every part of the car mat on the second fixed plate 35.

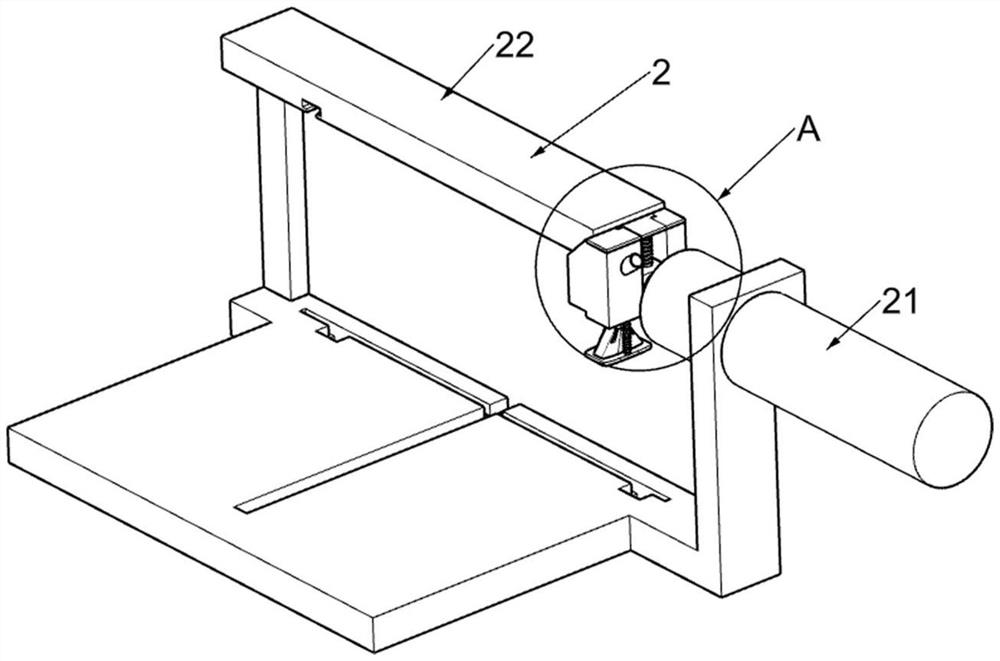

[0028] The cleaning mechanism 2 includes an electric push rod 21, a wedge frame 22, a first slide block 23, a first wedge block 24, a first return spring 25, a suction port 26, a first slide bar 27, a second return spring 28 and a hose 29. An electric push rod 21 is installed on the support base 1, and the electric push rod 21 is used to drive the first slider 23 and its upper device to reset, and the support base ...

Embodiment 2

[0033] On the basis of Example 1, such as Figure 7 As shown, it also includes a compression device 4, the compression device 4 is located on the support chassis 1, the compression device 4 is used to compress the automobile floor mat on the second fixed plate 35, the compression device 4 includes a fixed Bar 41, the first sliding bar 42, the second sliding bar 43, the pressing block 44 and the fifth return spring 45, the first wedge block 24 is fixedly connected with the fixed bar 41, and the fixed bar 41 is used to drive the first sliding bar 42 And the upper device moves downward, the first sliding bar 42 is slidably matched on the fixed bar 41, the first sliding bar 42 is slidably matched with the second fixed plate 35, and the first sliding bar 42 is slidably connected with two second Slide bar 43, the bottom end of the second slide bar 43 is provided with a compression block 44, and the compression block 44 is used to compress the automobile floor mat on the second fixed...

Embodiment 3

[0037] On the basis of Example 2, such as Figure 8 As shown, it also includes a pushing device 5, the pushing device 5 is arranged on the support chassis 1, and the pushing device 5 includes a second fixed block 51, a second sliding bar 52, a sliding bar 53, a third fixing block 54, a fourth Fixed block 55, the second slide block 56, the 6th back-moving spring 57 and wedge plate 58, wedge frame 22 bottoms are provided with the second fixed block 51, and the second fixed block 51 is used to prevent the second slide bar 52 and its upper device to Moving down, the sliding type on the second fixed block 51 is equipped with a second sliding bar 52, and the second sliding bar 52 is used to drive the wedge-shaped plate 58 and its upper device to reciprocate, and the sliding type on the wedge-shaped frame 22 is equipped with a sliding bar 53. The bottom of the bar 53 is provided with a third fixed block 54, the bottom of the third fixed block 54 is slidably connected with five second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com