Sleeve coiling device

The technology of a sleeve and an outer cylinder is applied in the field of the sleeve winding device, which can solve the problems of lack of friction force for the strip material, the curved surface is not large enough, the strip material is not easy to bend, etc., and achieves a large winding thickness and a large friction force. , Improve the effect of rolling friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A sleeve rolling device is used for manual rolling.

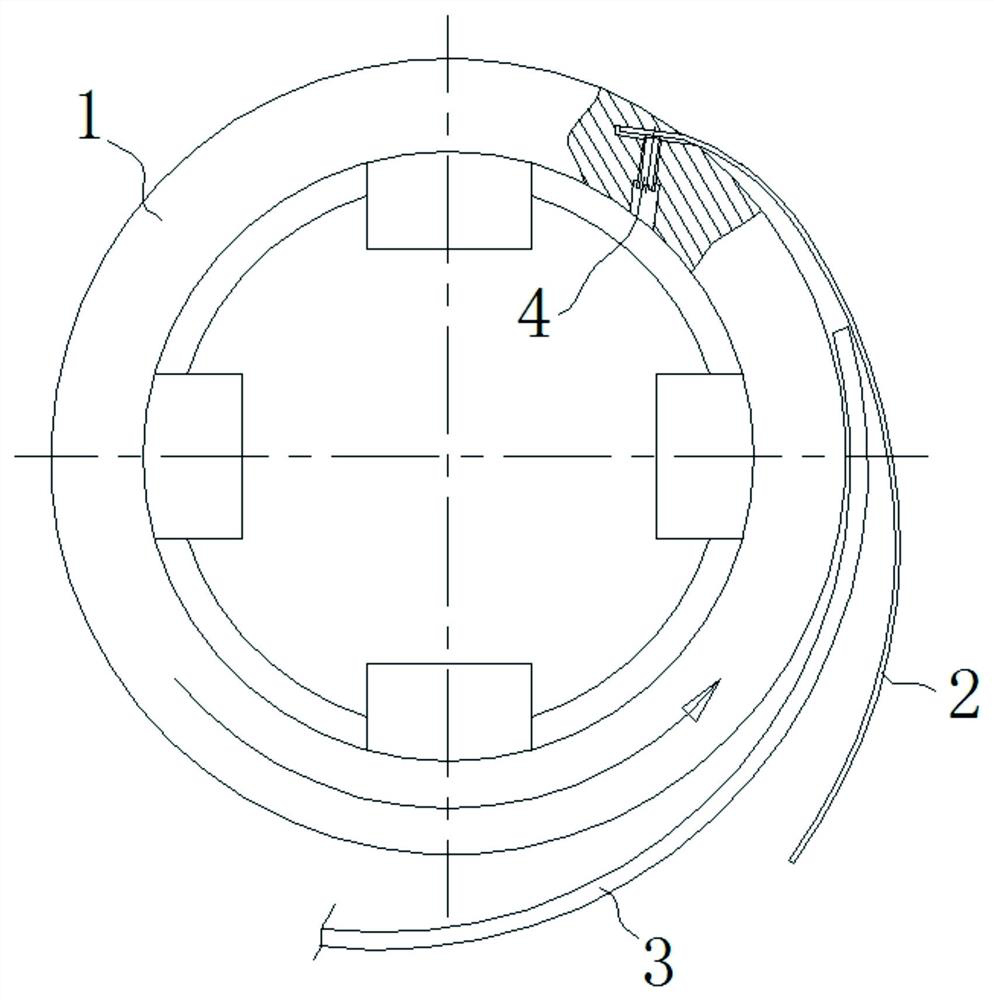

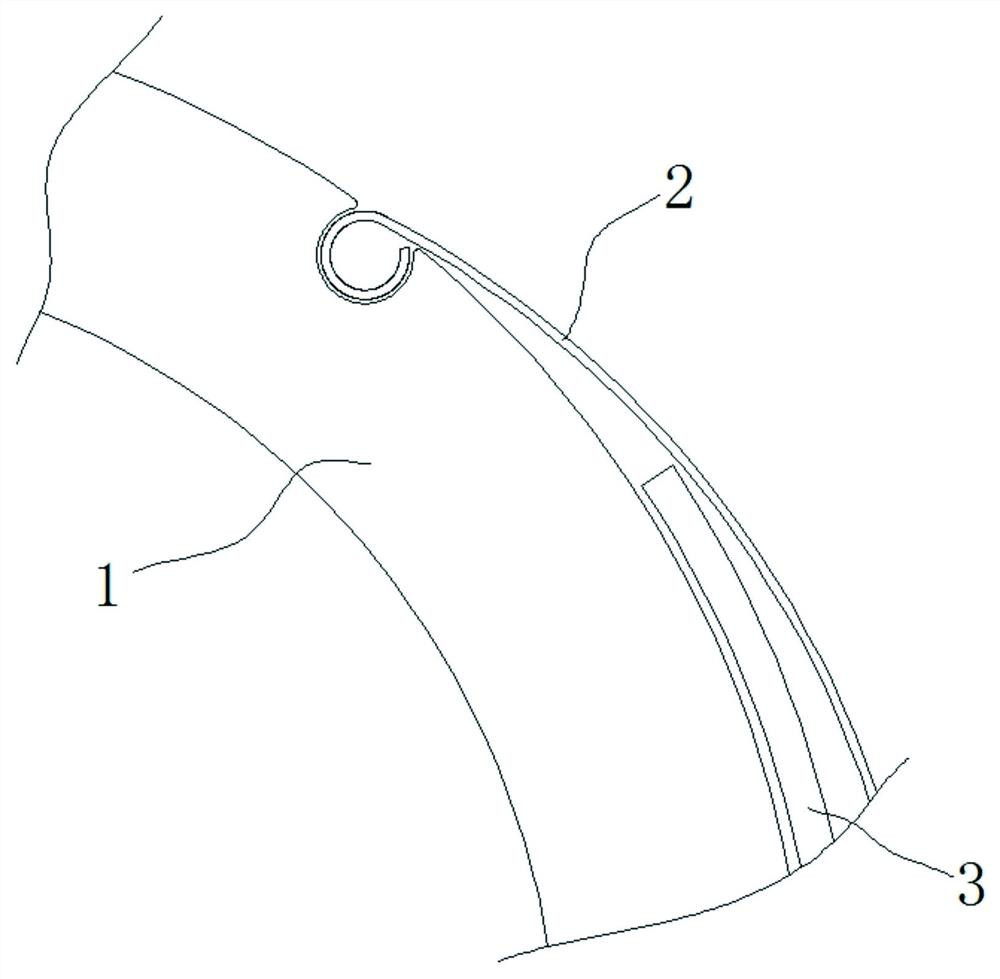

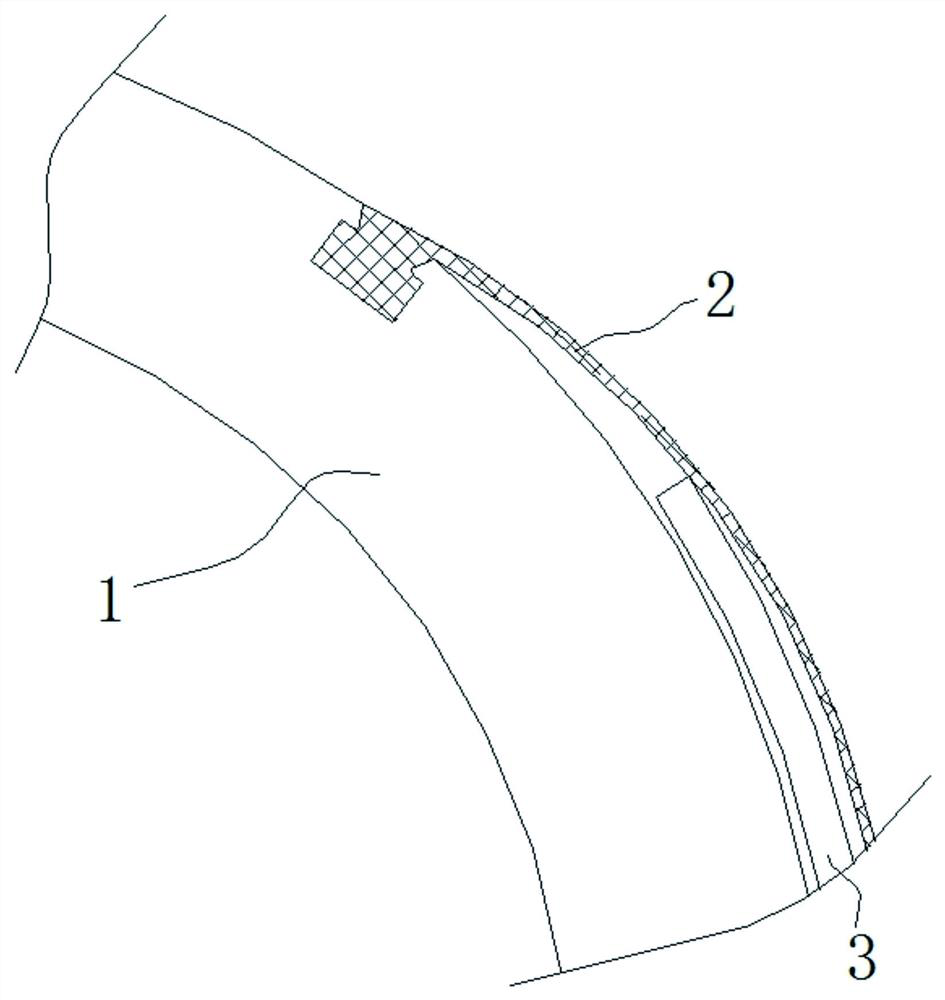

[0028] Such as figure 1 As shown, the sleeve 1 is installed on the main shaft of the coiler, and the main shaft tightens the inner surface of the sleeve 1 through the inner support mechanism, so that the sleeve 1 rotates with the main shaft. The material of the sleeve 1 is metal, which has good rigidity, and is used to support the winding of the metal strip on it. In this embodiment, the metal strip to be wound is a steel strip. Entrainment strip 2 is wound on the outer surface of sleeve 1. In order to prevent the entrainment strip 2 from causing crush to the metal strip, the material of entrainment strip 2 is soft copper or rubber, and its thickness is 1 / 4 of the thickness of the metal strip. one. The head end of the entrainment strip 2 is connected to the sleeve 1, and the rest of the entrainment strip 2 is used to enclose the head 3 of the metal strip, so that the metal strip is wound on the sleeve 1.

[0029] ...

Embodiment 2

[0036] A sleeve rolling device, the difference from Embodiment 1 is that this rolling device is used to assist rolling.

[0037] Such as Figure 5As shown, in addition to the structure described in Embodiment 1, the winding device also includes a pressure roller 5 and a pair of pinch rollers 7 . A pair of pinch rollers 7 are arranged on the lower right side of the sleeve 1, one of which is fixed, and the other pinch roller 7 is driven by the cylinder 6 to clamp the belt 2. When the sleeve 1 rotates, the pair of pinch rollers The tight roller 7 tensions the entrainment belt 2, and plays the role of manually tightening the entrainment belt 2 downwards in the embodiment 1. Compared with the embodiment 1, the labor intensity of this method is lower and safer.

[0038] A pressing roller 5 is arranged on the right side of the sleeve 1, and the pressing roller 5 is driven by another air cylinder 6. As the diameter of the roll changes, the air cylinder 6 can elastically press the ent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com